Positioning tool for miniaturized radio frequency power module eutectic welding and method of use thereof

A technology of radio frequency power and positioning tooling, applied in welding equipment, manufacturing tools, electric heating devices, etc., can solve the problems of poor flatness control, poor precision, and difficult positioning of printed boards, and achieve flexible expansion of design functions and accurate design positions Moreover, the effect of flexible design position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

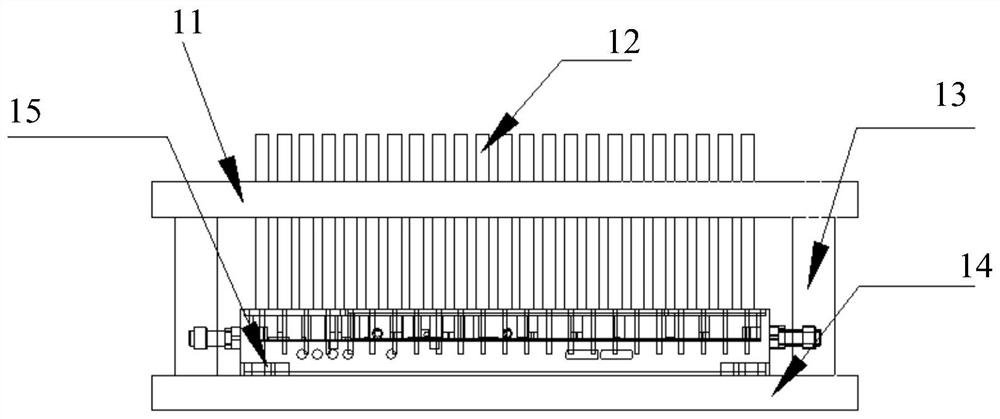

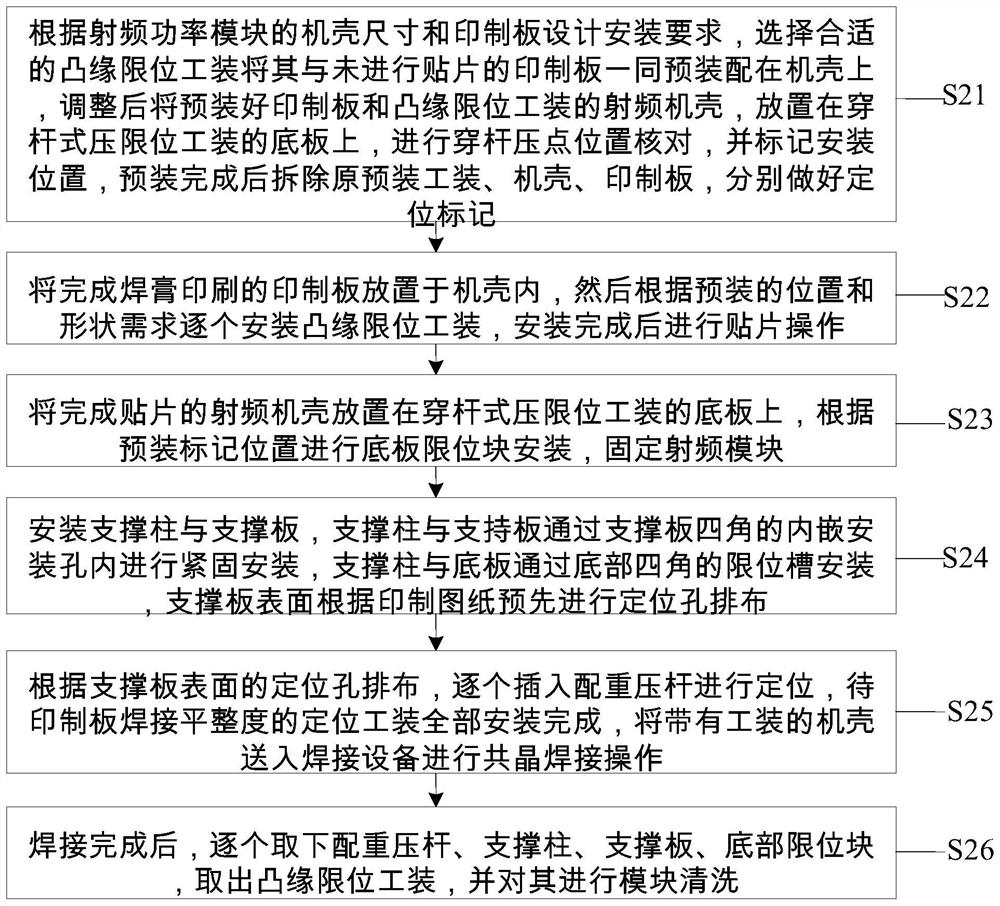

[0016] The positioning tool for miniaturized radio frequency power module eutectic welding proposed by the present invention and its usage method will be further described in detail below with reference to the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0017] The core idea of the present invention is that a positioning tool for eutectic welding of miniaturized radio frequency power modules provided by the present invention is completed by using two tools in cooperation, namely the flange limit tool and the through-rod pressure limit tool. Each tooling can be used alone or in combination under different working conditions; the flange limit toolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com