Intelligent detection system and intelligent detection method applicable to alternating-current plugs

An AC plug-in and intelligent detection technology, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc., can solve the problem of low test efficiency of manual recording test data, achieve automatic submission of signal source CT disconnection to the management system, and save test time , to meet the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

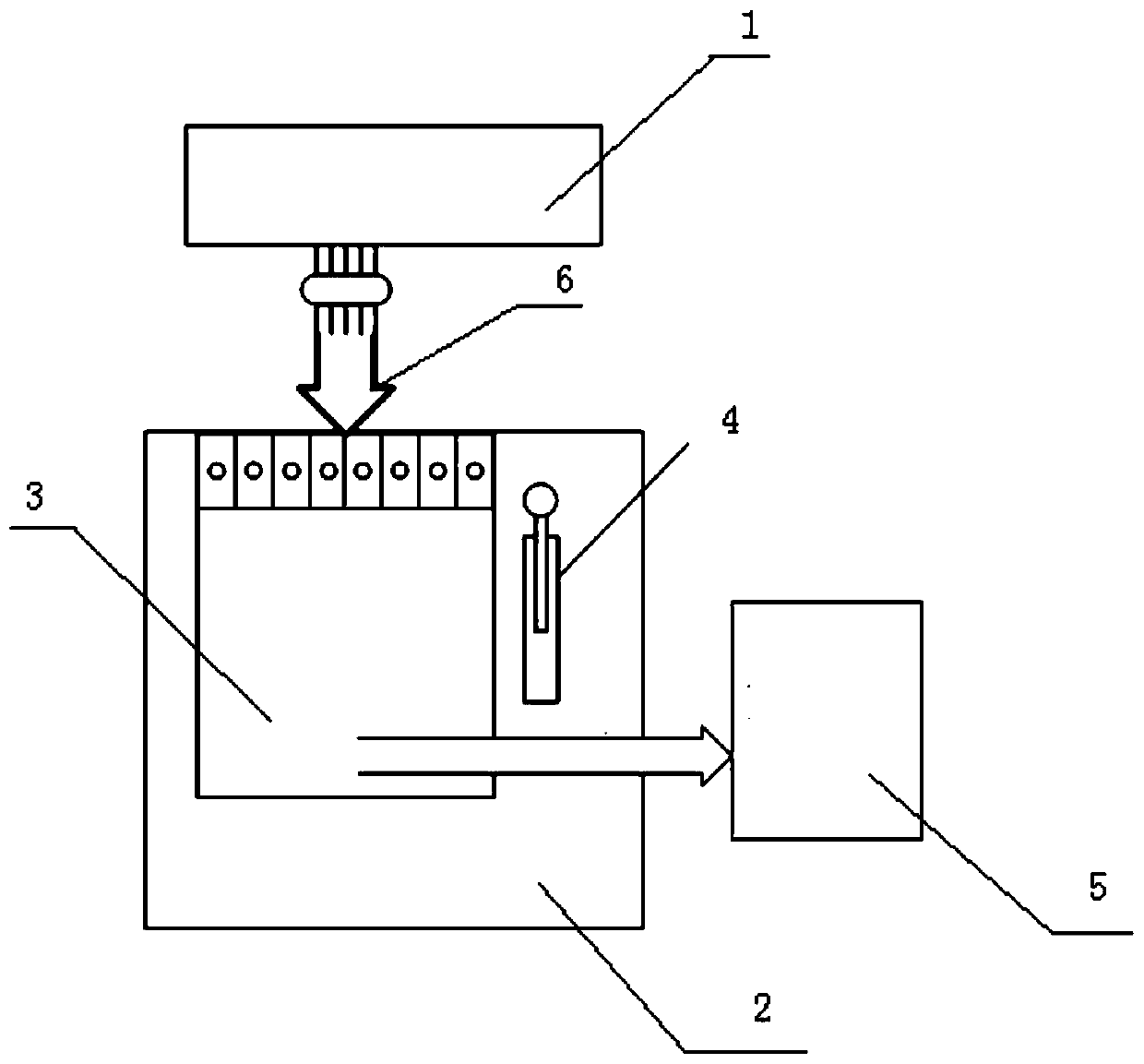

[0036] Such as figure 1 As shown, the embodiment of the present invention provides an intelligent detection system suitable for AC plug-ins, including:

[0037] AC test source 1, the AC test source 1 is used to provide test signals, and can be purchased directly from the market. Its structure itself is not the invention point of the present invention, so it will not be described too much;

[0038] Test bench 2, the test bench 2 is provided with accommodating slots for placing the AC plug-in to be tested, and the test bench is also provided with a first socket 7 containing several strong electric signal input terminals and a first socket 7 containing several weak electric signal output terminals. a second receptacle for the terminal;

[0039] A plurality of signal input cables 6, the number of which is the same as the number of input terminals in the AC plug-in to be tested, one end of each signal input cable is connected with the corresponding output terminal on the described...

Embodiment 2

[0050] An embodiment of the present invention provides an intelligent detection method for an AC plug-in for a terminal, including the following steps:

[0051] (1) Utilize the signal input cable to connect the AC test source with the corresponding strong electric signal input terminal on the test bench, the quantity of the signal input cable is the same as the input terminal quantity in the AC plug-in to be tested; in one embodiment of the present invention In a specific implementation manner, a connection cable is provided between the AC test source and the first socket, and the connection cable includes the same number of signal input cables as the number of input terminals in the AC plug-in to be tested and wrapped in all signal input cables. Insulation on the outside;

[0052] (2) Utilize the signal output cable to connect the data processing unit with the corresponding weak current signal output terminal on the test bench, the quantity of the signal output cable is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com