Power battery group consistency detection method and device

A technology of a power battery pack and a detection method, which is applied in the direction of measuring devices, measuring electricity, and measuring electric variables, etc., and can solve problems such as the inability to reflect the voltage distribution of a single cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

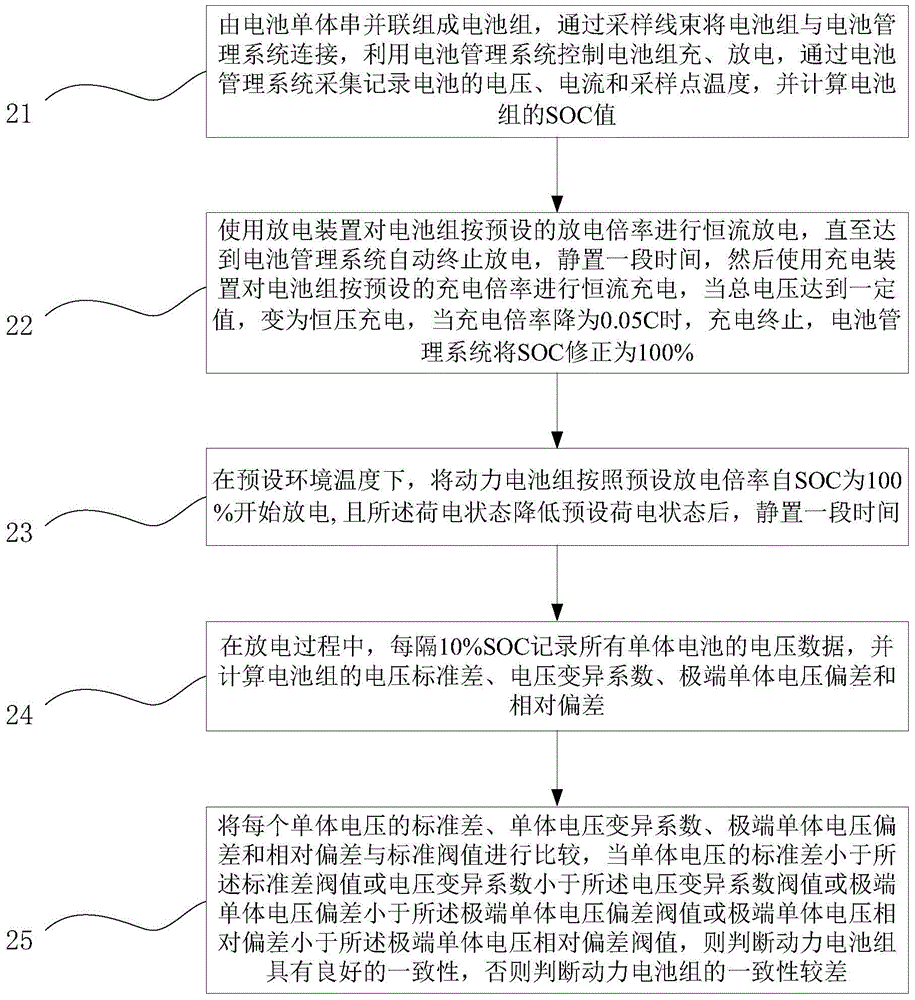

Image

Examples

Embodiment 1

[0092] The power battery pack in this embodiment uses a lithium iron phosphate power battery, the nominal voltage of the single battery is 3.20V, and the nominal capacity is 66Ah. The basic parameters of the power battery system are shown in Table 1:

[0093] Table 1

[0094] Single voltage / V 3.20 Monomer capacity / Ah 66 Total battery voltage / V 339.2 Total battery capacity / Ah 66 Total battery capacity / kWh 22.38 Grouping 1P106S

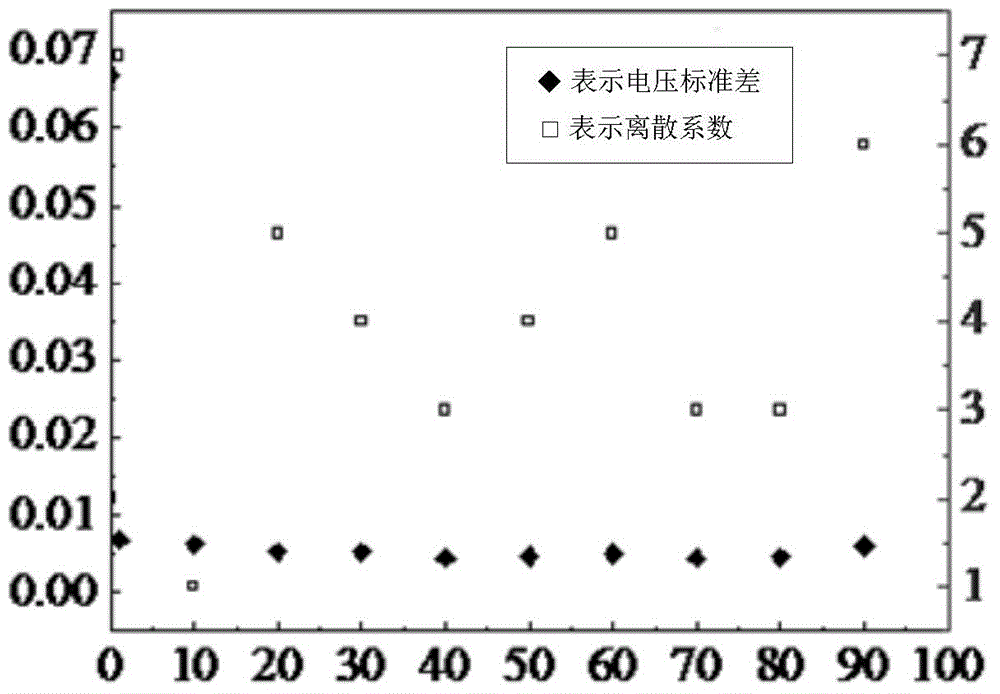

[0095] The power battery pack includes 106 single cells, which are v1~v106 respectively. Under the preset ambient temperature of 25°C, use a discharge device to discharge the power battery pack at a constant current discharge rate of 1 / 3C until it reaches the battery management level. After the system automatically terminates the discharge, it will be still for a period of time. Because at normal temperature, the DC internal resistance of the battery is basically unchanged, and the internal resistance consistency is...

Embodiment 2

[0101] The power battery system in this embodiment uses a lithium manganese oxide power battery, the nominal voltage of the single battery is 3.60V, and the nominal capacity is 90Ah. The basic parameters of the power battery system are shown in Table 3:

[0102] table 3

[0103] Single voltage / V 3.60 Monomer capacity / Ah 90 Total battery voltage / V 374.4 Total battery capacity / Ah 360 Total battery capacity / kWh 134.78 Grouping 4P104S

[0104] The power battery pack includes 104 single cells, which are v1~v104 respectively. Under the preset ambient temperature of 25°C, the discharge device is used to discharge the battery pack at a constant current discharge rate of 1 / 3C until it reaches the automatic discharge rate of the battery management system. Terminate the discharge and stand still for a period of time. Then use the charging device to charge the battery pack with a constant current at a charging rate of 1 / 3C. When the total voltage reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com