Balanced audio socket automatic assembly machine

An audio socket and balanced technology, which is applied in the field of balanced audio socket automatic assembly machines, can solve the problems that quality and output are easily affected by workers' working conditions, high labor costs, and low production efficiency, so as to reduce manual interference and rely on The effect of low degree and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

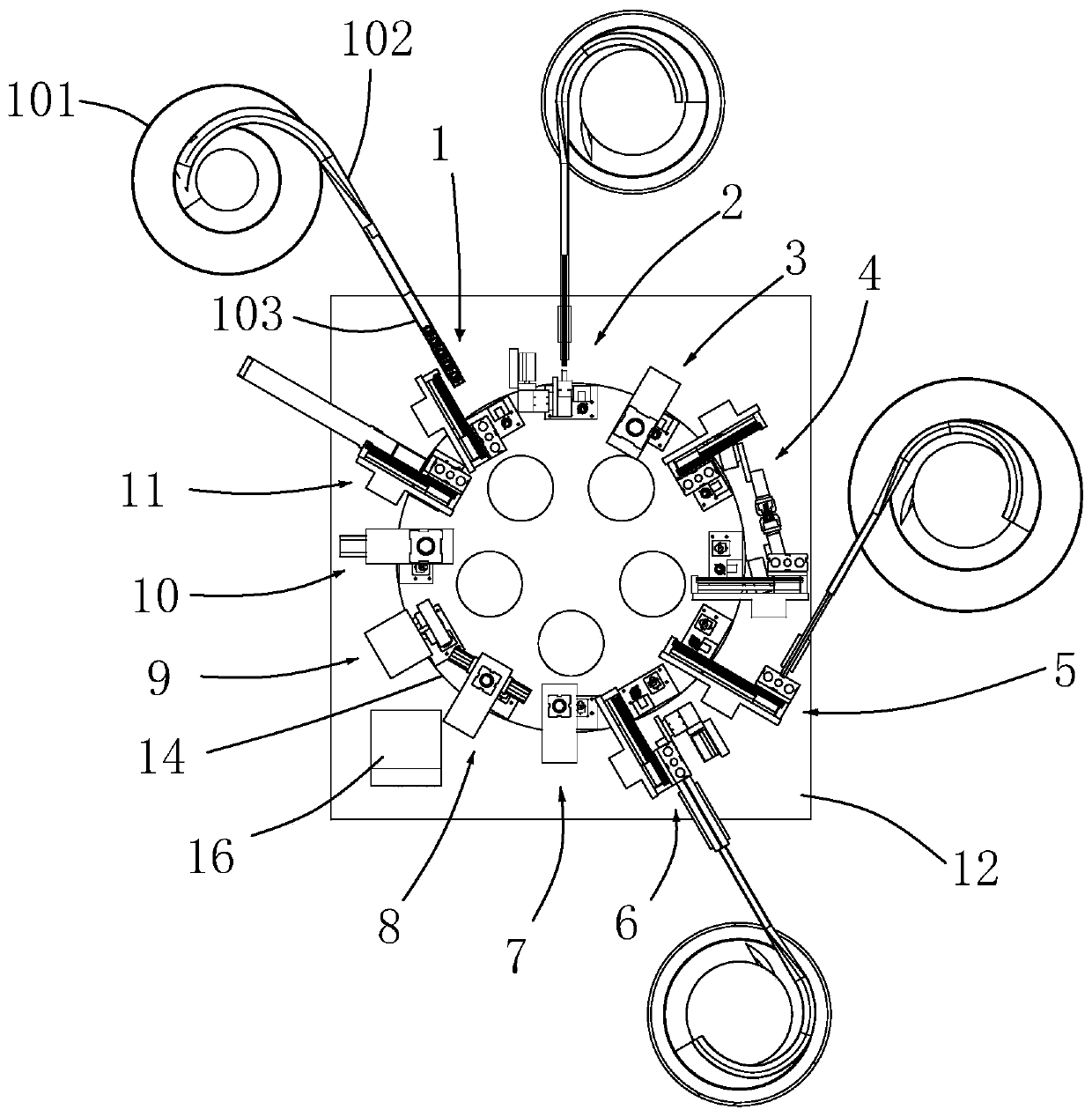

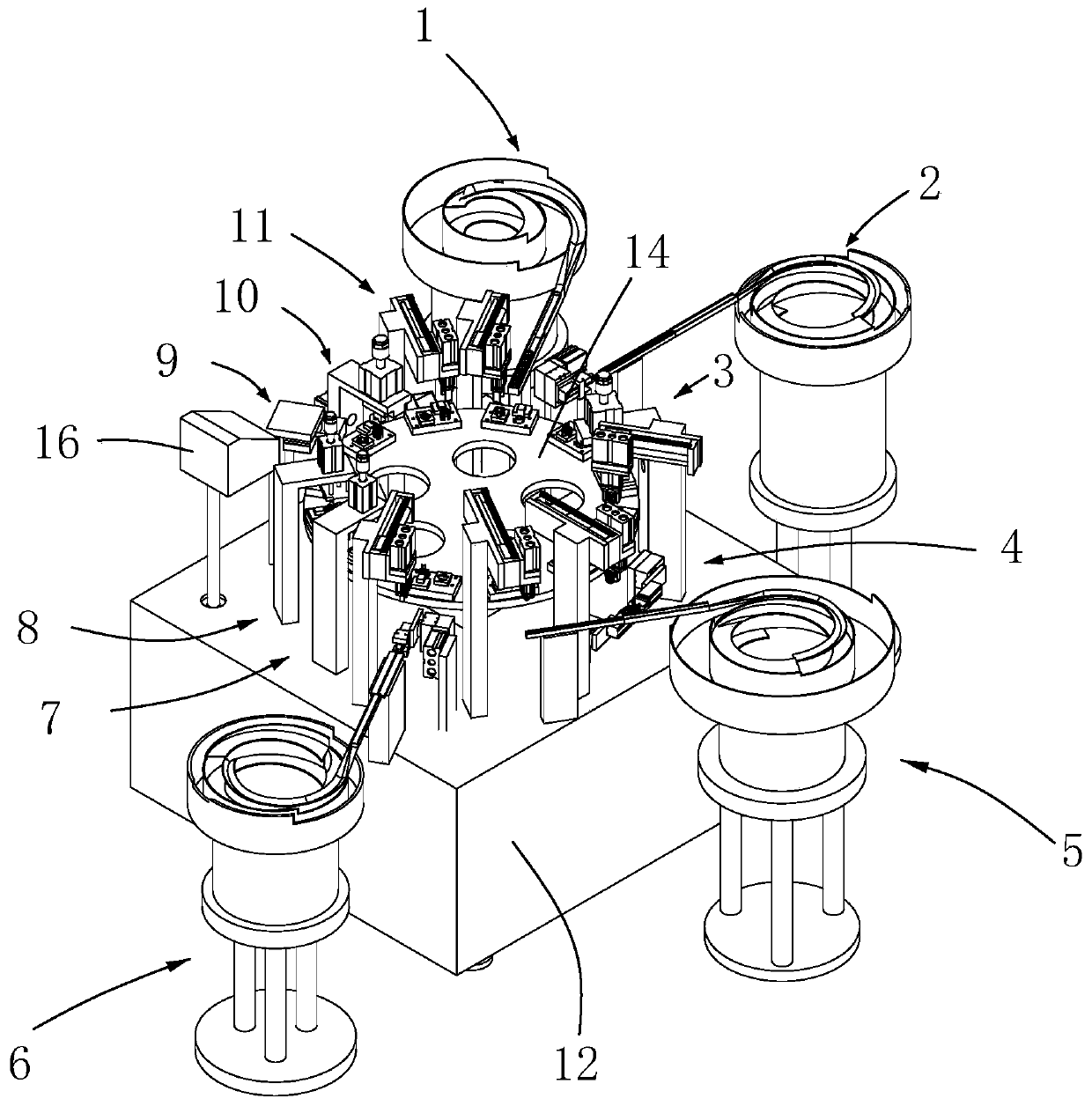

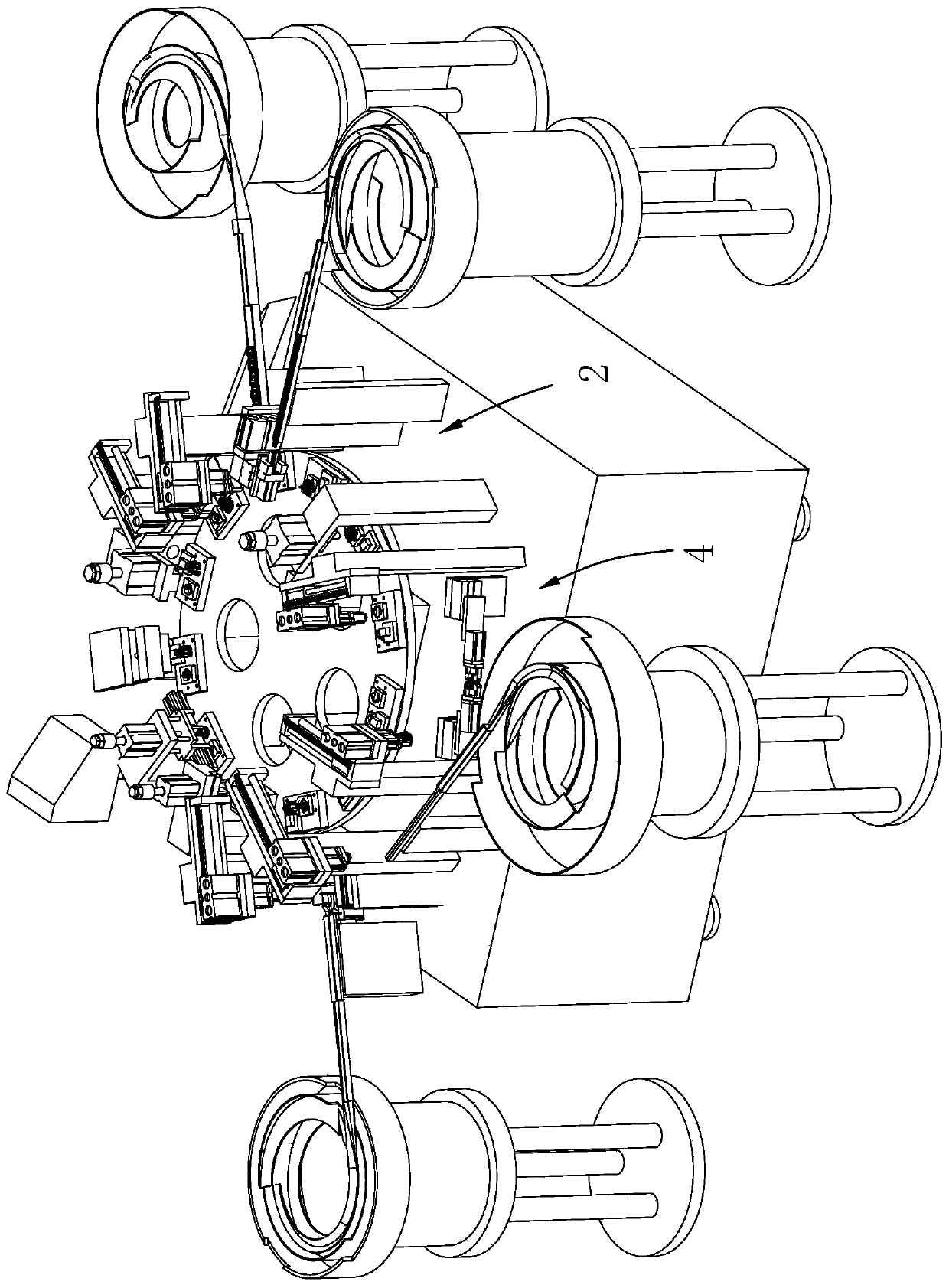

[0021] figure 1 The technical solution adopted for the present invention to solve the above-mentioned technical problems is: a balanced audio socket automatic assembly machine, including a machine platform 12, and the said machine platform 12 is provided with PLC, motor controller and other control devices, connection devices and other components. The four corners of the lower end surface of the machine table 12 are provided with adjustable mounting feet, and the mounting angles are threaded to adjust the height of the workbench, so that the mechanism on the workbench and the external mechanism can maintain the same height as possible.

[0022] The machine table 12 is fixedly connected with a rotating motor, the rotating motor is a servo motor, and the rotating motor only rotates at a fixed angle each time. The output end of the rotating moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com