Remote-control sliding-type pulp distributor

A slip-type, slurry-separating technology, which is applied to mobile frames, supporting machines, shaft linings, etc., can solve the problems of large impact on coating quality, high labor intensity of construction personnel, and long construction period, achieving considerable economic benefits and easy construction. The effect of function expansion and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

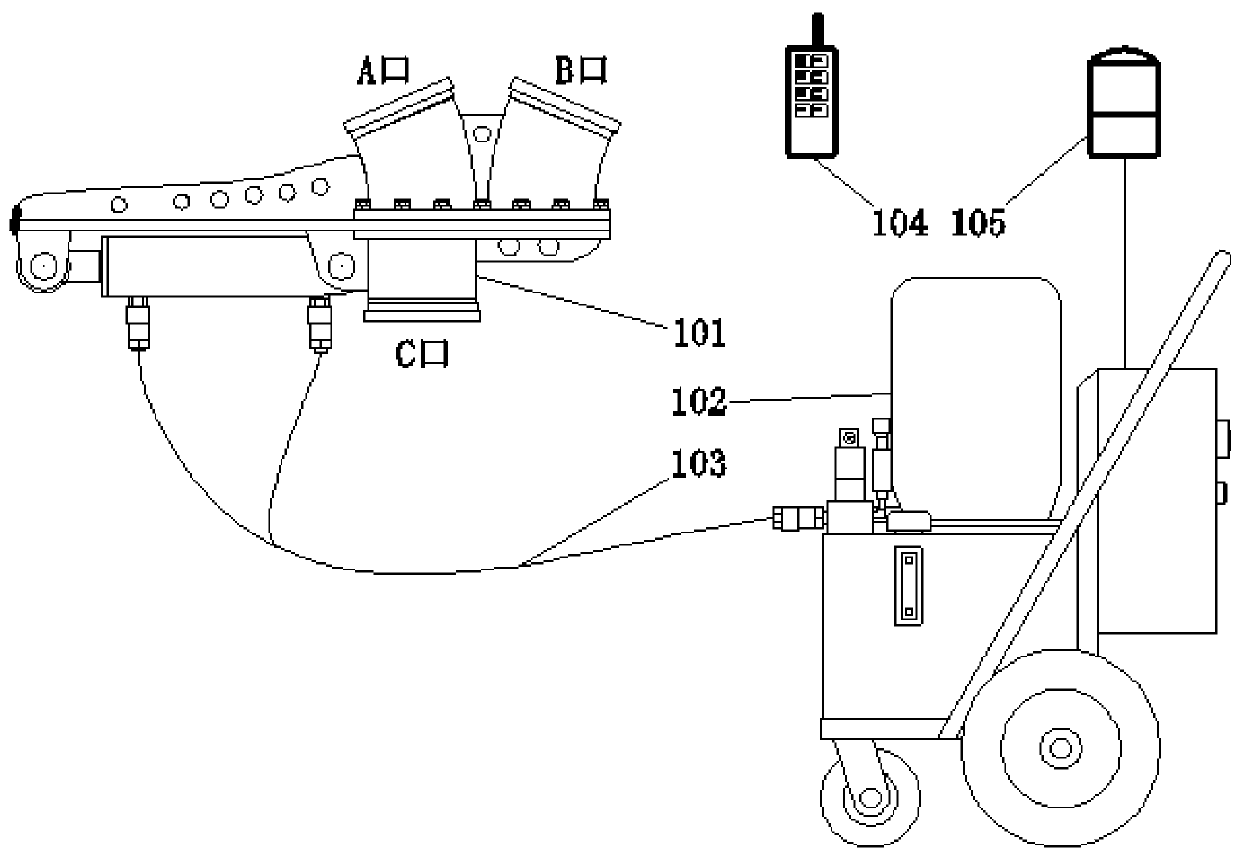

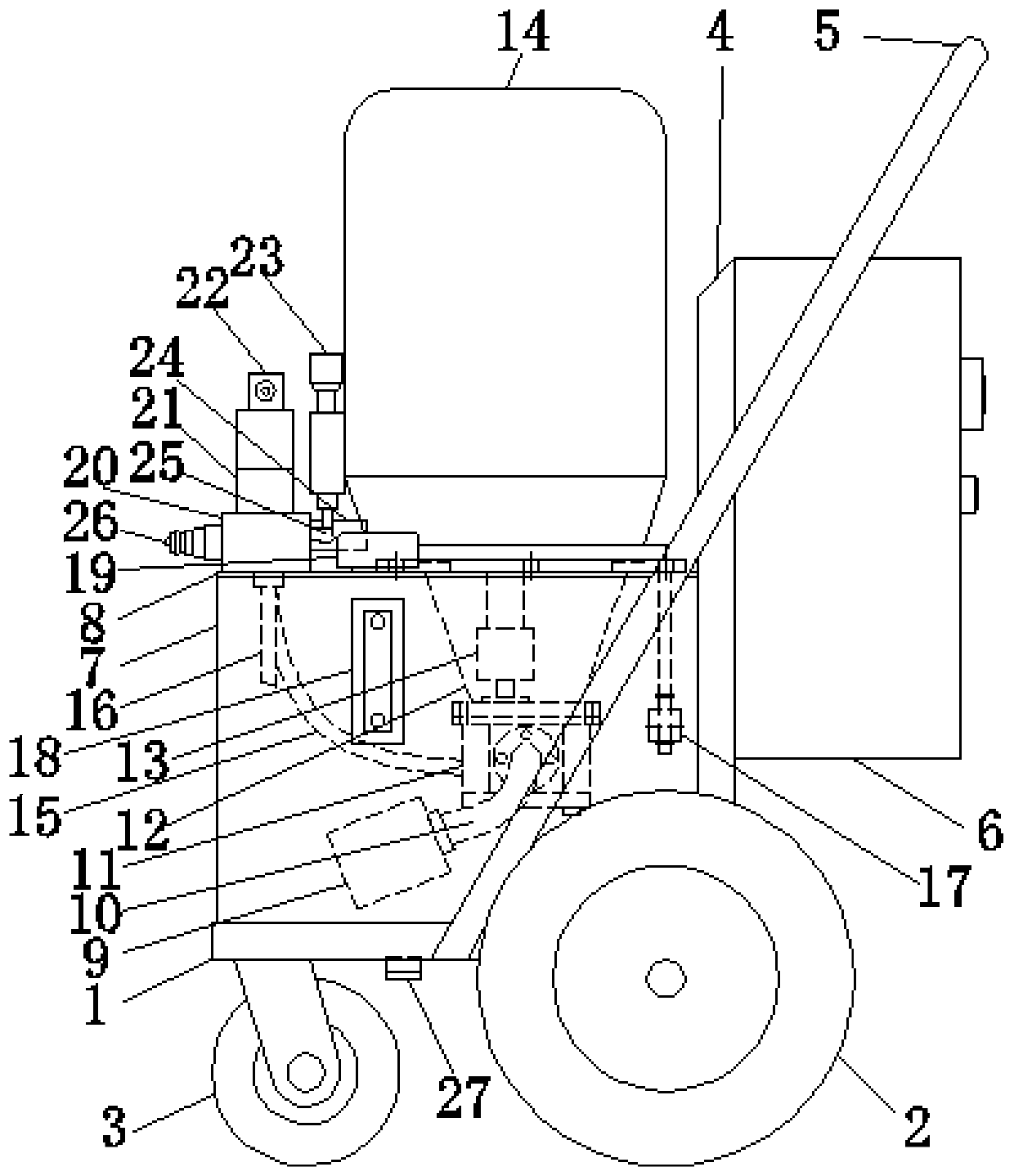

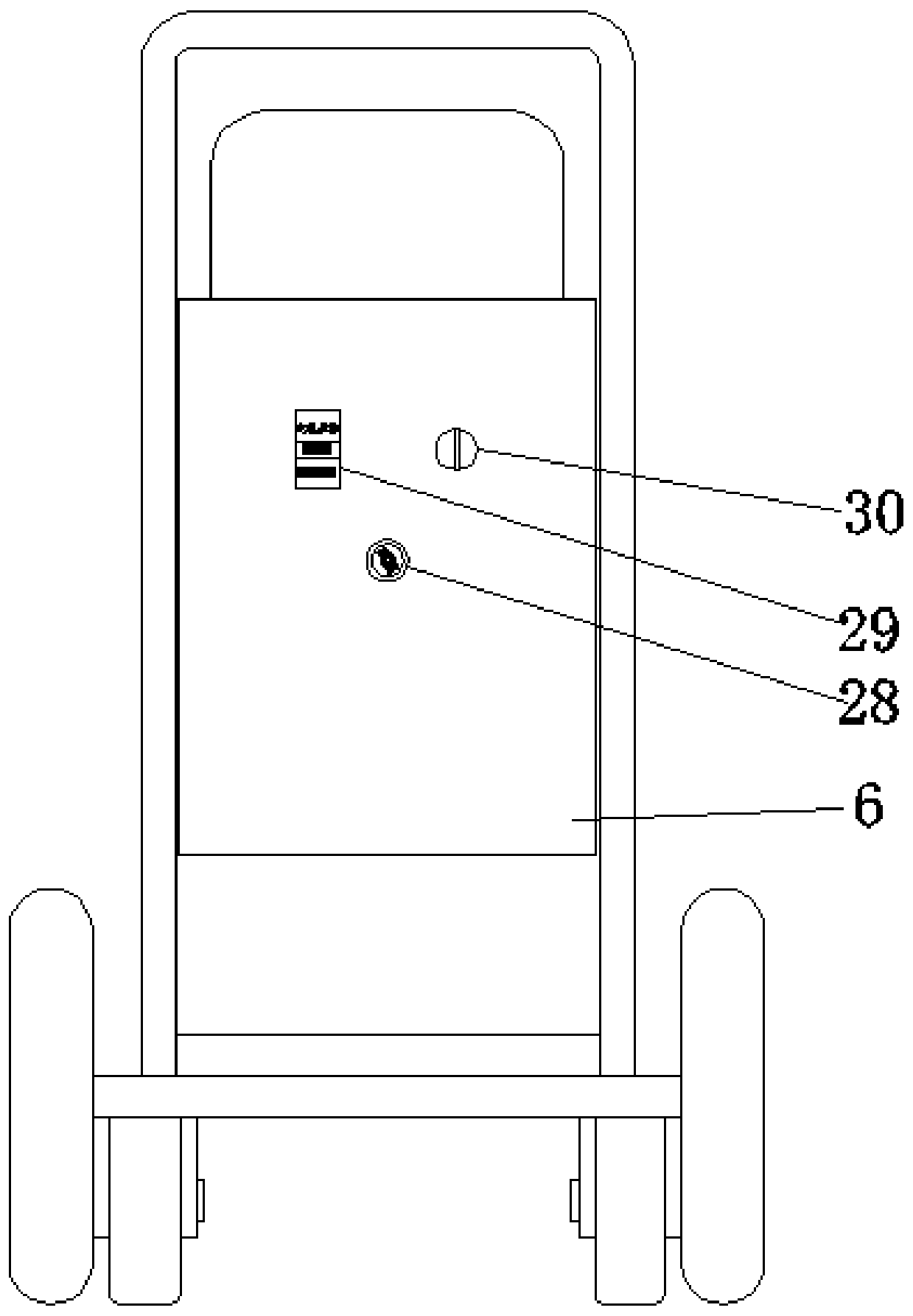

[0033] Such as Figures 1 to 13 As shown, a remote control sliding type separator includes: sliding type separating device 101, mobile remote control pumping station 102, remote controller 104 and sound and light alarm 105; described sliding type separating device 101 and mobile The remote control pump station 102 is connected by a hydraulic oil pipe 103 with a quick connector 26; an audible and visual alarm 105 is arranged outside the mobile remote control pump station 102; the audible and visual alarm 105 is connected to the mobile remote control The pumping stations 102 are electrically connected; the remote control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com