Cyclone oil-gas separator and separation method

An oil and gas separator, cyclone technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as oil film splashing, and achieve the effect of low cost, high cost efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

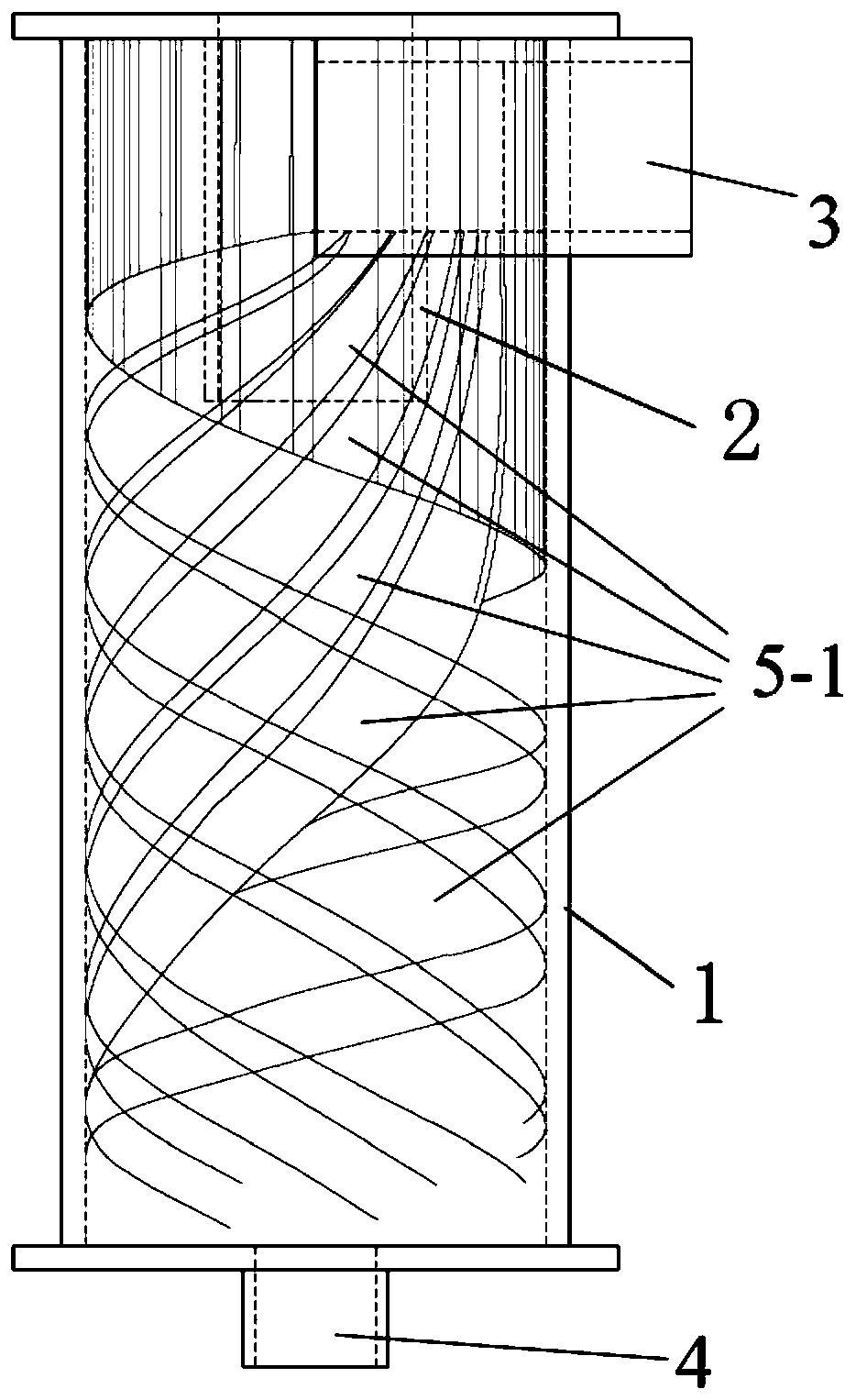

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

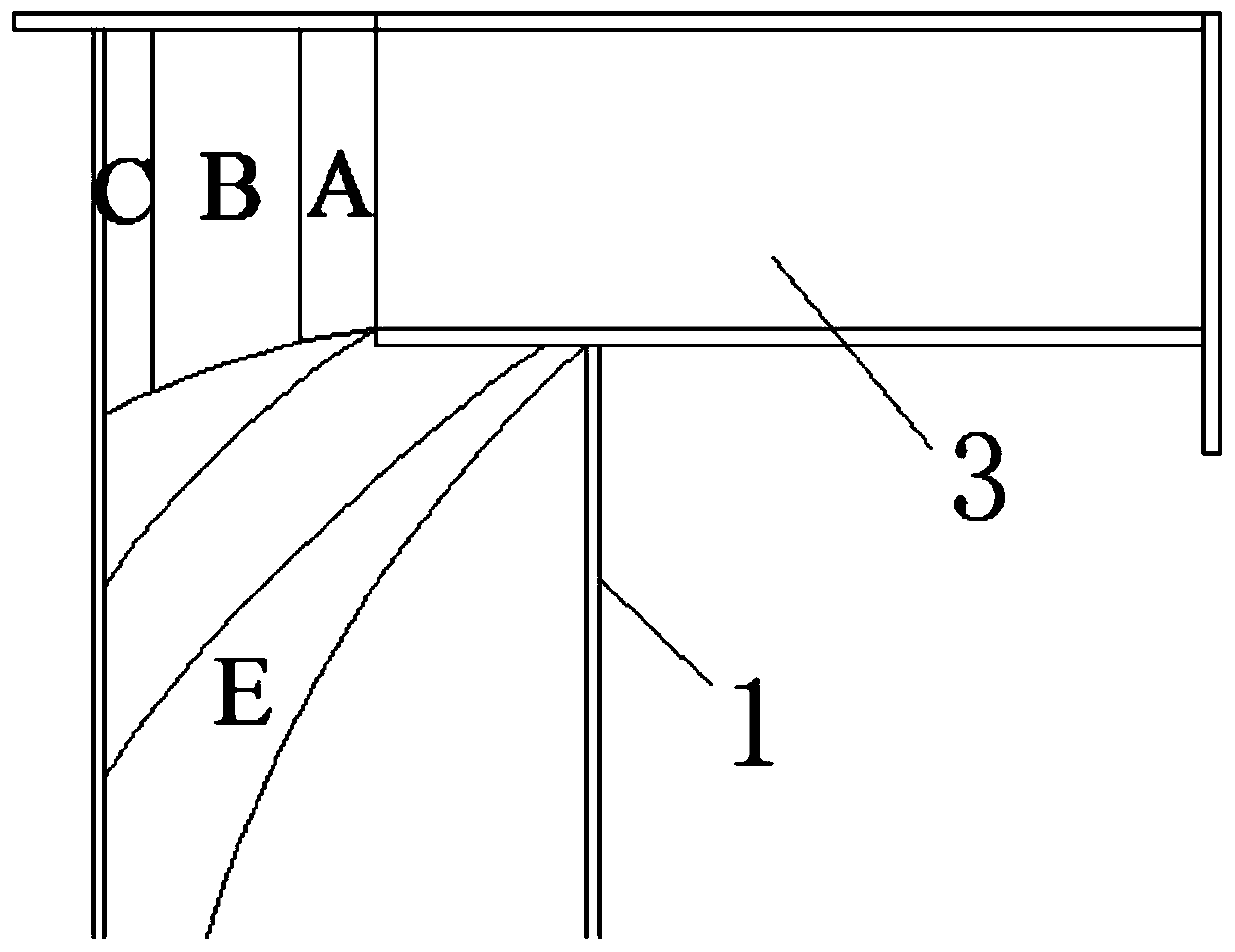

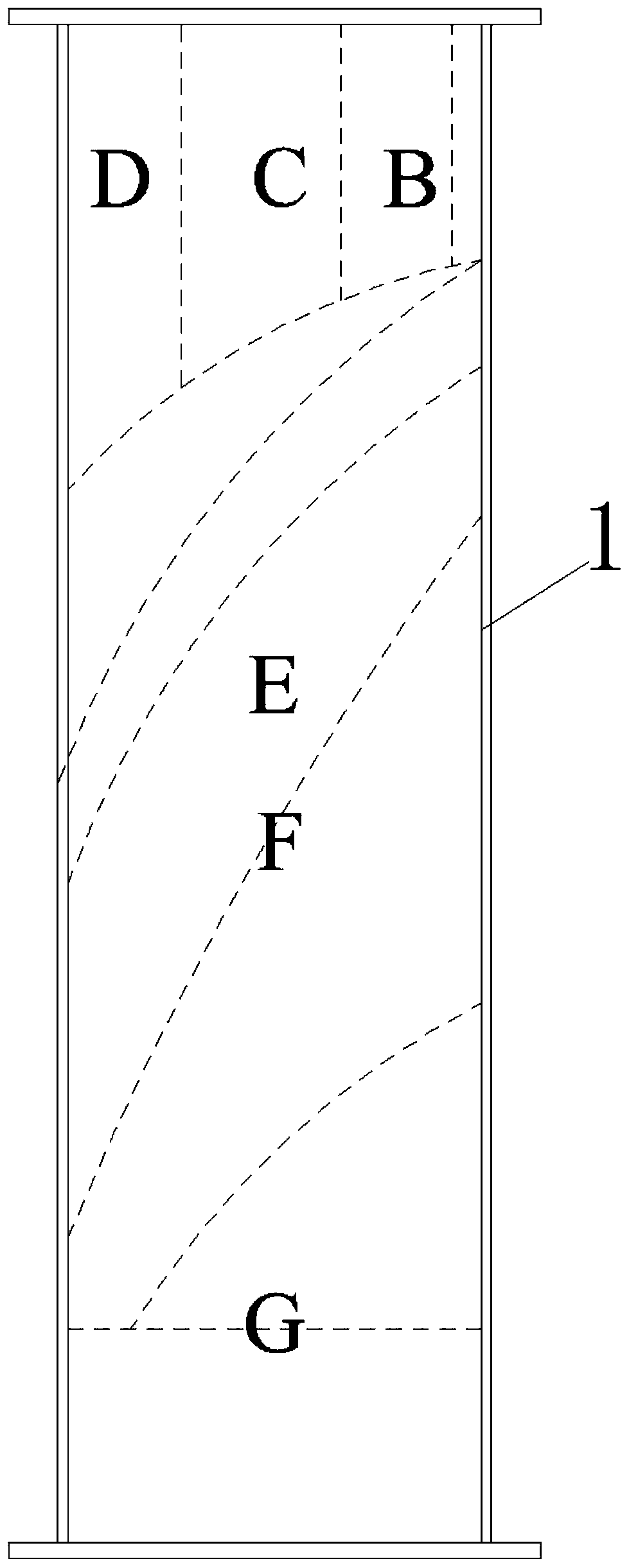

[0037] Design principle of the present invention

[0038] In the previous experiment, a transparent and visible cyclone oil-gas separator was made of plexiglass material, and the oil film distribution on the inner wall surface of the cyclone oil-gas separator was observed and studied. According to the distribution characteristics of the oil film, the inner wall of the outer cylinder can be divided into two parts: the top ring and the middle and lower swirl area. According to the specific liquid film shape and thickness, it can be divided into A, B, C, D, E, F, G seven areas, such as figure 1 , figure 2shown. Among them, G is the complete liquid phase region, and the four regions A, B, C, and D surround the cyclone inner cylinder and the cyclone outer cylinder. The oil-gas mixture in this region has a high oil content, and the oil droplets hit the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com