Linear motor physical precision compensation control system and method

A linear motor, compensation control technology, applied in control system, AC motor control, motor parameter estimation/correction, etc., can solve the problem of physical position deviation, poor physical accuracy, and deviation between the feedback data of the grating scale and the actual position and other issues to achieve precision optimization and improve the effect of displacement control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

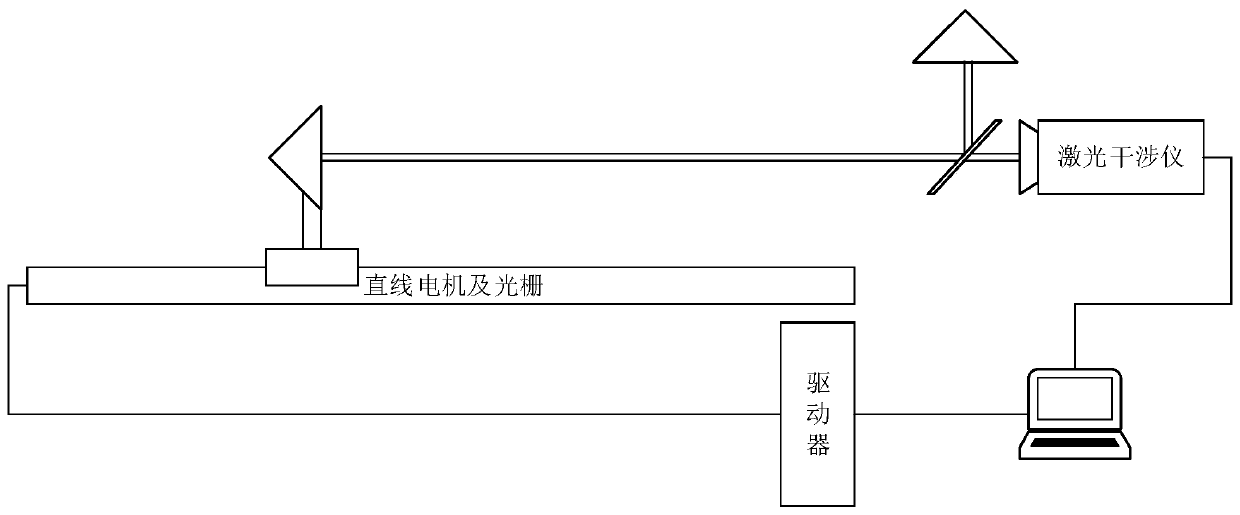

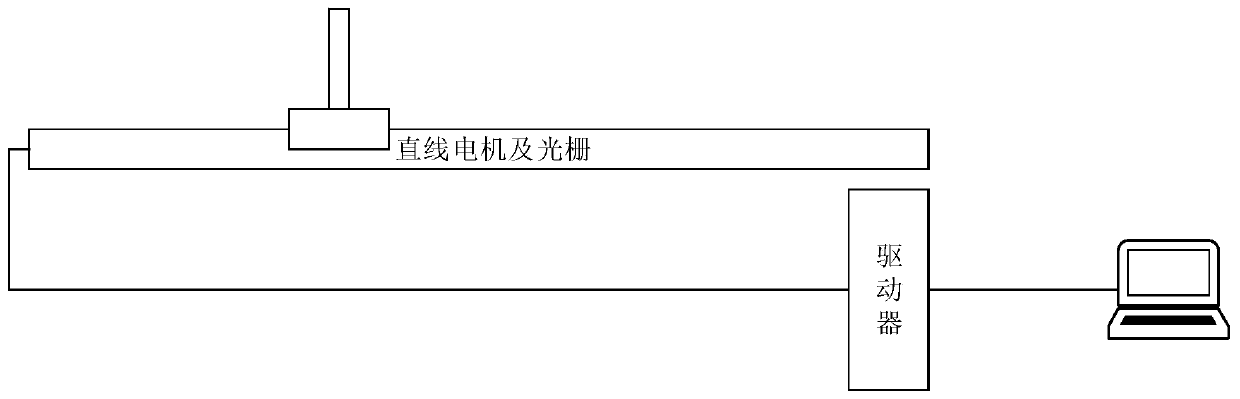

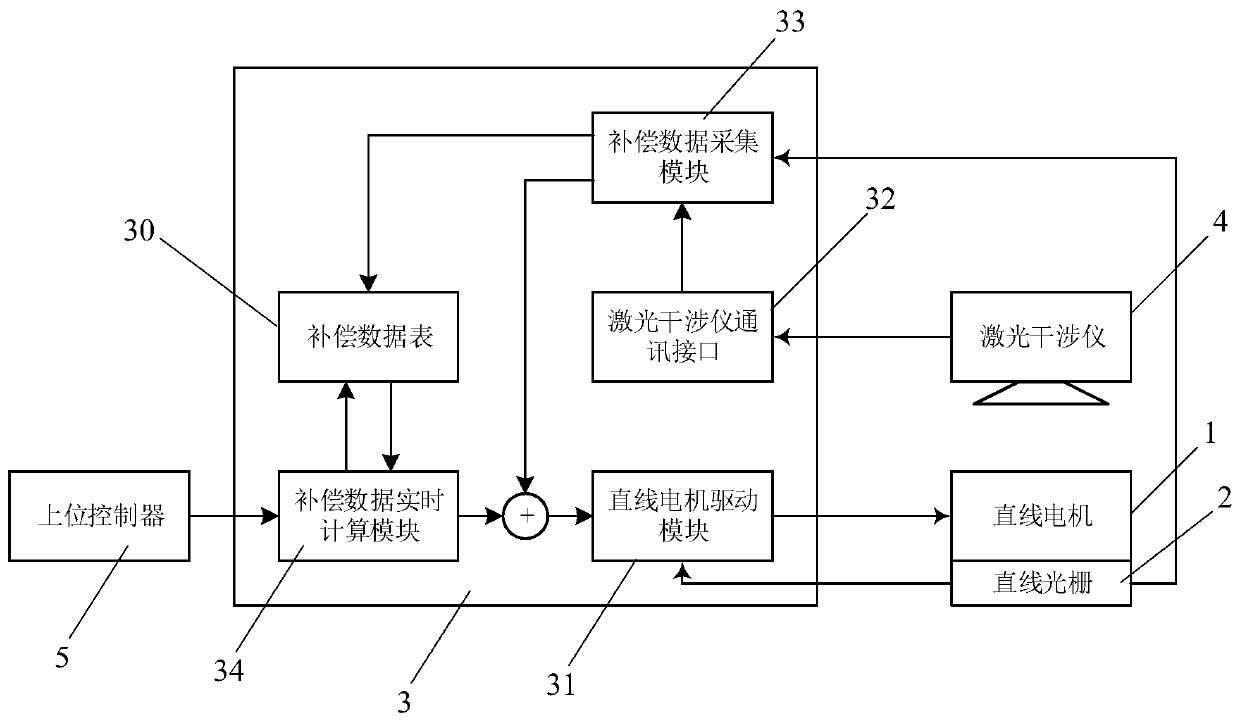

[0024] The invention discloses a linear motor physical precision compensation control system, which combines Figure 1 to Figure 3 As shown, it includes:

[0025] linear motor 1;

[0026] a linear grating ruler 2, used to collect the linear displacement of the linear motor 1;

[0027] Main control unit 3, the linear motor 1 and the linear grating ruler 2 are respectively electrically connected to the main control unit 3, the main control unit 3 is preset with a compensation data table 30, and the moving track of the linear motor 1 is preset There are multiple collection points, and the main control unit 3 is used to execute:

[0028] During the calibration learning process, when the linear motor 1 moves to each collection point, the position data collected by the linear grating scale 2 is fed back to the main control unit 3 and stored in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com