A kind of slub yarn and its production method

A production method and technology of slub yarn, applied in the field of textile yarn, can solve problems such as the comfort of fabrics with the same composition and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] In this embodiment, the first roving for producing the base yarn is a roving made of 100% cotton white fiber, and the basis weight is 5.2g / 10m.

[0096] In this embodiment, the second roving for producing additional slub yarn is 100% white polyester roving, and the basis weight is 5.2 g / 10m.

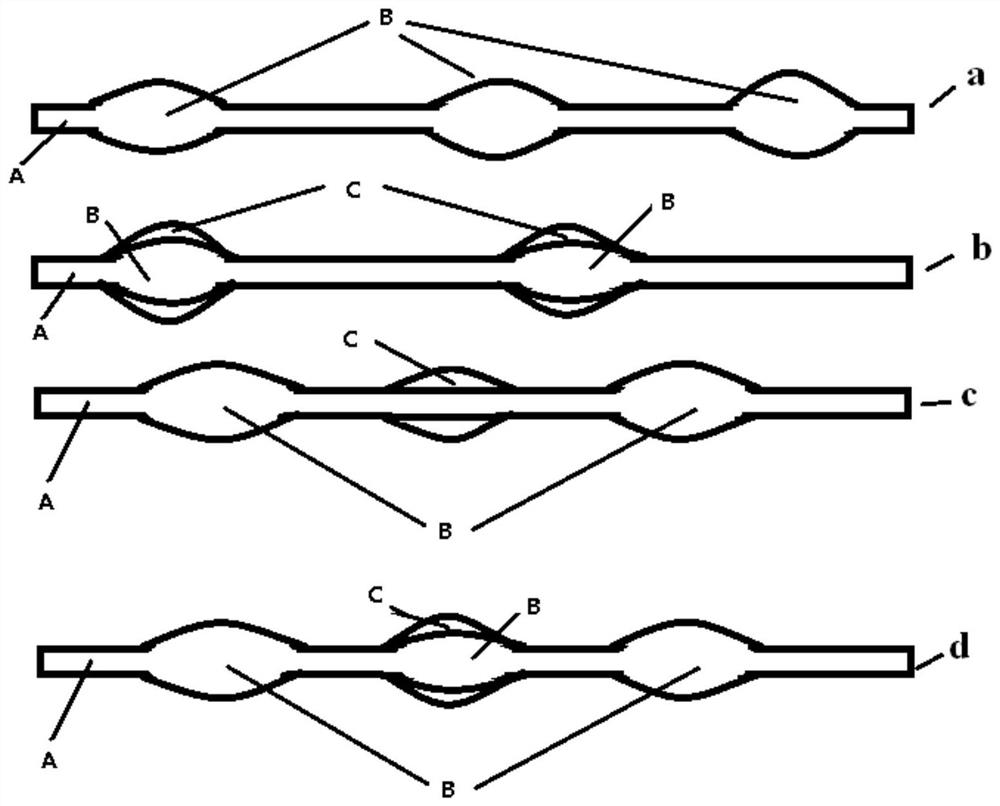

[0097] For the yarn prepared in this embodiment, along the length direction of the yarn, the process of the base yarn slub produced by the first roving is as follows: 1.5 times; the magnification of the additional slub yarn in the slub part is 0.5 times, and the overall magnification of the slub yarn is 2 times the slub yarn.

[0098] The dry basis weight of the spun yarn obtained in the spinning process is 1.97 g / 100 meters. The draft ratio of spinning process is 33 times. The twist in the spinning process is 780T / m. The spindle speed of spinning frame is 13000~14000r / min.

[0099] The winding process is carried out on an automatic winding machine to wind into a cone-shaped b...

Embodiment 2

[0103] In this embodiment, the first roving for producing the base yarn is a roving made of 100% cotton black fiber, and the basis weight is 5.2g / 10m.

[0104] In this embodiment, the second roving for producing additional slub yarn is a roving made of 100% cotton white fiber, and the basis weight is 5.2 g / 10m.

[0105] For the yarn prepared in this embodiment, along the length direction of the yarn, the process of the base yarn slub produced by the first roving is as follows: 1.5 times; the additional magnification of the slub part of the additional slub yarn is 1 time, and the overall magnification of the slub yarn is 2.5 times of the slub yarn.

[0106] The dry basis weight of the spun yarn obtained in the spinning process is 1.97 g / 100 meters. The draft ratio of spinning process is 33 times. The twist in the spinning process is 780T / m. The spindle speed of spinning frame is 13000~14000r / min.

[0107] The winding process is carried out on an automatic winding machine to...

Embodiment 3

[0111] In this embodiment, the first roving for producing the base yarn is a roving made of 100% cotton white fiber, and the basis weight is 5.2g / 10m.

[0112] In the present embodiment, the second roving for producing additional slub yarn is a roving made of 100% cotton orange fiber, and the weight is 5.2g / 10m.

[0113] For the yarn prepared in this embodiment, along the length direction of the yarn, the process of the base yarn slub produced by the first roving is as follows: 1.3 times; the additional magnification of the slub part of the additional slub yarn is 0.7 times, and the overall magnification of the slub yarn is 2 times of the slub yarn.

[0114] The dry basis weight of the spun yarn obtained in the spinning process is 1.97 g / 100 meters. The draft ratio of spinning process is 33 times. The twist in the spinning process is 780T / m. The spindle speed of spinning frame is 13000~14000r / min.

[0115] The winding process is carried out on an automatic winding machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com