Pipeline circumferential weld defect safety evaluation method

A technology for safety evaluation and girth welds, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, and the use of radiation for material analysis. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

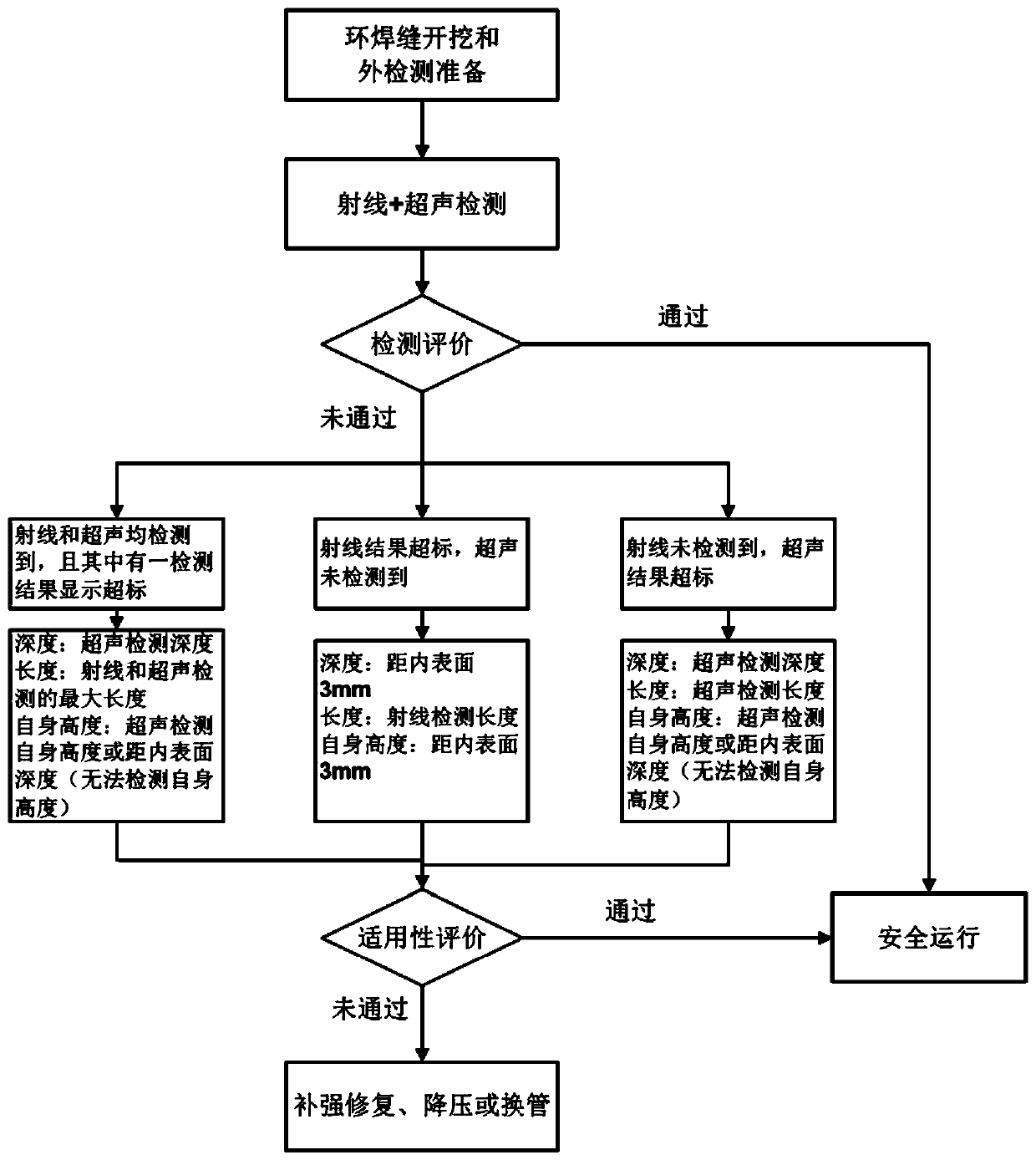

[0027] The following is attached figure 1 The principles and features of the present invention are described, and the examples given are only used to explain the present invention, and are not used to limit the scope of the present invention.

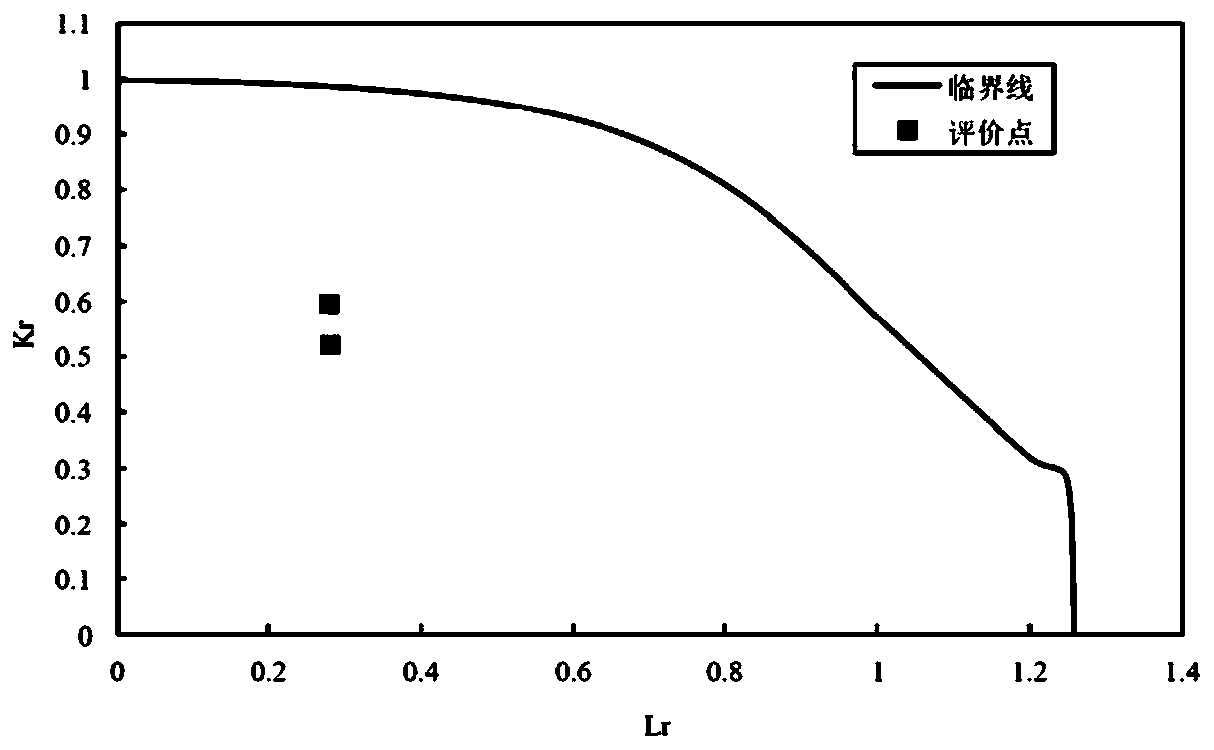

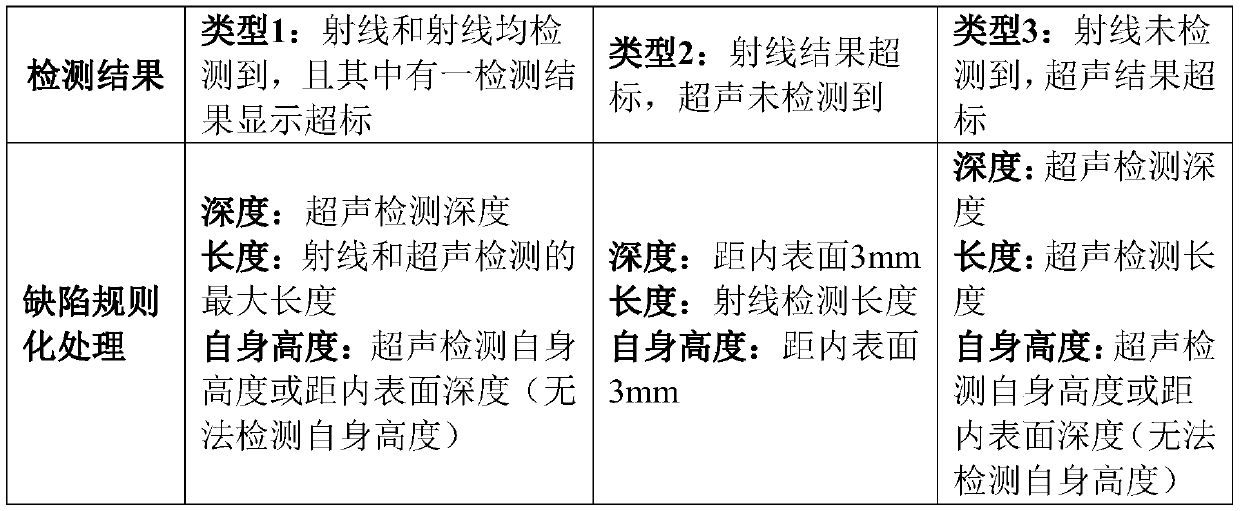

[0028] see figure 2 , on the basis of the non-destructive testing method and evaluation and testing results of the girth weld of oil and gas pipelines, the present invention establishes a regularized treatment principle for defects exceeding the standard, and the evaluation method for crack defects in SY / T 6477 or API 579, so as to realize the applicability of girth weld defects evaluate. Include the following steps:

[0029] (1) Carry out external inspection of pipeline girth weld with ray + ultrasonic;

[0030] (2) Carry out the detection and evaluation of X-ray + ultrasound results;

[0031] (3) Both ray and ray are detected, and one of the test results shows that it exceeds the standard; the ray result exceeds the standard, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com