Humidification flame retardant fire door

A fire-proof door and humidification technology, applied in the field of fire-proof doors, can solve the problems of high surface temperature of fire-proof doors, poor flame-retardant effect, and inability to cool down the surface of fire-proof doors, so as to reduce dead angle of cooling and enhance practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

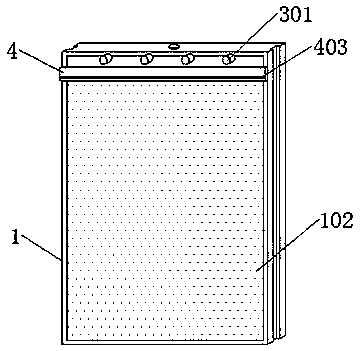

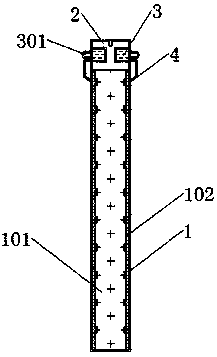

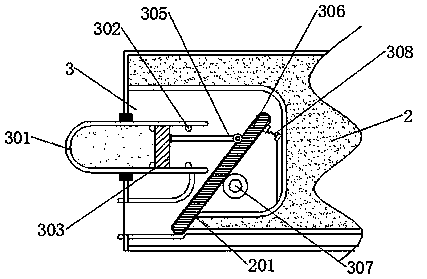

[0028] as attached figure 1 to attach Figure 5 Shown:

[0029] The present invention provides a humidified flame-retardant fire door: the humidified flame-retardant fire door includes a door body 1, a flame-retardant filling layer 101, a surface blocking layer 102, a liquid storage tank 2, a water outlet 201, a working chamber 3, a pipe Body 301, limiting layer 302, sealing block 303, sealing strip 304, connecting rod 305, movable rod 306, runner 307, spring 308, liquid separator 4, liquid collecting port 401, gauze layer 402 and liquid outlet groove 403, The inside of the door body 1 is embedded with a flame-retardant filling layer 101, and the front and rear ends of the door body 1 are closely fitted with a surface barrier layer 102. The top opening of the door body 1 has a liquid storage tank 2, and the lower left corner of the liquid storage tank 2 There is a water outlet 201 in the lower right corner and the lower right corner. The left and right sides of the liquid st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com