Test device for radial static pressure gas bearing experiment

A technology of static pressure gas bearing and testing device, which is applied in the direction of mechanical bearing testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

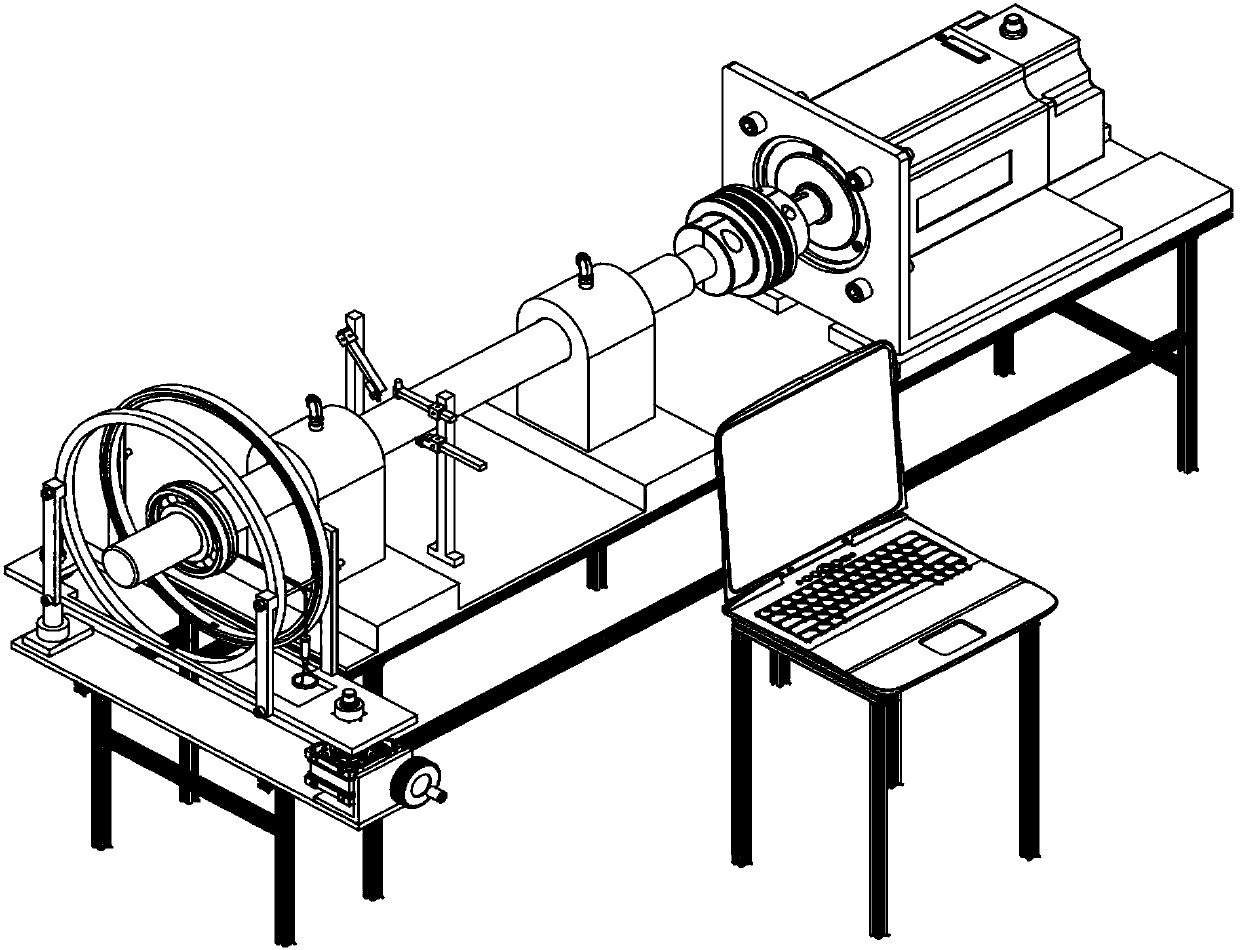

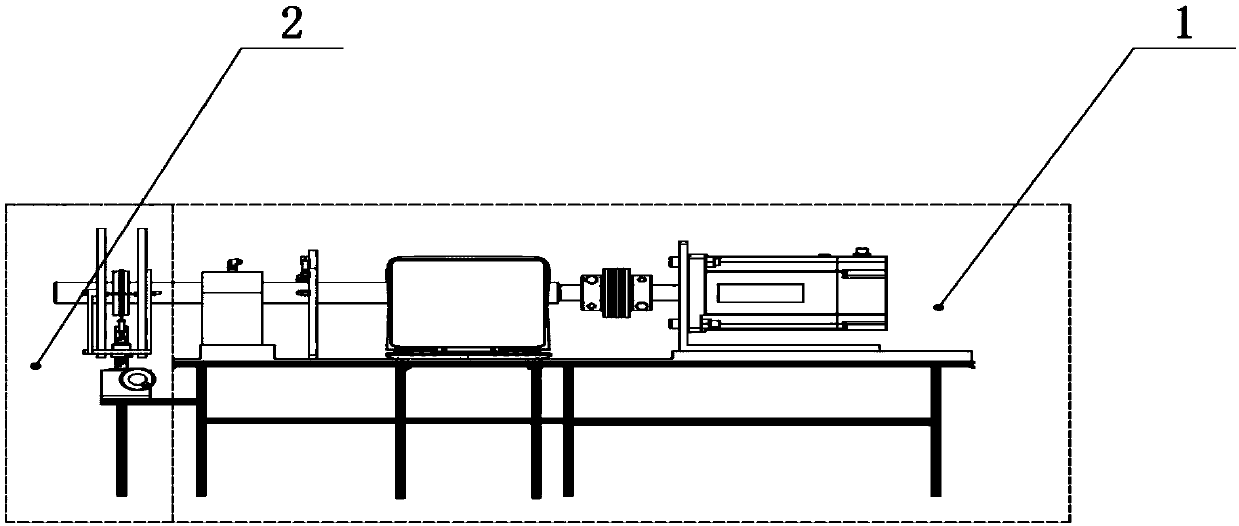

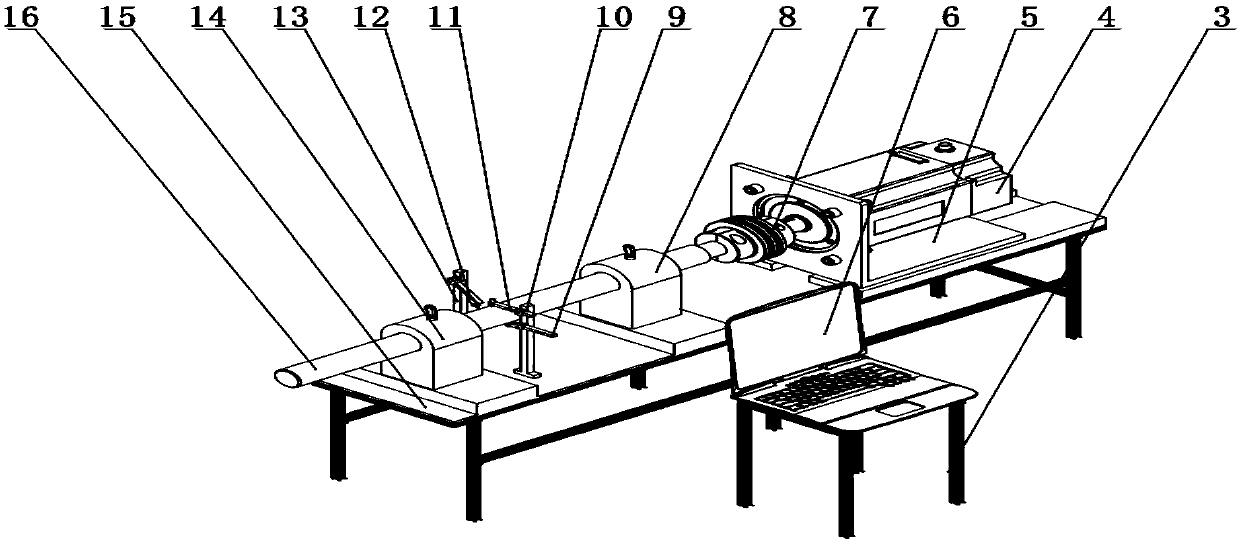

[0015] In order to facilitate researchers in the field to understand and use the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] please see figure 1 and figure 2 , the present invention provides a test bench suitable for performance testing of various radial gas bearings, including a spindle system (1), a loading mechanism (2), a computer table (3), a driving motor (4), and a motor fixing frame (5 ), computer (6), coupling (7), radial static pressure gas bearing a (8), micro-displacement sensor a (9), micro-displacement sensor bracket a (10), micro-displacement sensor b (11), Micro displacement sensor b (12), micro displacement sensor bracket (13), radial static pressure gas bearing b (14), frame (15), main shaft (16), parallel wheel a (17), parallel wheel b (18 ), loading bearing (19), round leather sheath (20), tension rope (21), bearing rod (22), spring dynamometer (23), weight pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com