Novel miniature diaphragm pump

A micro-diaphragm pump, a new type of technology, is applied in the field of water pump equipment and precision fluid transportation, which can solve the problems of large vibration noise and complex structure of diaphragm pumps, and achieve the effects of small vibration, reduced fluid working cycle, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with embodiments and drawings.

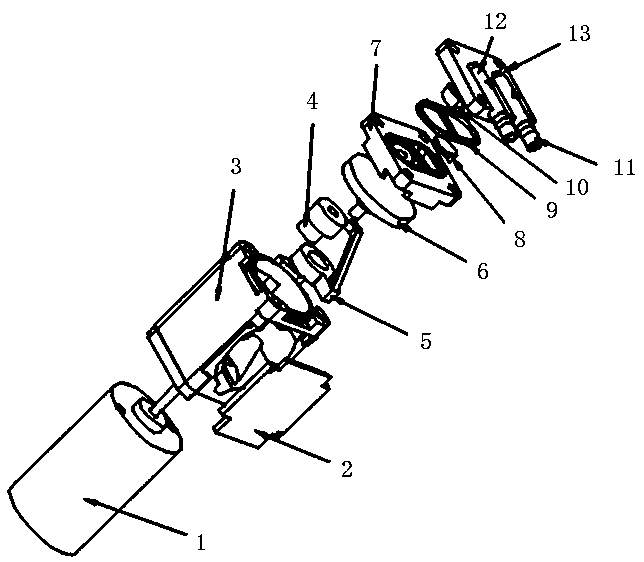

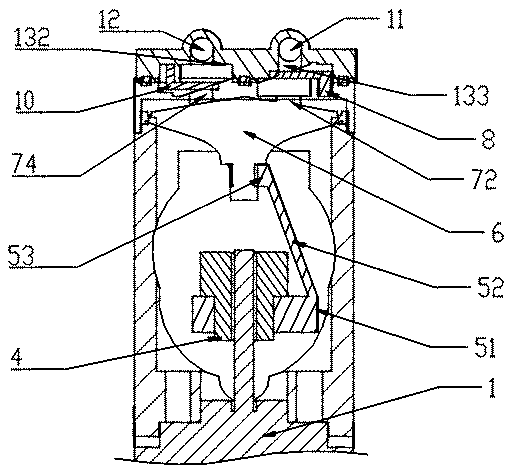

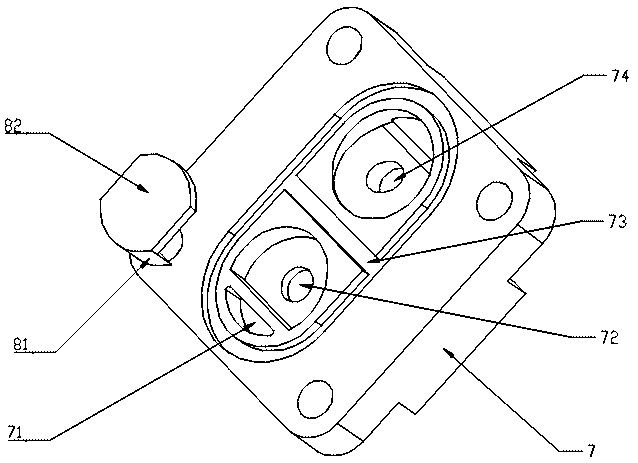

[0022] Such as figure 1 As shown, a new type of micro-diaphragm pump includes a motor 1, the output shaft of the motor 1 is provided with an eccentric wheel 4, the eccentric wheel 4 is sleeved with a sleeve assembly 5, the sleeve assembly 5 and a rubber diaphragm 6 is connected in the middle, and the center lines of the output shaft, the eccentric wheel 4, the sleeve assembly 5 and the rubber diaphragm 6 are located in the same direction (that is, parallel to each other).

[0023] Such as figure 1 As shown, a new type of micro diaphragm pump further includes a motor cavity 3, the output shaft of the motor 1 extends into the motor cavity 3 and is connected to the eccentric wheel 4, and the sleeve assembly 5 is also located inside the motor cavity 3 (the motor cavity The side of 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com