Electrochemical principle-based self-power generating type pressure sensor and preparation method thereof

A pressure sensor, electrochemical technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve problems such as performance degradation, and achieve the effects of reducing power consumption, fast response speed, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

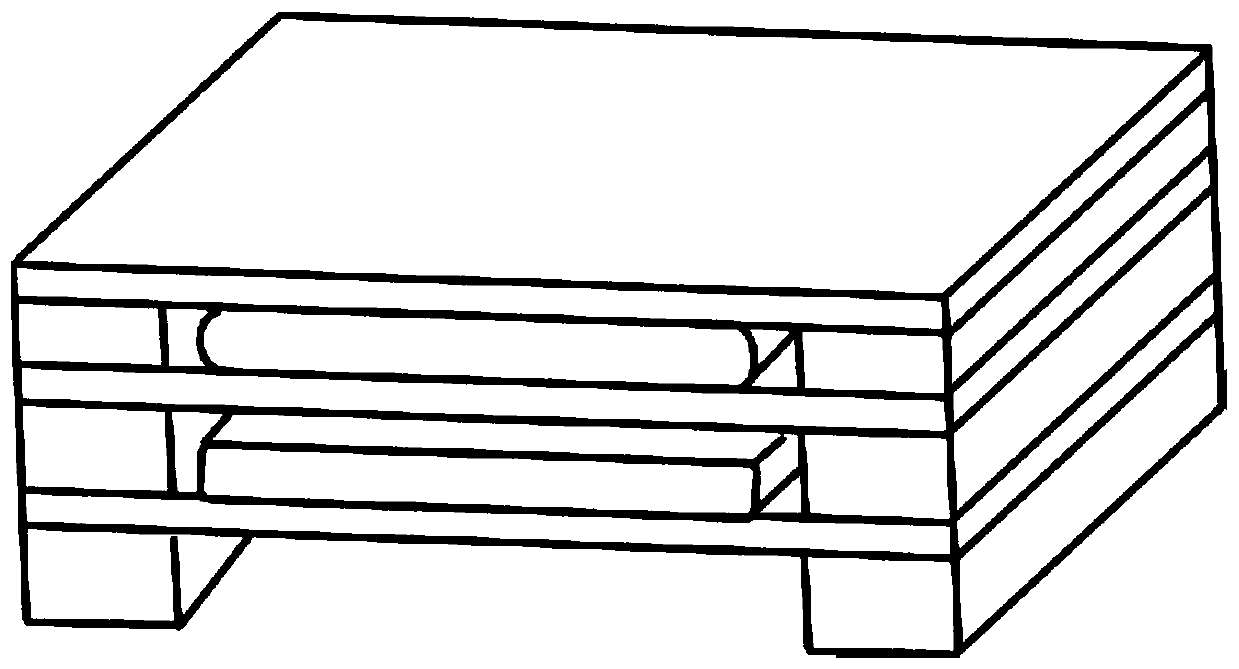

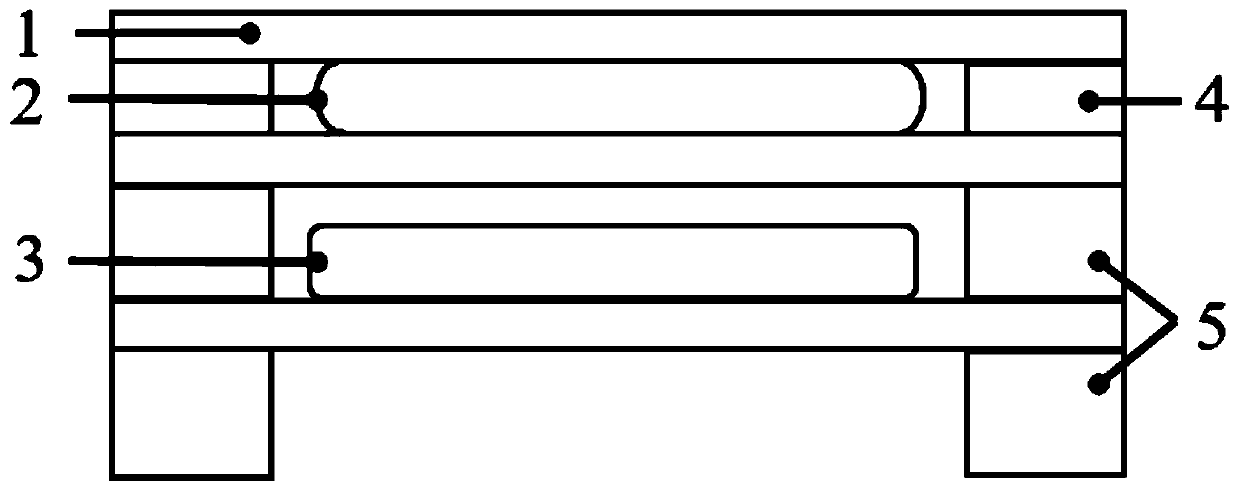

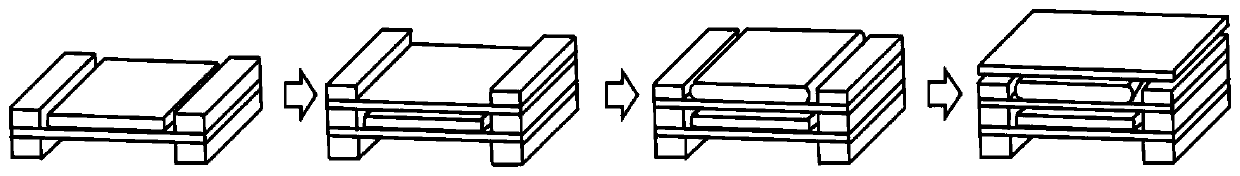

[0037] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the self-generating pressure sensor based on the electrochemical principle provided by the first embodiment of the present invention, the pressure sensor includes a sensing structure, a reference electrode, a current detection component and a processing and display component. The current detection component connects the sensing structure and the reference electrode to form a circuit. When the sensing structure is placed in the electrolyte to monitor the pressure, the dynamic pressure of the electrochemically available area of the working electrode 2 in the electrolyte Reduced under the action of , the sensing structure produces a potential change when the surface double layer balance charge of the working electrode 2 remains unchanged, thereby generating electrical energy output, and generating a current in the circuit, the current detection A component is used to detect the current and transmit the d...

Embodiment 2

[0063] see Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , the self-generating pressure sensor based on the electrochemical principle provided in the second embodiment of the present invention, the structure of the pressure sensor is basically the same as the self-generating pressure sensor based on the electrochemical principle provided in the first embodiment of the present invention, the difference is That is, the pressure sensor provided by this embodiment can be suitable for fresh water environment, and its sensing structure is accommodated in the sealed box 8, and the working electrode and the counter electrode are respectively connected to the outside world through waterproof wires 9, and the sealed box 8 A through hole is opened on one side adjacent to the pressing plate, and the through hole is used to accommodate the force conducting member 7 , and one end of the force conducting member 7 passes through the through hole and abuts against the pressin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com