Assembled joist steel

An I-beam and assembled technology, applied in the field of steel, can solve difficult and dangerous problems, and achieve the effect of improving service life, increasing contact surface and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

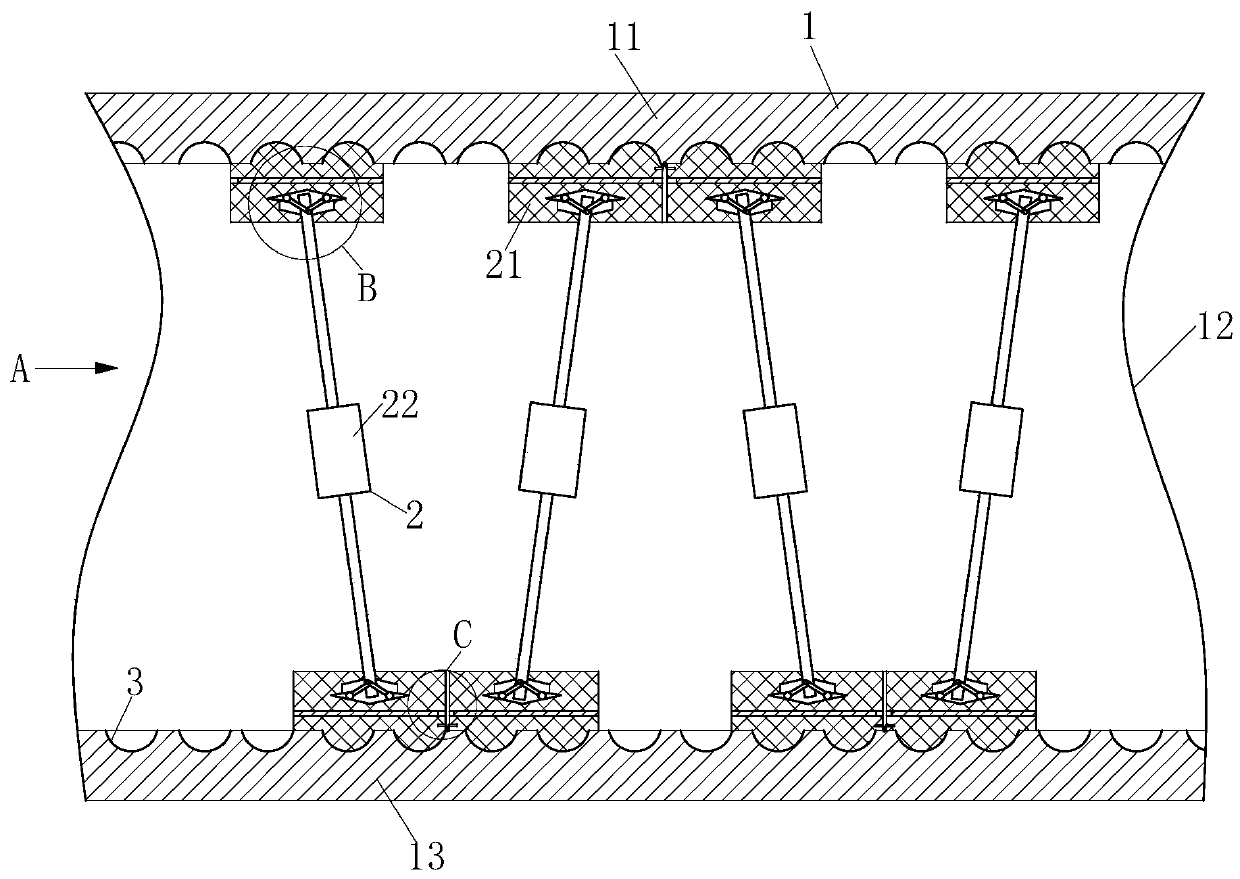

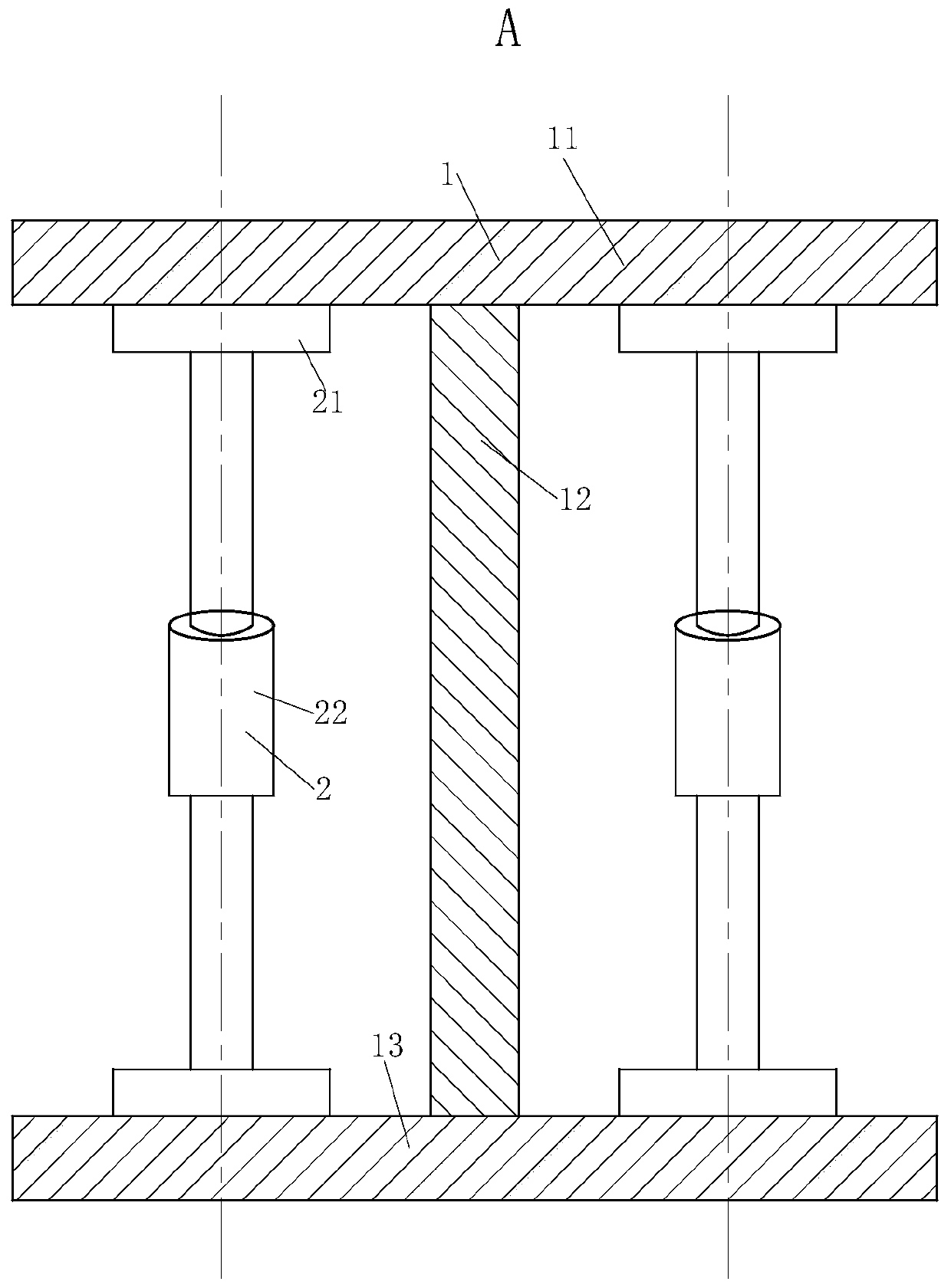

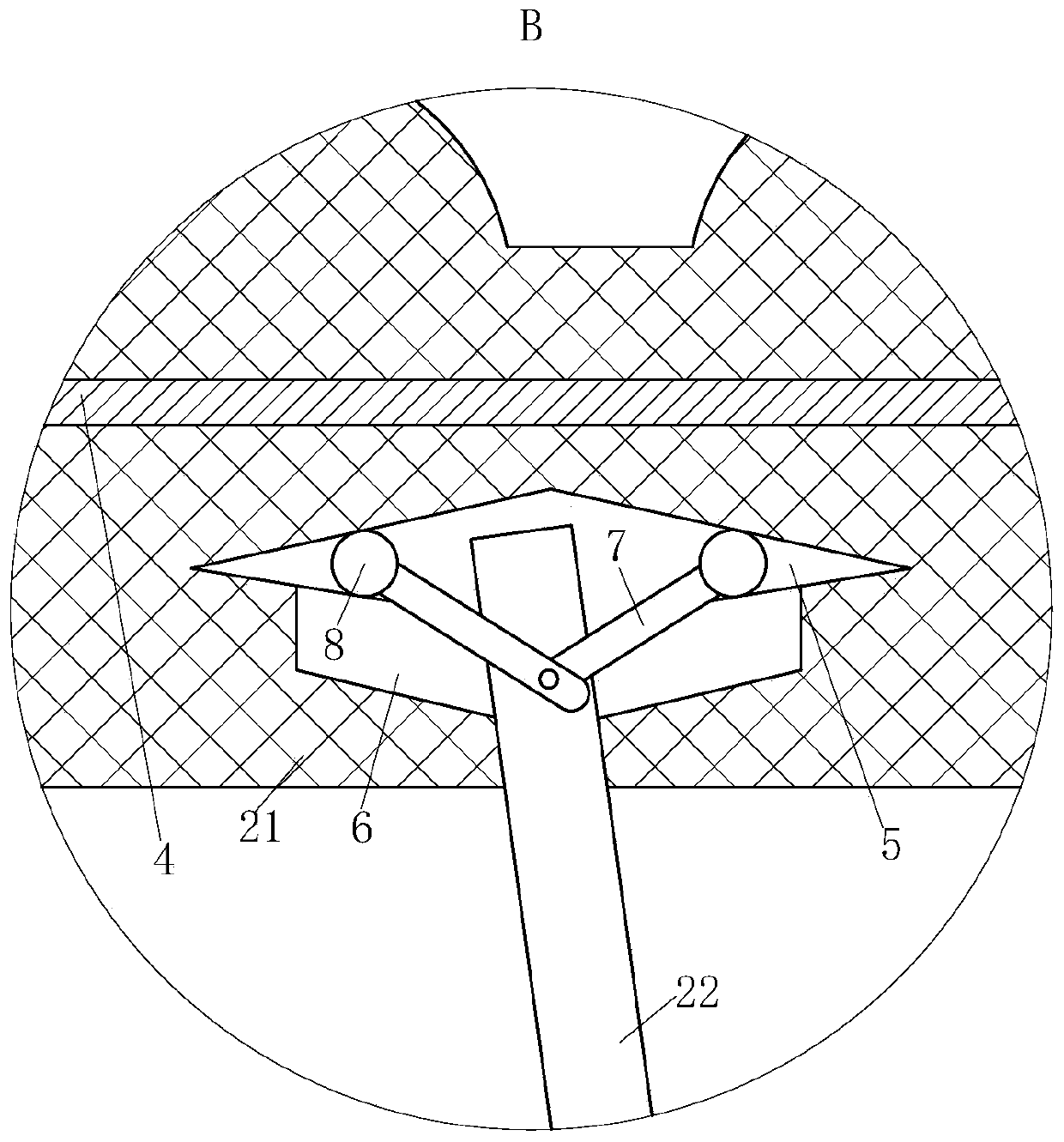

[0022] As an embodiment of the present invention, the support plate 21 is made of nylon material, and there is a No. 1 groove in the middle of the support plate 21. The metal plate 4 is fixedly installed in the No. 1 groove, and the through hole communicates with the No. 1 groove. The biaxial hydraulic cylinder 22 piston rod ends extend into the No. 1 groove through the through hole. The metal plate 4 in the No. 1 groove can be replaced with the material of the plate according to the supporting strength of the I-beam 1, and the replacement is convenient. The correction module 2 can be used for the correction of the I-beam 1 of different materials; the support plate 21 made of nylon and the I-beam The contact effect of 1 is good, and the support plate 21 made of nylon has toughness and is not easy to break; but the support plate 21 made of nylon has low support strength, low hardness, and is easy to bend; so the piston rod of the biaxial hydraulic cylinder 22 and the support pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com