Drying device used for processing of new material

A drying device and new material technology, applied in heating devices, dryers for static materials, drying and other directions, can solve the problems of low drying efficiency and complex structure, and achieve high drying efficiency, simple structure, good practicality Sexuality and Marketing Value Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

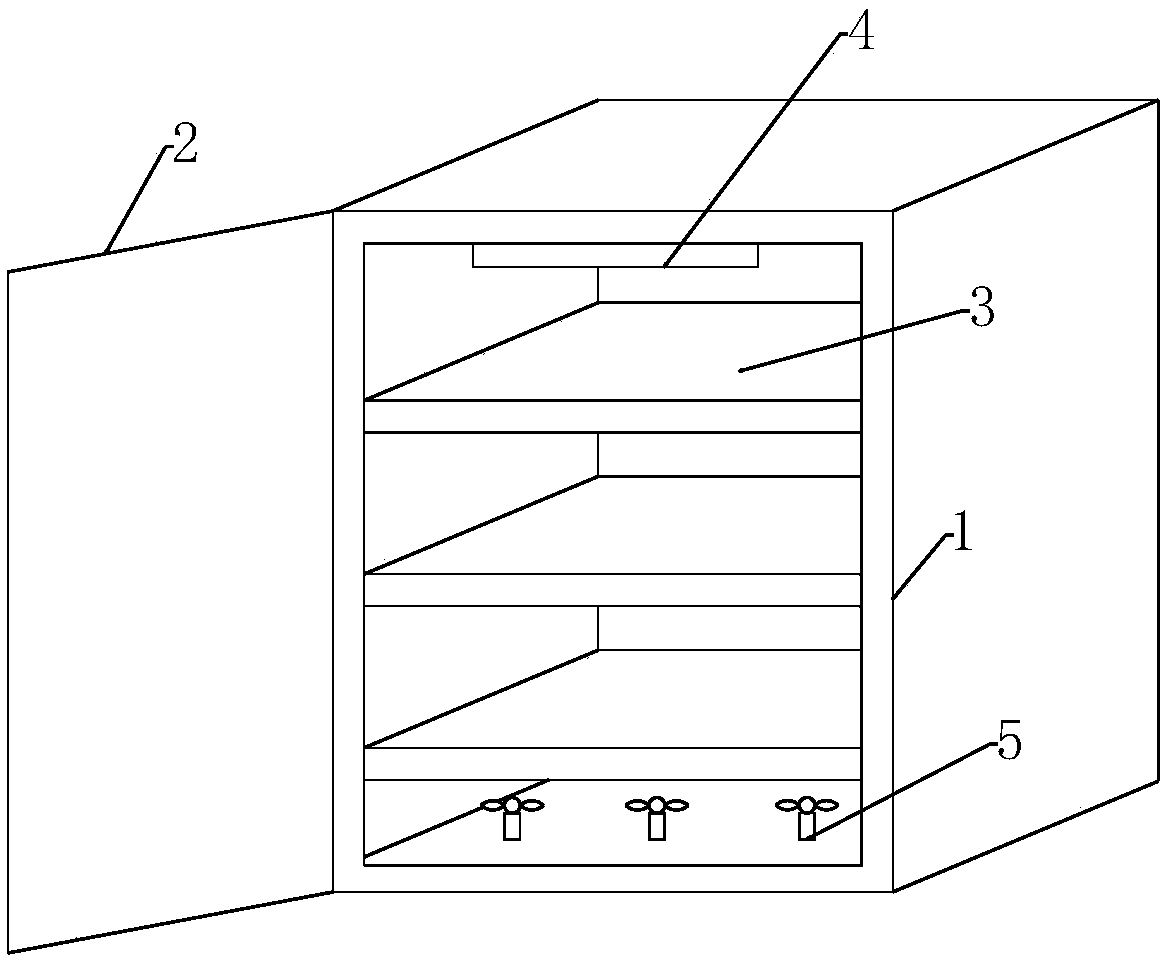

[0013] like figure 1 As shown, a drying device for new material processing provided in this embodiment includes an oven 1, a door 2 is rotatably provided on the oven 1, and a plurality of placement plates 3 are arranged in the oven 1, so The said placing plate 3 is a net-like structure, the inner top of the oven 1 is provided with a heating device 4, and the inner bottom of the oven 1 is provided with an air stirring device 5, so that the heating operation is realized by the heating device 4, and the oven is made by the air stirring device 5. 1 The inner temperature is more uniform.

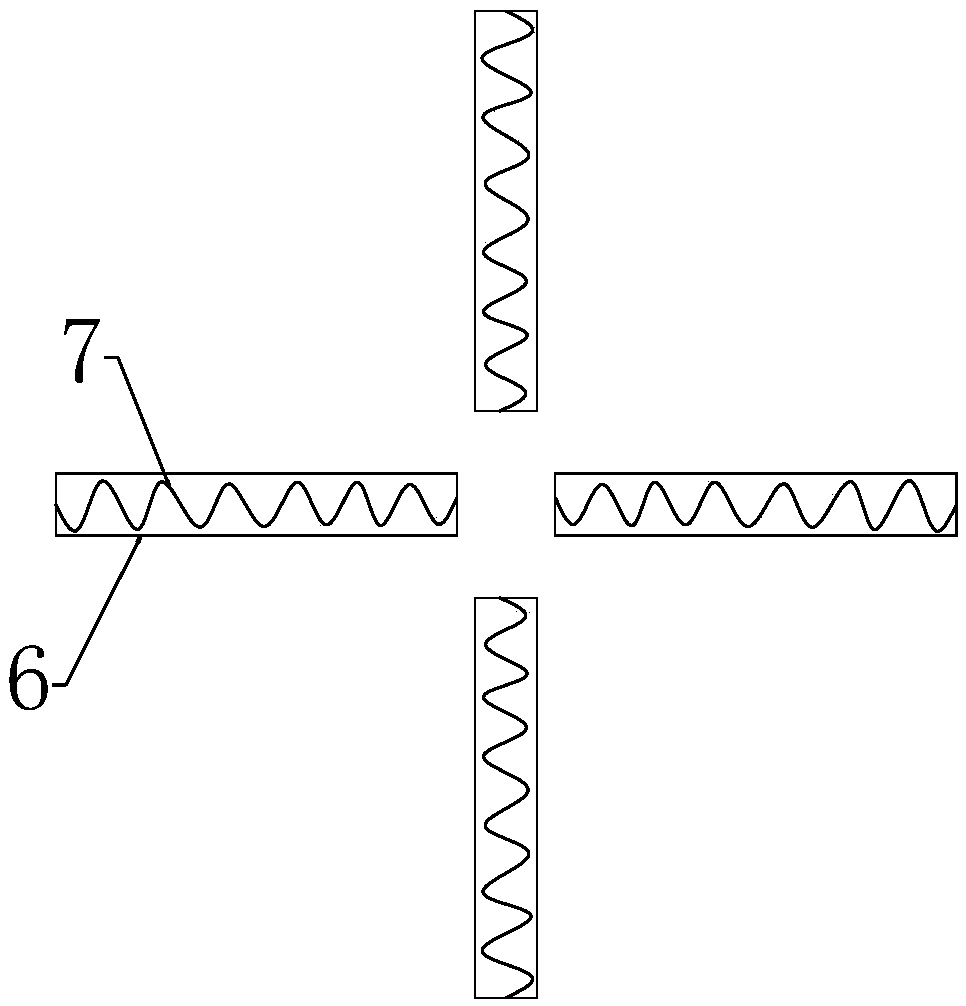

[0014] like figure 2 As shown, the heating device 4 preferably includes a plurality of quartz tubes 6, and electric heating wires 7 are arranged in the quartz tubes 6. Further, the plurality of quartz tubes 6 are cross-shaped at the top of the inner side of the oven 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com