Drive system for a rail vehicle

A drive system and rail vehicle technology, applied in the field of rail vehicles, can solve problems such as expensive, and achieve the effects of reducing requirements, reducing costs, and reducing leakage inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

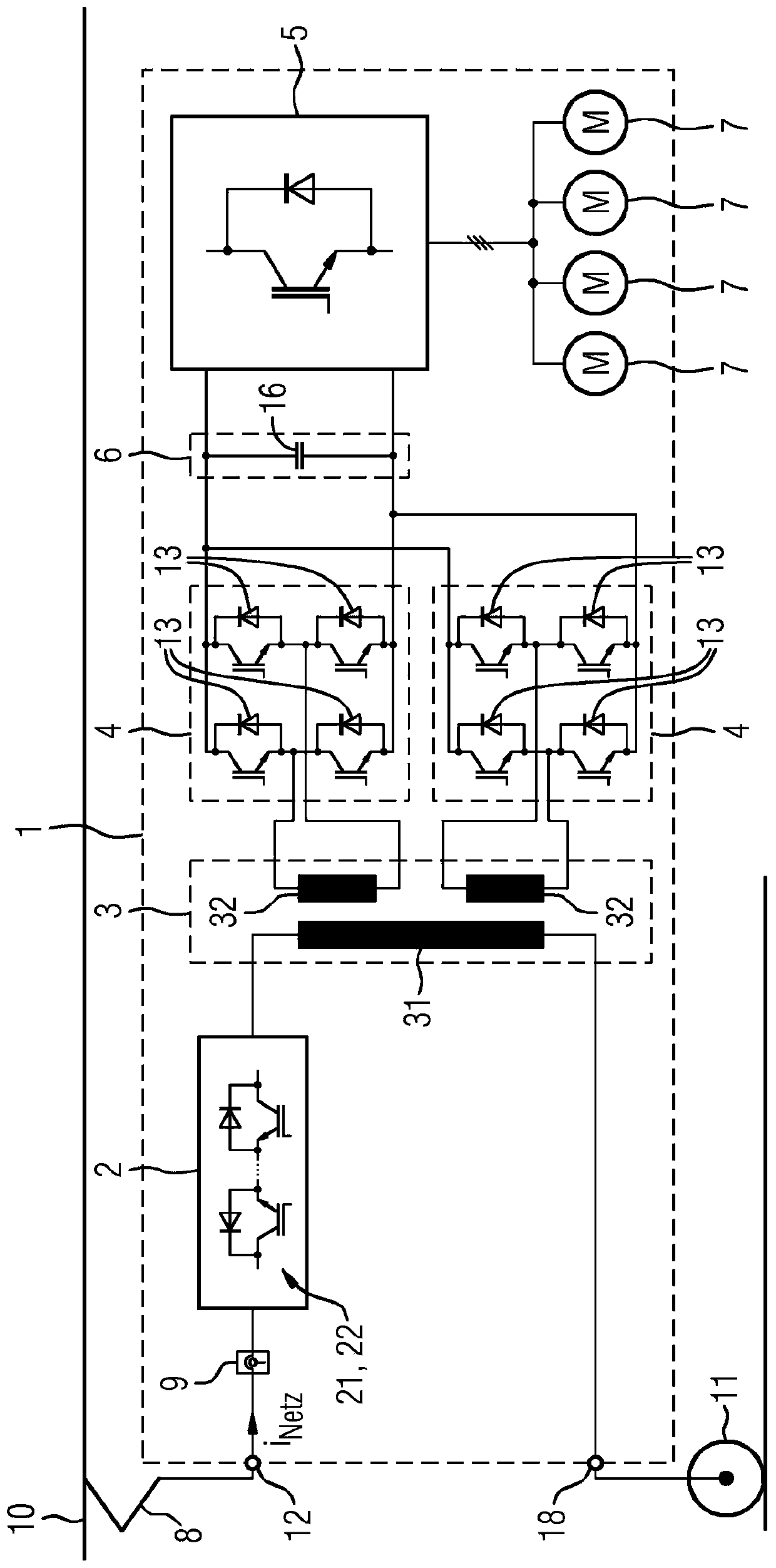

[0040] figure 1 A drive system 1 of a rail vehicle is shown. The drive system has a grid connection 12 for connection to a slip feeder 10 . As an alternative to the contact rail 10 , it is also possible to supply the vehicle with the aid of a contact rail. The current collector 8 makes contact with the contact rail 10 or the busbar. The grid connection 12 is connected to the primary winding 31 of the transformer 3 . A main switch 2 is arranged between the transformer 3 and the grid connection 12 , which makes it possible to interrupt the current flow, in particular during a short circuit in a rail vehicle. In order to detect undesirably or unacceptably high currents, it has proven to be advantageous to provide a current transformer 9 in the circuit. In order to close the circuit via the primary winding of the transformer, the primary winding is also connected to the wheel and the guide rail via the ground connection 18 .

[0041] The secondary winding 32 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com