Method and system for directly preparing alcohol from coke oven gas

A technology of coke oven gas and coke oven gas, which is applied in the field of coke oven gas, can solve the problems of increasing gasifier consumption, high cost, and small adjustable range, so as to reduce water consumption, alleviate energy crisis problems, The effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The production product is ethanol.

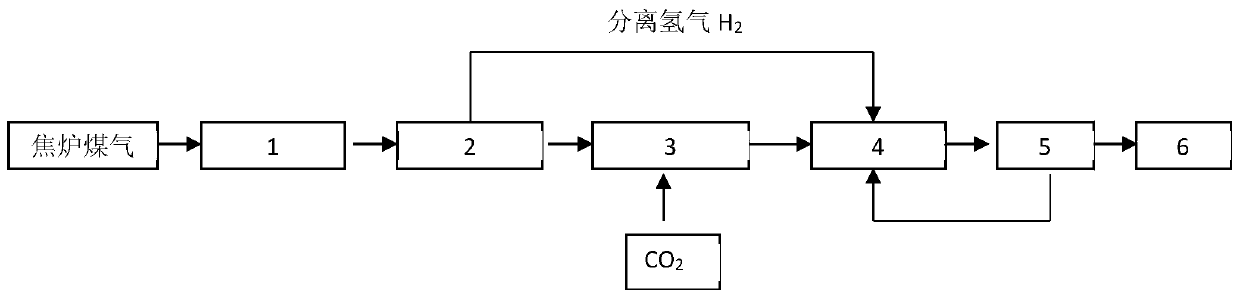

[0045] The composition of coke oven gas is hydrogen (58v%) and methane (24v%), carbon monoxide (8v%), unsaturated hydrocarbons above C2 (3v%), carbon dioxide (2v%), oxygen (0.5v) %), nitrogen (4v%), containing sulfide 200-500mg / Nm 3 . Such as figure 1 As shown in the process flow, the coke oven gas is dedusted and desulfurized by the desulfurization purification device 1 to obtain refined coke oven gas. The purified coke oven gas has a hydrogen content of 58%, a hydrogen-carbon ratio of 5.6, and a methane content of 24v %, the sulfur content is less than 40mg / Nm 3 , And then the PSA separation hydrogen extraction device 2 separates hydrogen and extracts the hydrogen from the coke oven gas. After hydrogen extraction, the methane content in the coke oven gas is 62v%, and the rest is carbon monoxide, carbon dioxide, C2 and above hydrocarbons and nitrogen. After hydrogen extraction The coke oven gas is mixed with carbon dioxide in a volum...

Embodiment 2

[0047] The production product is methanol.

[0048] The composition of coke oven gas is hydrogen (55v%) and methane (27v%), carbon monoxide (5v%), unsaturated hydrocarbons above C2 (3v%), carbon dioxide (1.5v%), oxygen (0.3 v%), nitrogen (3v%), containing sulfide 200-500mg / Nm 3 . After the coke oven gas is dedusted and desulfurized by the desulfurization purification device 1, refined coke oven gas is obtained. The purified coke oven gas has a hydrogen content of 55v%, a hydrogen to carbon ratio of 8.2, and a sulfur content of 30mg / Nm 3 , And then the PSA separation hydrogen extraction device 2 separates hydrogen and extracts the hydrogen from the coke oven gas. After the hydrogen is removed, the methane in the coke oven gas is 68.4v%, and the rest is carbon monoxide, carbon dioxide, C2 and above hydrocarbons and nitrogen. The coke oven gas and carbon dioxide are reformed in the methane carbon dioxide dry reformer 3 according to the volume ratio of 1.4:1, the reaction temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com