Structural column mold shell and preparation method thereof

A technology for constructing columns and formwork, which is applied in the on-site preparation of building components, building construction, formwork/formwork/work frame, etc., can solve the problems of low formwork strength and low work efficiency, and achieve easy mastery, The effect of reducing work intensity and facilitating implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

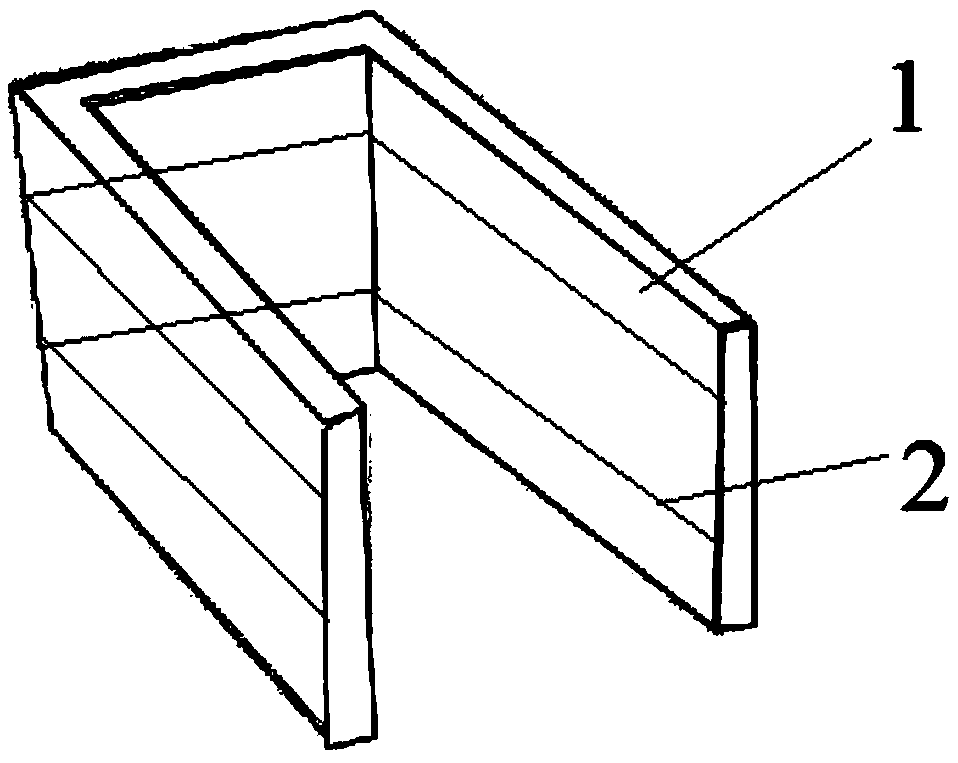

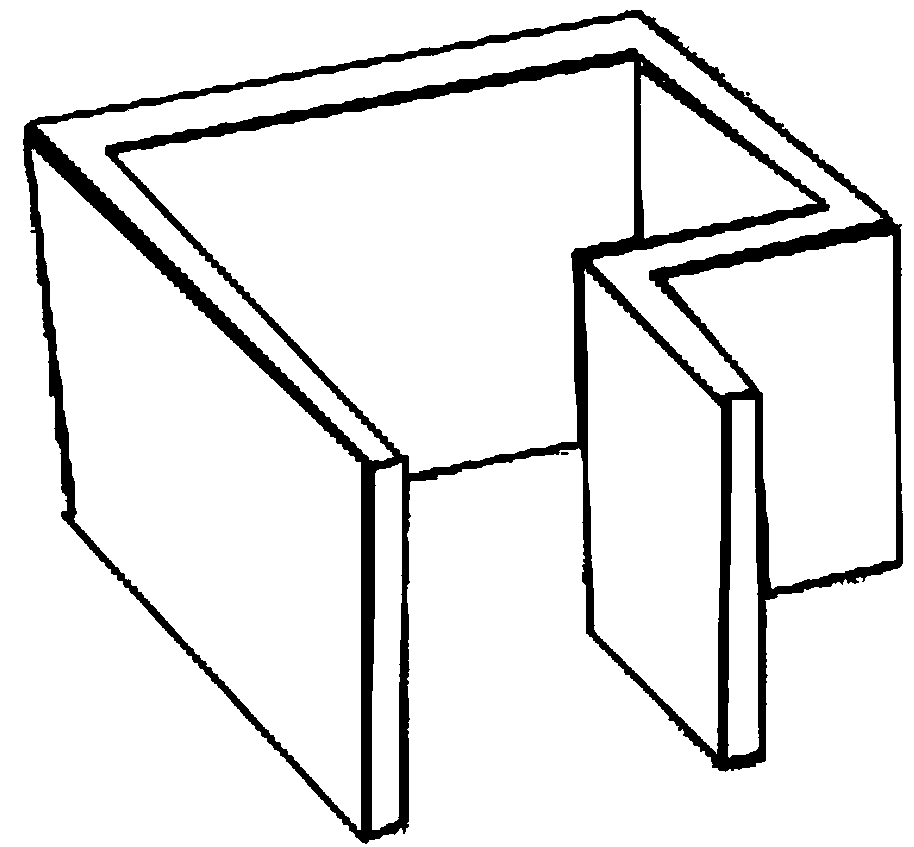

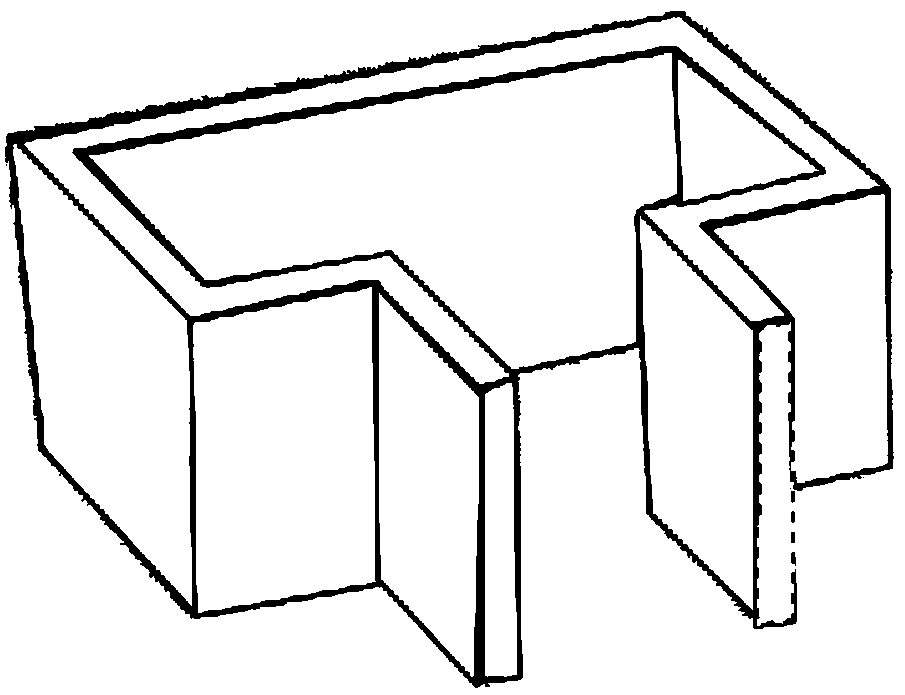

[0025] like Figure 1 to Figure 3 As shown, according to a construction column formwork according to a specific embodiment of the present invention, the formwork is surrounded by a plurality of concrete slabs 1 and forms a cavity. The cavity is "one", "L", "T" and so on. The junction of the concrete slabs 1 is at an angle of 90°. A plurality of concrete slabs are set on the same horizontal plane and are integrally formed. There is an opening on one side of the formwork. The concrete slab is made of multi-layer steel bars 2 and poured concrete. The formwork of " one " font is example, and present embodiment has 2 layers of steel bars. The steel bar adopts Φ5mm steel bar. The thickness of the formwork is 15-20mm, and the formwork is relatively light and thin. After construction, the formwork and the structural column can be better combined into a whole, and the work intensity of the constructor can also be reduced.

[0026] In parts by weight, the raw materials of the concre...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is that the raw materials of the concrete are different. In parts by weight, the raw materials of the concrete include: 50 parts of stone powder, 10 parts of cement, 3 parts of carboxyethyl cellulose, 3 parts of acrylic acid, 3 parts of maleic anhydride, 2 parts of water reducer, 3 parts of salicylic acid , 3 parts of hydroquinone, 4 parts of boric acid and 2 parts of dispersible latex. The water reducer is YZ-1 naphthalene series high-efficiency water reducer.

[0035] In parts by weight, the redispersible latex is mainly made of the following raw materials: 30 parts of EVA rubber powder, 15 parts of azodicarbonamide, 2 parts of sodium oleate, 3 parts of peanut oil and 1 part of anti-caking agent. The anti-caking agent is talcum powder.

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is that the raw materials of the concrete are different. In parts by weight, the raw materials of the concrete include: 100 parts of stone powder, 20 parts of cement, 1 part of carboxyethyl cellulose, 7 parts of acrylic acid, 1 part of maleic anhydride, 7 parts of water reducing agent, and 1 part of salicylic acid , 9 parts of hydroquinone, 1 part of boric acid and 7 parts of dispersible latex. The water reducer is sodium lignosulfonate.

[0038] In parts by weight, the redispersible latex is mainly made of the following raw materials: 50 parts of EVA rubber powder, 6 parts of azodicarbonamide, 6 parts of sodium oleate, 0.5 part of peanut oil and 3 parts of anti-caking agent. The anti-caking agent is kaolin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com