Camera assembly, electronic equipment and control method of camera assembly

A technology for a camera assembly and an imaging assembly, applied in the field of photography, can solve the problems of increasing the cost of the camera, and the structure is not integrated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

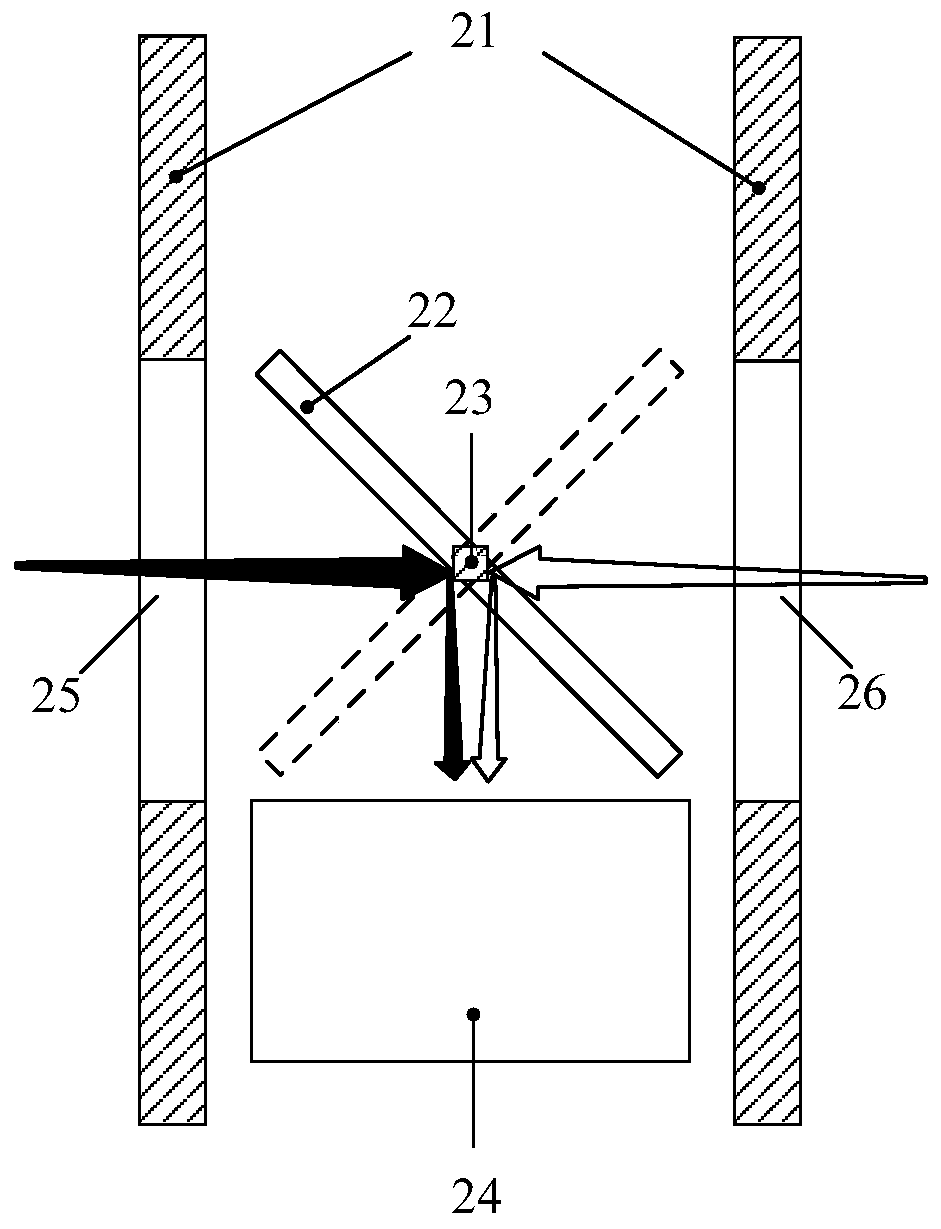

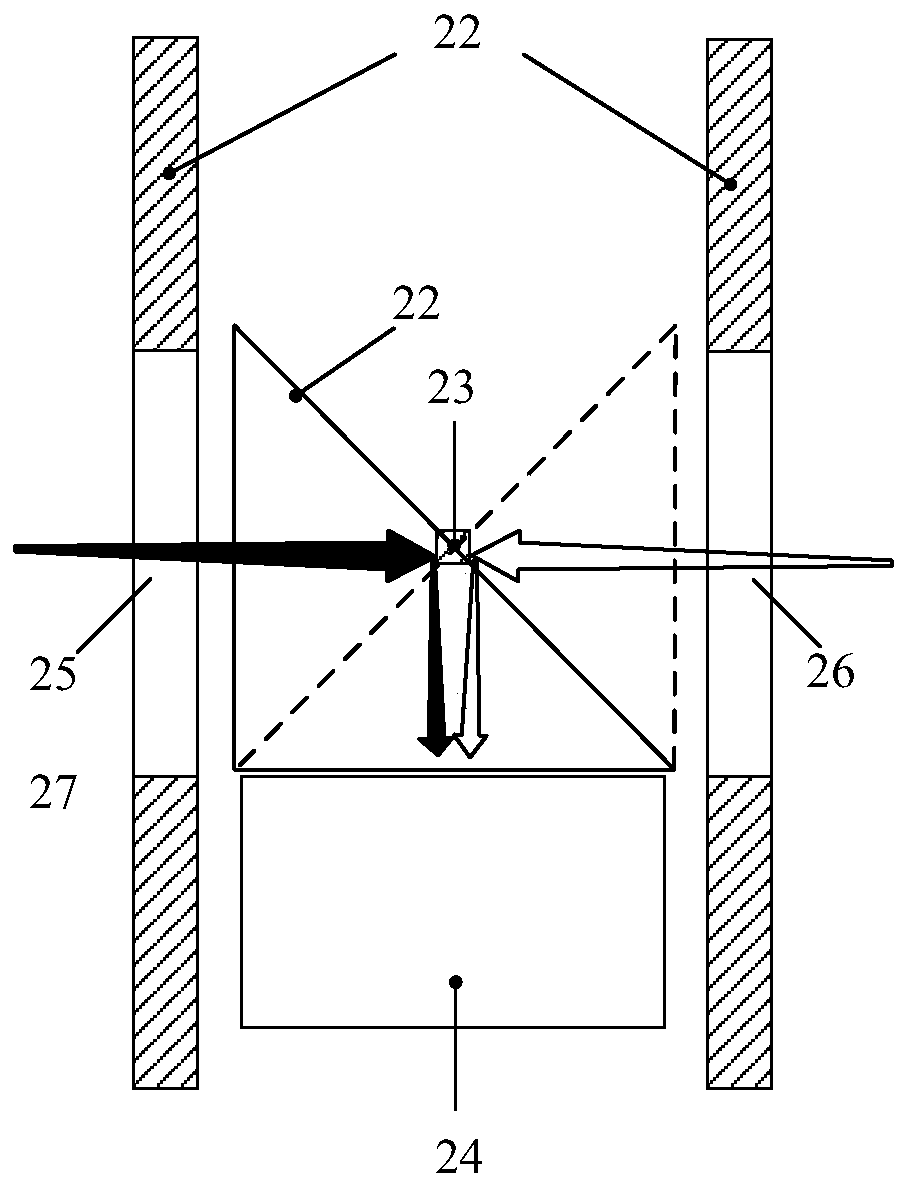

[0020] like figure 2 As shown, the camera assembly includes: a housing 21, a reflection assembly 22, a driving assembly 23 and an imaging assembly 24;

[0021] The casing 21 is provided with a first light-transmitting component 25 and a second light-transmitting component 26 facing oppositely and center-aligned; the drive component 23 drives the reflective component 22 to rotate around the rotation axis, so that the reflective component 22 switch between the first position and the second position;

[0022] The reflective component 22 is in the first position, and the reflective surface of the reflective component 22 reflects the first ambient light passing through the first light-transmitting component 25 to the imaging component 24;

[0023] The reflective component 22 is in the second position, and the reflective surface of the reflective component 22 reflects the second ambient light passing through the second light-transmitting component 26 to the imaging component 24 . ...

Embodiment 2

[0075] An embodiment of the present application also provides a method for controlling a camera assembly, where the camera assembly includes: a housing, a reflection assembly, a driving assembly, and an imaging assembly;

[0076] The casing is provided with a first light-transmitting component and a second light-transmitting component facing opposite and aligned in the center; the driving component drives the reflecting component to rotate around the rotation axis, so that the reflecting component is in the first position and the second light-transmitting component Switch between locations;

[0077] The methods include:

[0078] controlling the reflective component to be in the first position, so that the reflective surface of the reflective component reflects the first ambient light passing through the first light-transmitting component to the imaging component;

[0079] Alternatively, the reflective component is controlled to be at the second position, so that the reflectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com