Segmented flexible isolation bag, device and method

A segmented and vibration-isolated technology, applied in protection devices, buildings, infrastructure engineering, etc., can solve the problems of low vibration isolation efficiency, poor vibration isolation effect, and reduced vibration isolation effect, so as to prevent the tank wall from collapsing and improve construction efficiency. High efficiency and high vibration isolation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

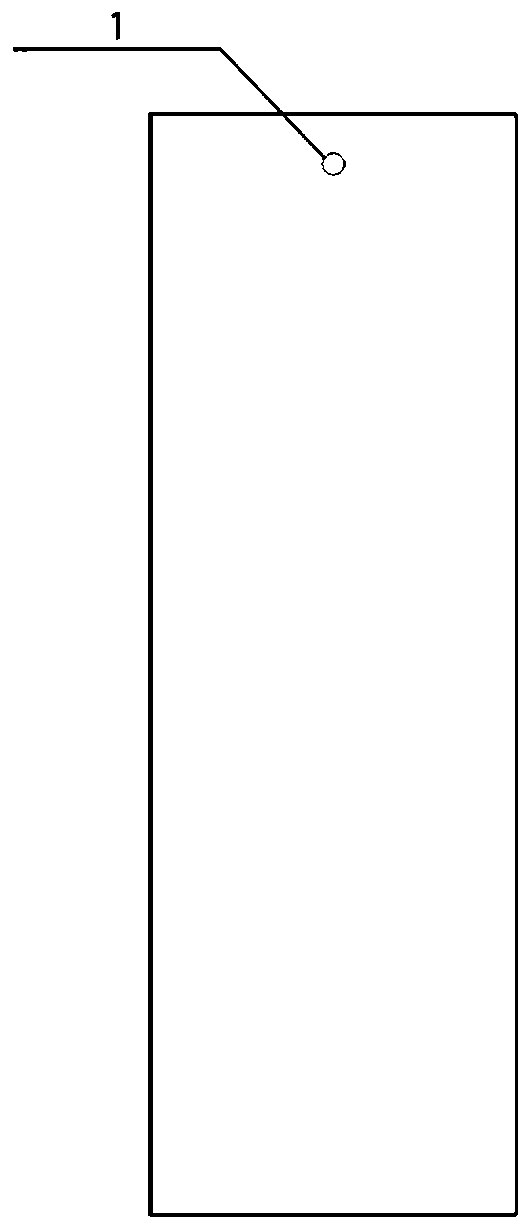

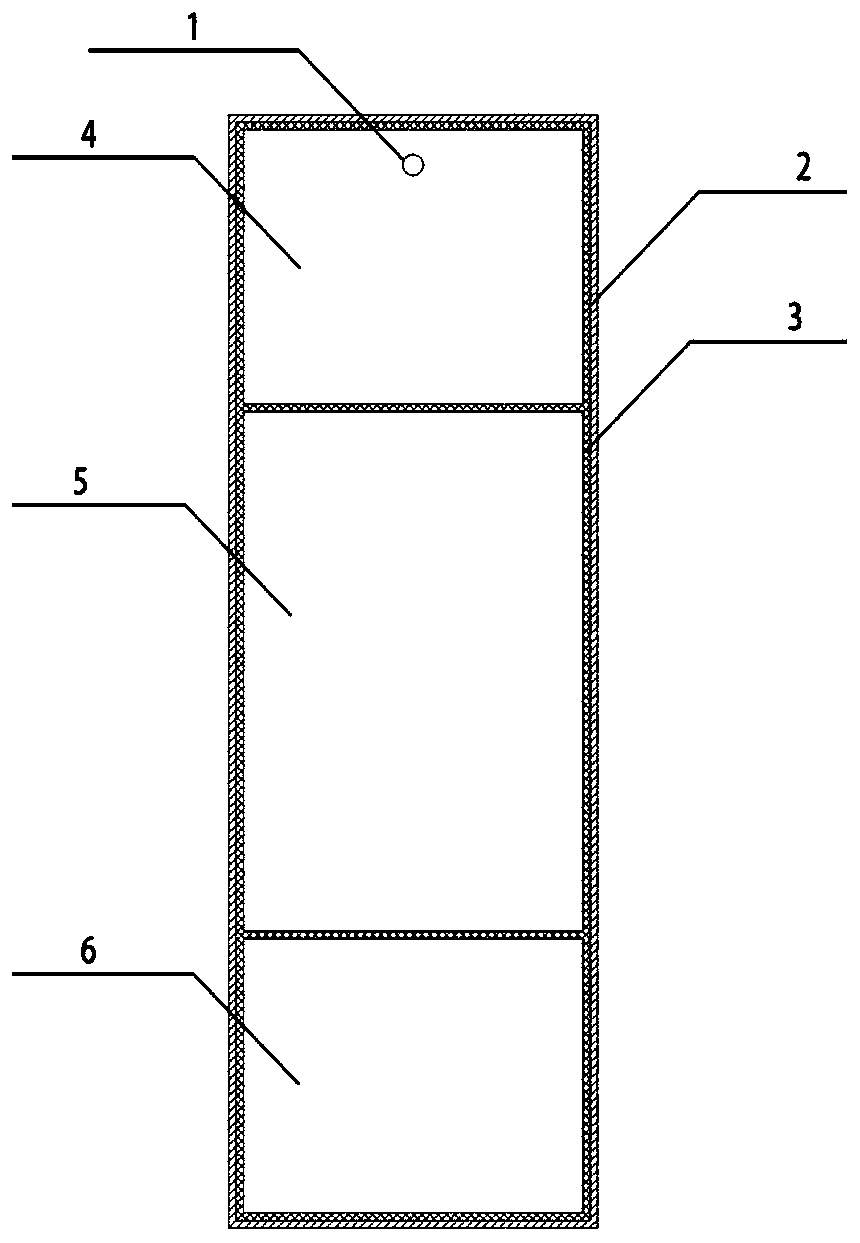

[0051] Example 1, such as Figure 1-3As shown, a segmented flexible vibration isolation bag includes an inner membrane 3, which surrounds and forms a cavity, and the outer coating of the inner membrane 3 is provided with an outer protective layer 2; the cavity is filled with There is a vibration isolation medium; the cavity includes an upper cavity 4, a middle cavity 5 and a lower cavity 6 arranged in isolation from top to bottom; the upper cavity 4 has the same volume as the lower cavity 6, and the middle cavity The volume of the cavity 5 is larger than that of the upper cavity 4 , and the pressure of the vibration-isolation medium in the middle cavity 5 is lower than that of the vibration-isolation medium in the upper cavity 4 and the lower cavity 6 .

[0052] Preferably, both the inner membrane 3 and the outer protective layer 2 are made of flexible materials.

[0053] Specifically, the inner membrane 3 is made of a flexible membrane-like material with certain elasticity, ...

Embodiment 2

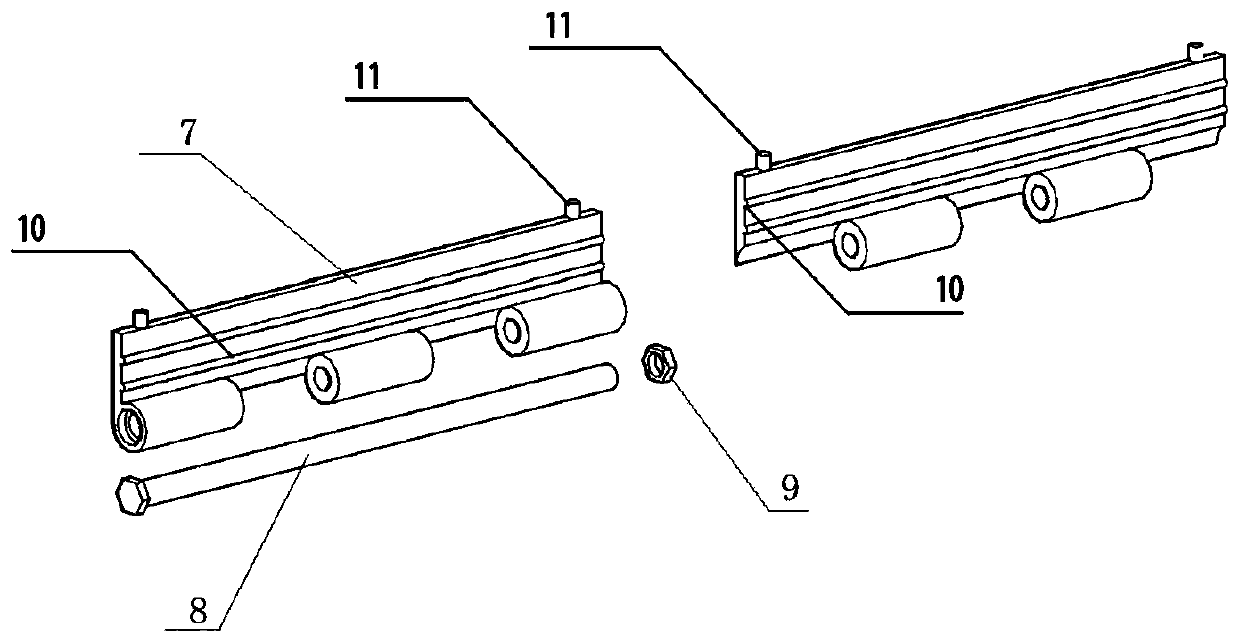

[0058] Example 2, such as Figure 3-7 As shown, a segmented flexible vibration isolation device utilizes a segmented flexible vibration isolation bag, and also includes a guide device and a board device, the guide device is arranged under the segmented flexible vibration isolation bag, and the guide device is used for Guide the segmented flexible vibration isolation bag into the vibration isolation groove or directly into the ground;

[0059] The board insertion device is arranged above the guide device, and the board board device is used to drive the guide device.

[0060] Preferably, the guide device includes two clips 7 that are rotatably connected, and the opposite sides of the two clips 7 are respectively provided with engaging teeth 10, and the upper end surfaces of the clips 7 are respectively provided with connection points 11, and the connection Point 11 is used to connect the plugboard device.

[0061] Preferably, the bottom ends of the two clips 7 are respectively...

Embodiment 3

[0066] Example 3, such as Figure 3-7 As shown, a segmented flexible vibration isolation method includes the following steps:

[0067] The length of the vibration isolation groove is determined according to the scope of the dynamic compaction work area and the protection area, and generally the two sides should exceed the length of the protection area; the depth of the vibration isolation groove should be determined according to the size of the impact energy of the dynamic compaction.

[0068] Step 1) Clear and level the construction site, and determine the reasonable embedding position of the vibration isolation device between the dynamic compaction work area and the protection area according to the construction site conditions and vibration control requirements;

[0069] Step 2) Determine the depth and length of the vibration isolation groove according to the vibration size of the construction site and the scope of the protection zone;

[0070] Step 3) After protecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com