Large-temperature-difference freeze-thaw cycle method for production increase of surface borehole

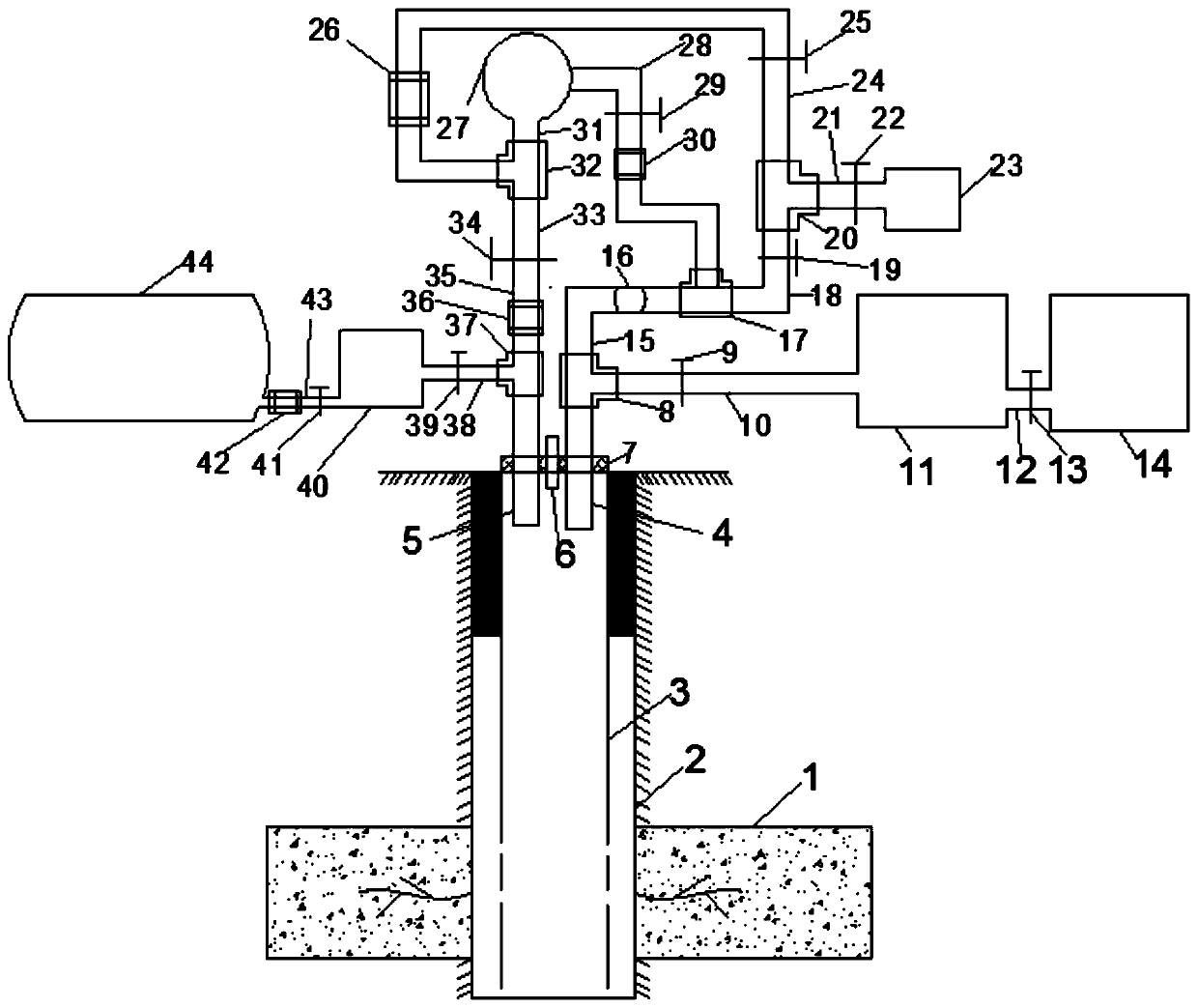

A surface drilling and freeze-thaw cycle technology, which is applied in earthwork drilling, wellbore/well components, gas discharge, etc., can solve problems such as unsatisfactory application effect, restricted gas drainage effect, and difficulty in forming long fractures. Achieve the effect of increasing cracking effect, improving cracking effect, and good cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below.

[0023] Concrete steps of the present invention are:

[0024] A. When the gas flow in the gas drainage pipe is greatly reduced to 8m 3 , open the first valve 9 and the second valve 13, start the magnetized water generator 14 and the pulsation pump 11, the magnetized water is pulsated by the pulsation pump 11 to obtain pulsating magnetized water, and the pulsating magnetized water passes through the third pipeline 12, the second pipeline The pipeline 10 and the first pipeline 4 enter the gas drainage pipe 3, and the gas drainage pipe 3 is cleaned and impacted on the coal seam 1, so that the cracks in the coal body develop and expand, and the pulsation frequency of the pulsating magnetized water is controlled to be 0.05 Hz to 0.3 Hz. The pulsation pressure is 12MPa~18MPa, and the pulsation time is 30min~45min;

[0025] B. After the injection of the pulsating magnetized water is completed, close the magnetized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com