Novel super-large transverse displacement modular multi-directional displacement expansion joint

A technology of lateral displacement and multi-directional displacement, applied in the directions of bridge parts, bridges, buildings, etc., can solve the problems of small displacement change, reduce the service life of bridge expansion joints, affect the normal operation of bridge expansion joints, etc., and achieve increased stability. performance, guaranteeing the effect of scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

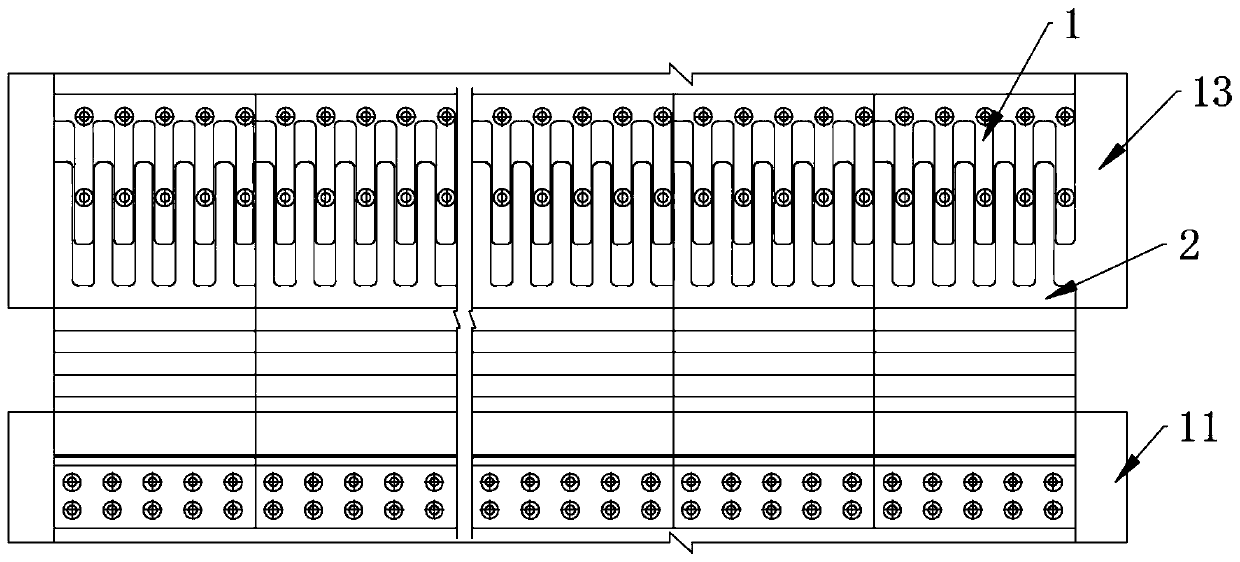

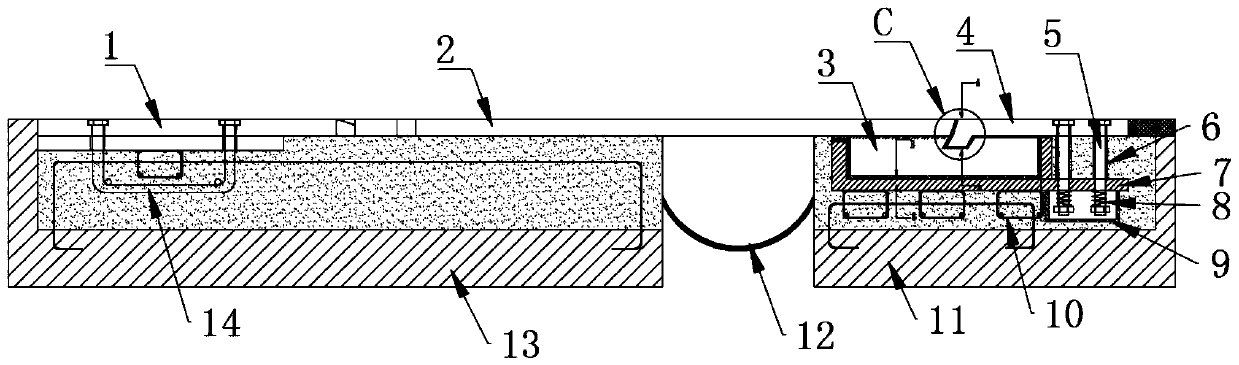

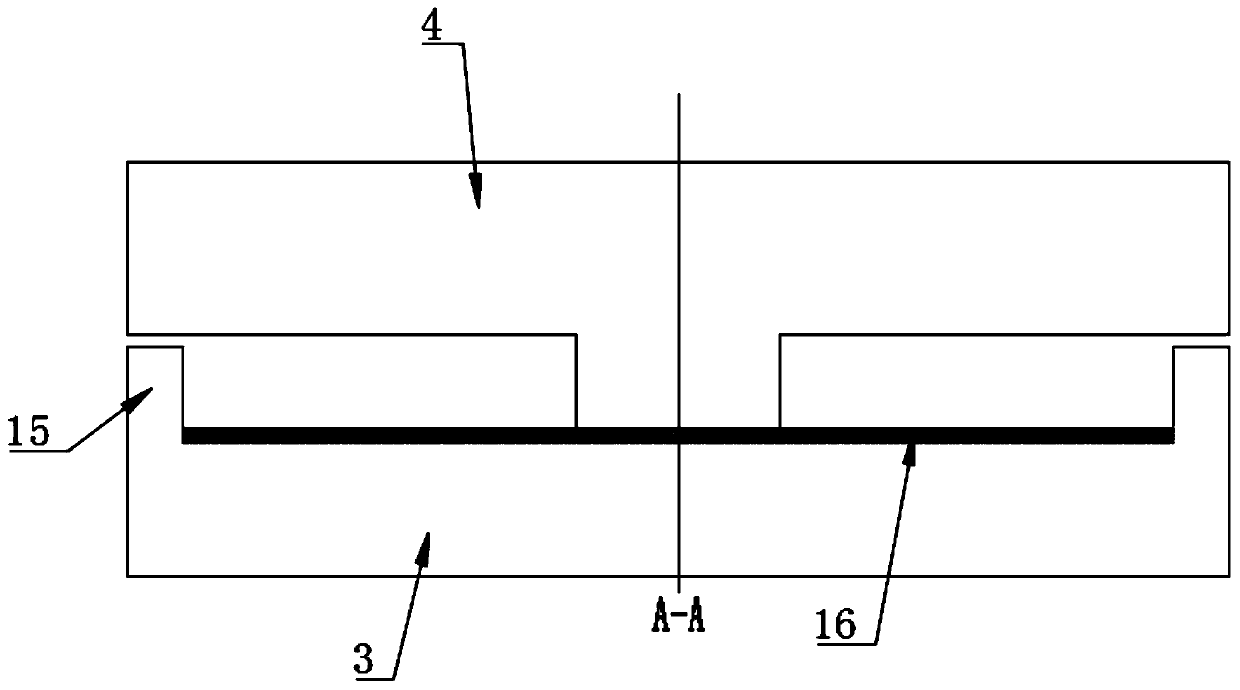

[0030] Such as Figure 1 to Figure 6 As shown, a novel super large lateral displacement modular multi-directional displacement expansion joint of the present invention includes a main tooth plate 2 and an auxiliary tooth plate 1. The comb teeth of the main tooth plate 2 and the auxiliary tooth plate 1 cross each other and have gaps. One end of the tooth plate 2 is erected on the first bridge beam body 11, and the other end spans the gap between the first bridge beam body 11 and the second bridge beam body 13 and is installed on the second bridge beam body 13. The auxiliary tooth plate 1 is installed on the second bridge girder body 13, and the bottom surface of the main tooth plate 2 erected on the first bridge girder body 11 is fixedly connected with one part of the top surface of the lateral displacement plate 3, and the other part of the top surface of the lateral displacement plate 3 , the main teeth are connected with one end of the displacement plate cover plate 4 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com