Air spring stiffness characteristic test device

A technology of air spring and test device, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. The effect of large scope and simple fixture structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

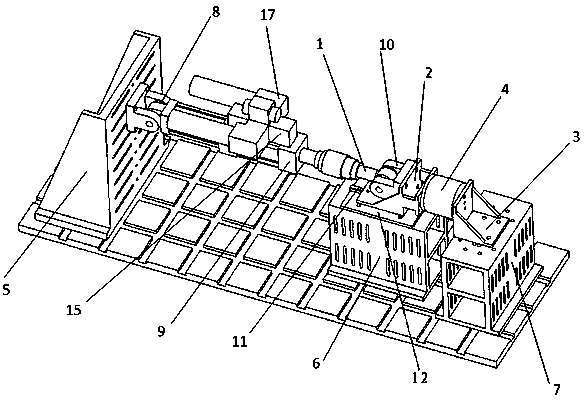

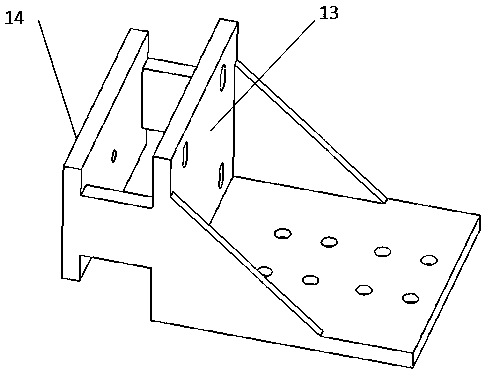

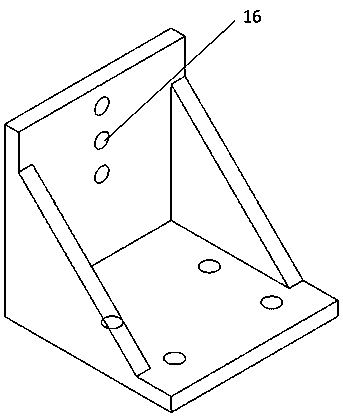

[0011] Such as figure 1 , figure 2 , image 3 As shown, the present invention has a horizontal structure, and the main supporting bodies include a wedge-shaped support 5, a guide support 6, and an air spring support 7, and the bases of the three are fixed on the ground. The base of the joint one 8 is connected with the right side end face of the wedge-shaped support 5, and the height is adjustable, and a rotating pair is connected between the actuator cylinder block 9 and the joint one 8. The actuating head 1 and the joint 2 10 are also connected by a rotating pair. This connection can avoid space interference when the actuating head 1 moves due to over-constraint. The base of the joint 2 10 is fixed on the slide rail gas spring connecting plate 2 by bolts. At the same time, the bottom surface of the gas spring connecting plate 2 of the slide rail is connected with the guide rail 11. The two are sliding pairs, and its main function is to guide and reduce friction. The guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com