Knitted single-suede fabric for sewage treatment and manufacturing method thereof

A sewage treatment and manufacturing method technology, applied in the direction of knitting, warp knitting, textiles and papermaking, etc., can solve the problems of affecting the filtering effect and service life, low production efficiency of filter cloth, insufficient space between knitting chains, etc., to improve production Efficiency, strong three-dimensional effect, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: A method for manufacturing knitted cut pile fabrics for sewage treatment, using a domestic double-needle bed Raschel warp knitting machine for weaving, then setting the shape, cutting width, and finishing. Proceed as follows:

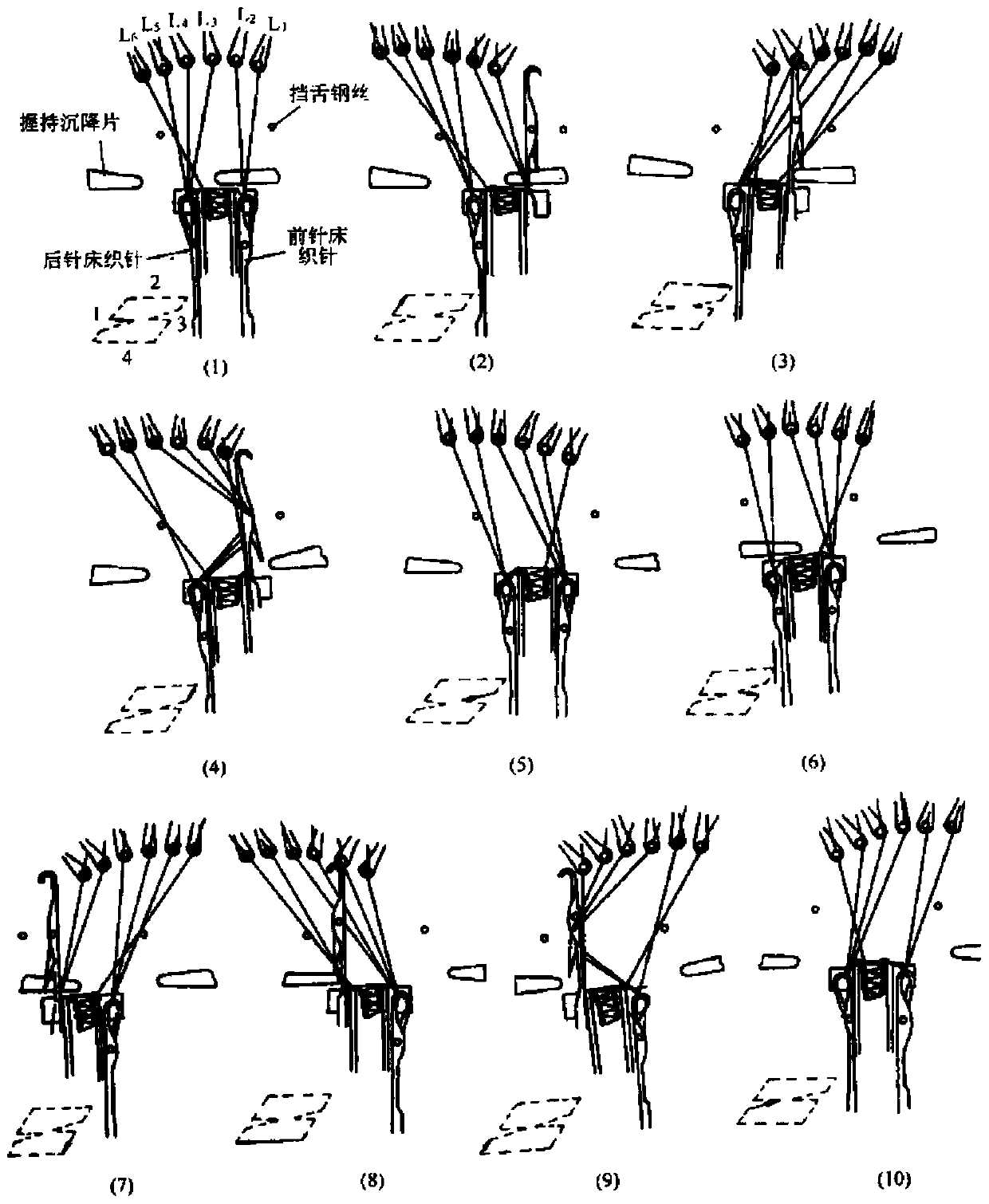

[0041] (1) Weaving

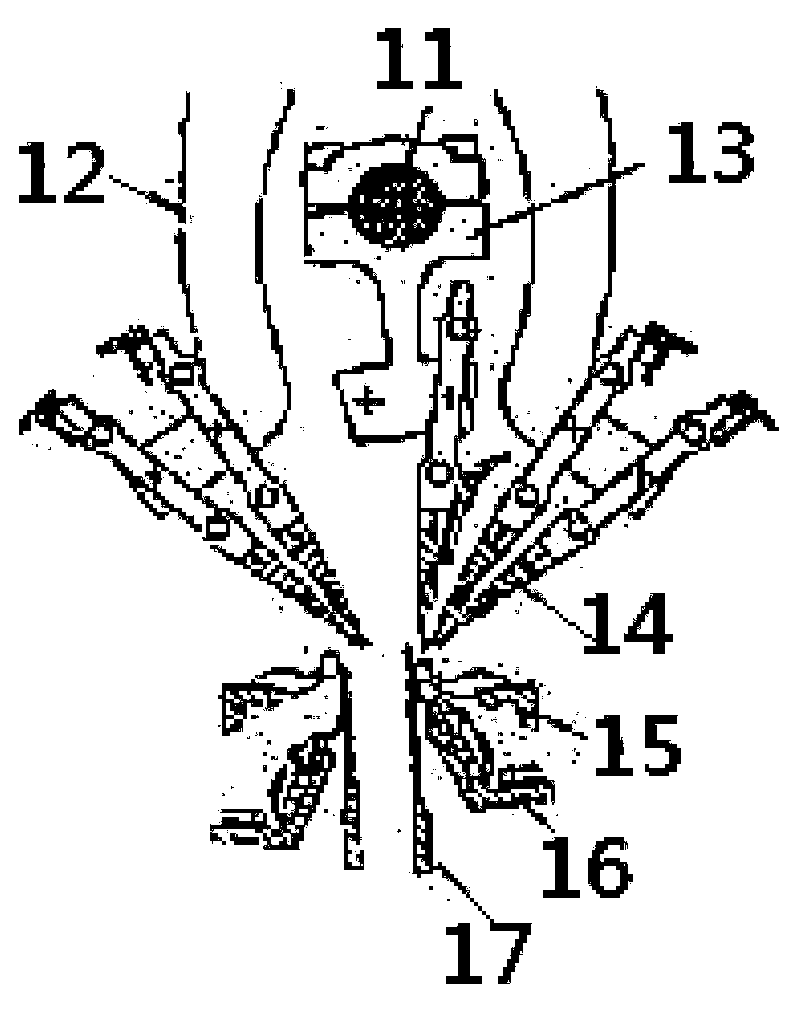

[0042] Double-width weaving using a commonly used double-needle bed warp knitting machine: the weave structure is a warp knitting structure, and the laying method is the same direction laying yarn, which is woven by closed-end chain knitting; the warp yarn is divided into ground warp and pile warp (see figure 1), the ground warp is knitting chain and weft insertion, the knitting chain uses polyester filament, the weft insertion is composed of polyester filament and high twist polyester yarn; the velvet warp is polyester acrylic yarn or acrylic yarn, and the velvet yarn is hung on the knitting chain, Weaving back and forth between two layers of base fabric to form a fabric; the raw material of the ground warp is 15...

Embodiment 2

[0051] Embodiment 2: As described in Embodiment 1, the difference is:

[0052] The used double needle bed warp knitting machine is made up of 5 combs, and the speed of a machine is 900r / min. The raw material of the ground warp is 150D / 35F polyester filament and twisted 300D / 288F polyester filament in a ratio of 2:1, and the pile warp is 25NM / 2D pre-expanded acrylic yarn.

[0053] The post-finishing process conditions are as follows: dry expansion temperature is 100°C, time is 25 minutes, holding time is 5 minutes; gluing is applied by rolling glue and scraping at the same time, the gluing interval is 5mm, the cloth speed is 14m / min, and the temperature is 130°C; The shearing speed is 15m / min, and the gauge is 13mm; the carding gauge is 2, and the carding depth is 2 / 3 of the carding depth; the second shearing speed is 15m / min, and the gauge is 13mm.

[0054] The performance index of the product is that the pile height is 12mm, the gap between the knitting chain and the knittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com