Improved foaming particle, molded body and production process of improved foaming particle

A technology of foamed particles and production process, which is applied in the direction of coating, etc., can solve the problems of difficult to further improve the cushioning performance and heavy weight, and achieve the effects of easy product automation, high molding efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

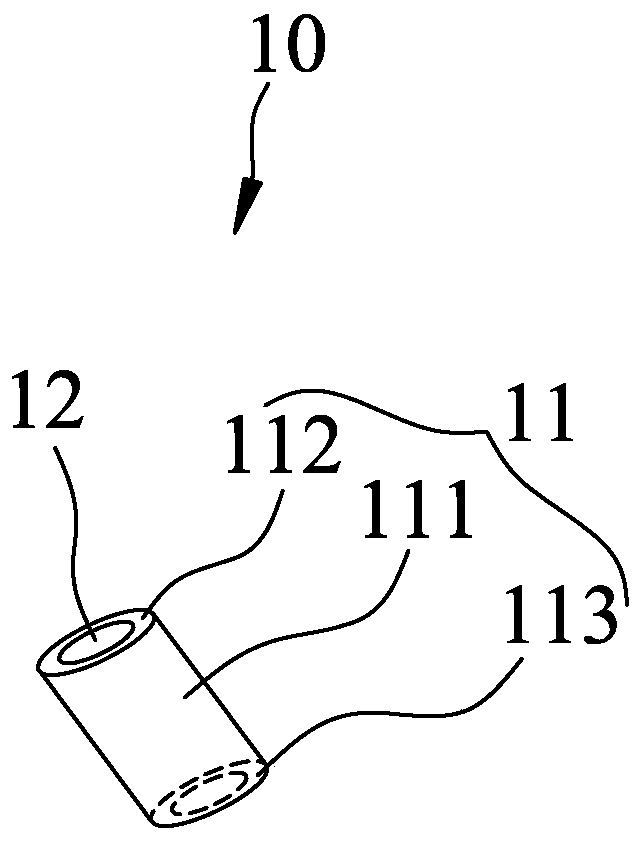

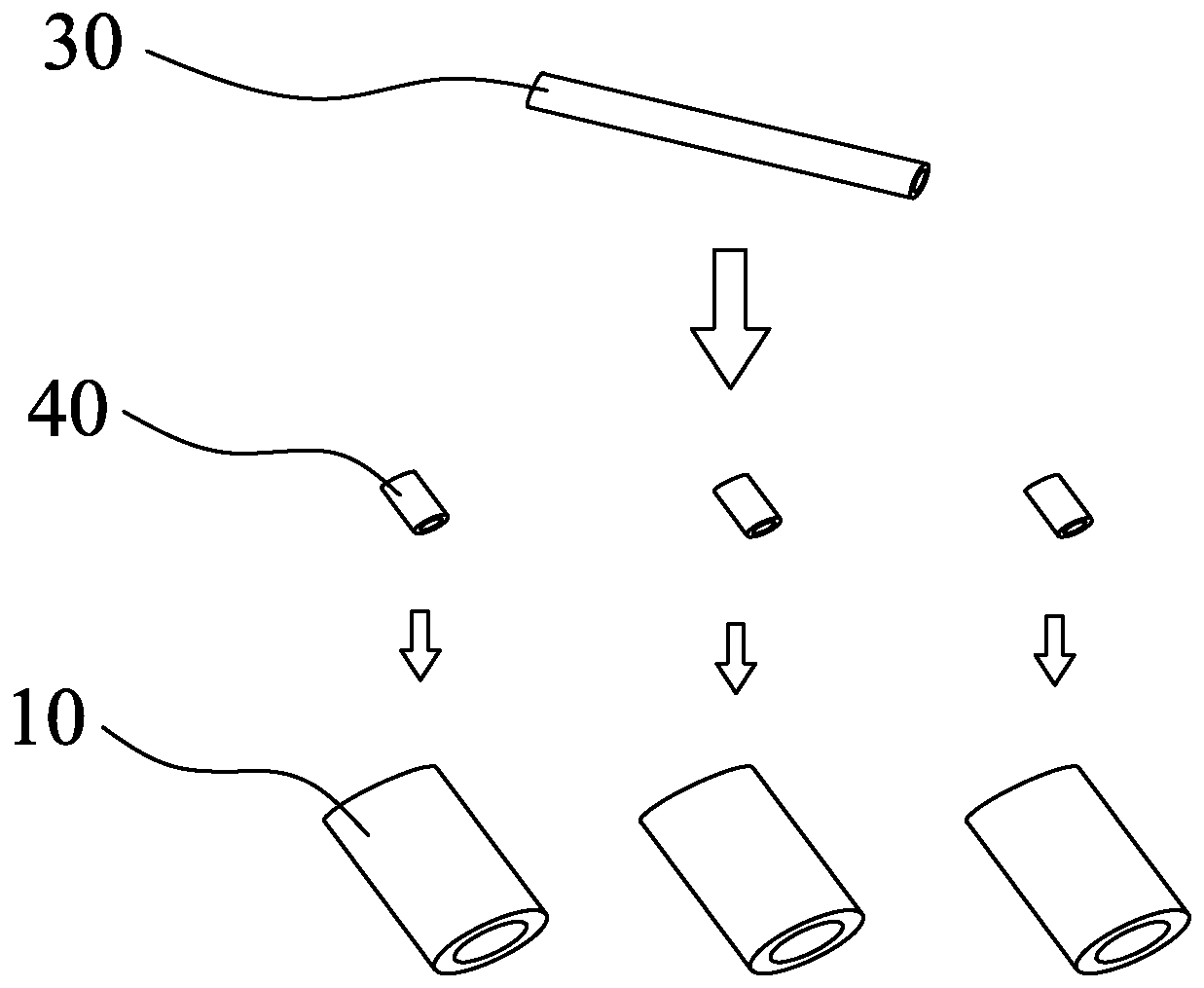

[0025] Such as figure 1 As shown, an improved expanded particle 10 related to the present invention includes a cylindrical elastic body 11, and the cylindrical elastic body 11 is formed with a through hole 12 in the middle position, and the cylindrical elastic body 11 is extruded The shaped cylindrical particles 40 with holes are made by foam molding.

[0026] Wherein, the shape of the cylindrical elastic body 11 is a cylinder composed of a cylindrical side surface 111 , an upper bottom surface 112 and a lower bottom surface 113 , and the through hole 12 is an upper and lower through hole extending along the central axis.

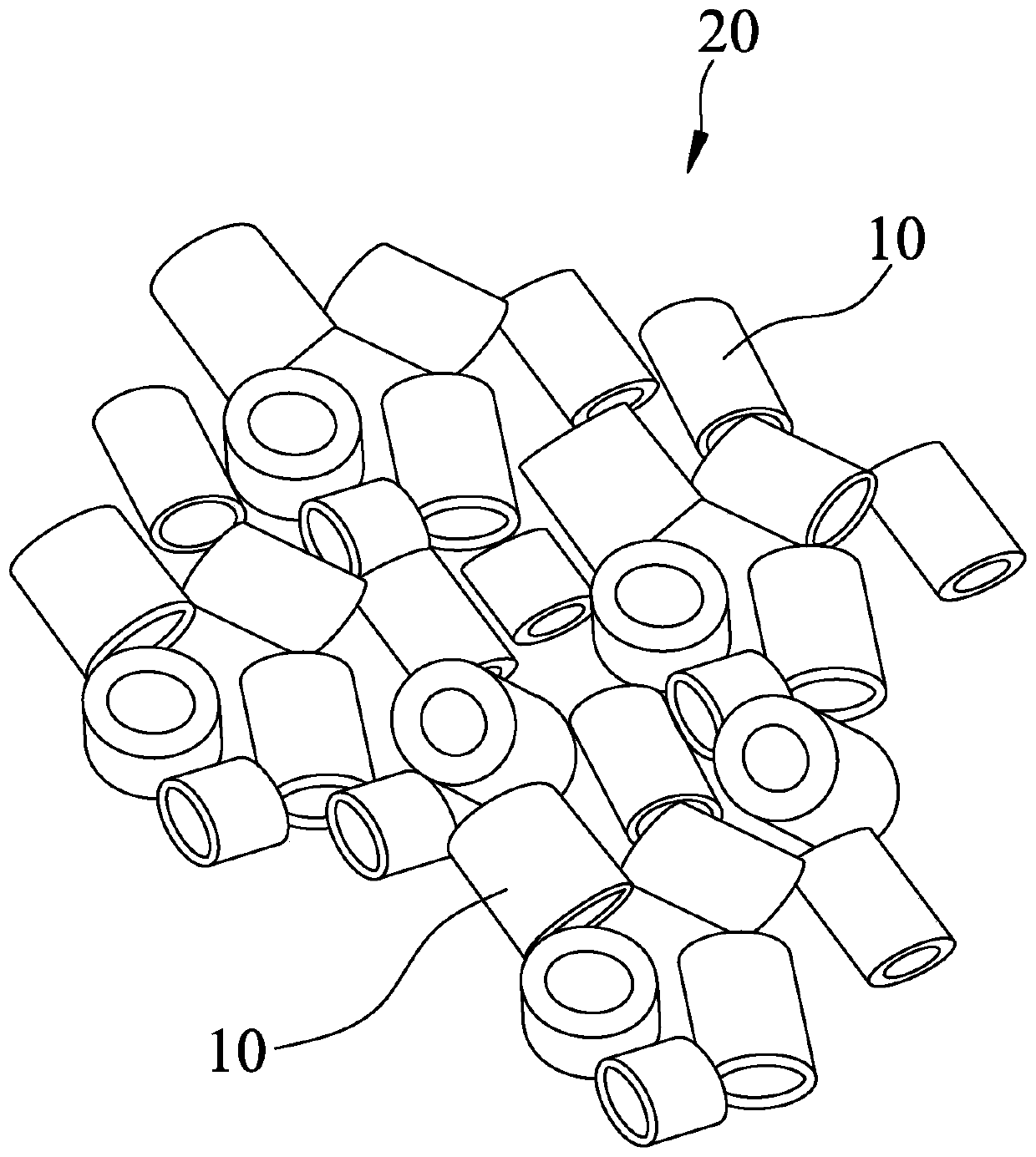

[0027] Such as figure 2 As shown, an improved foam molding 20 related to the present invention includes several cylindrical elastic bodies 11 and an adhesive layer between adjacent cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com