Flock print press-fit machine

A pressing machine and printing technology, applied in printing, typewriters, printing devices, etc., can solve problems such as inaccurate patterns, poor effects, and affecting printing quality, and achieve the effect of improving quality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

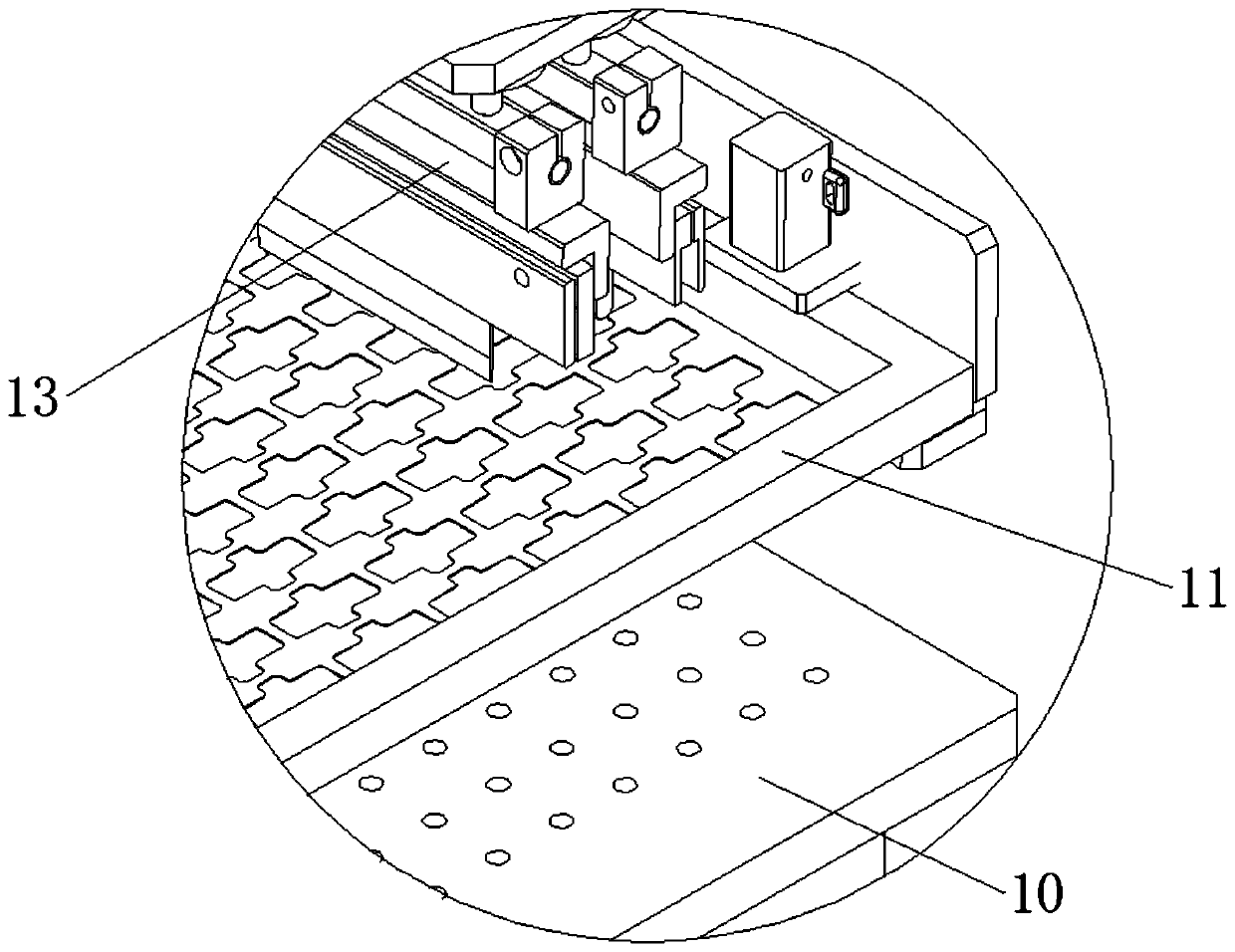

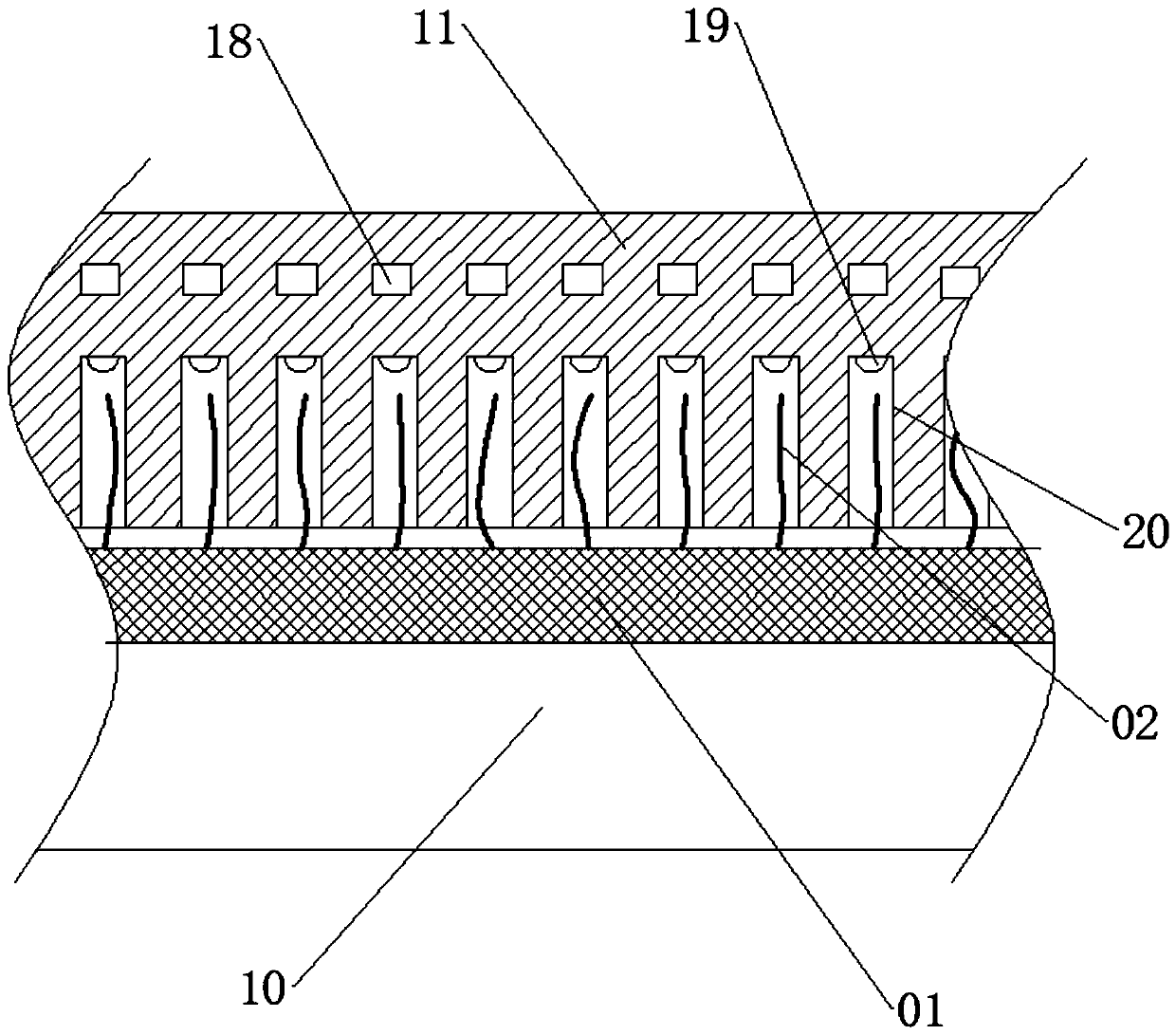

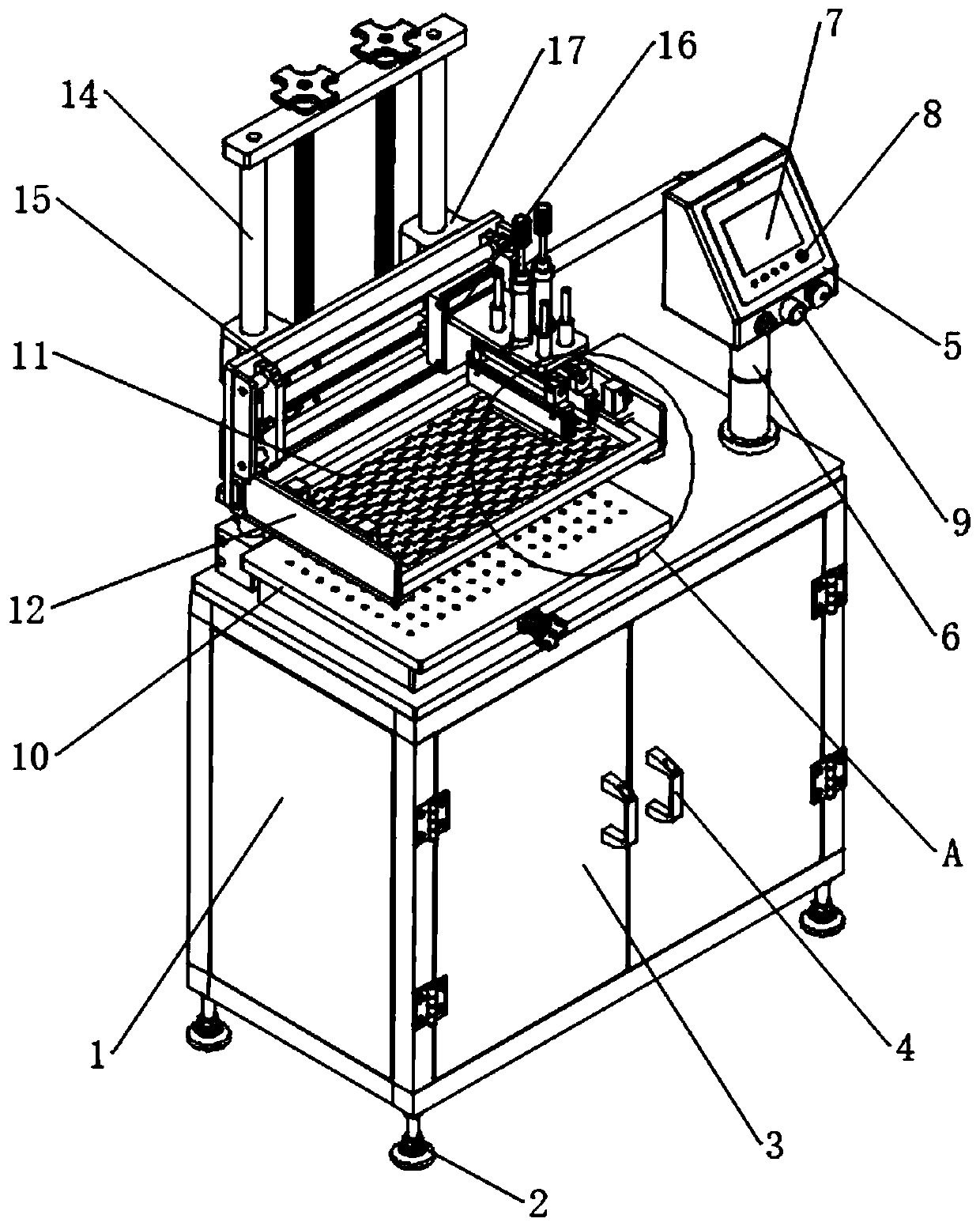

[0036] see Figure 1-3 , a flocking cloth printing pressing machine, comprising a base 1, a pressing base plate 10 is fixedly connected on the base 1, a pair of sliding bars 14 are fixedly connected on the base 1, a pair of sliding bars 14 are connected with a lifting mechanism 17, a pair of The lifting mechanism 17 is fixedly connected with the fixed plate 15 in the vertical direction, and the fixed plate 15 is fixedly connected with the microporous adsorption printing plate 11 in the horizontal direction, and the plane where the upper end of the pressing base plate 10 is located and the lower end of the microporous adsorption printing plate 11 The planes are parallel, and the fixed plate 15 is slidably connected with a dot-shaped electrostatic generator 13 corresponding to the microporous adsorption printing plate 11, and a sliding mechanism 16 is connected between the dot-shaped electrostatic generator 13 and the fixed plate 15, and the pressing bottom plate 10 The upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com