Rubber ring lifter

A hoist and apron technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient roller pressing and overlapping of aprons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

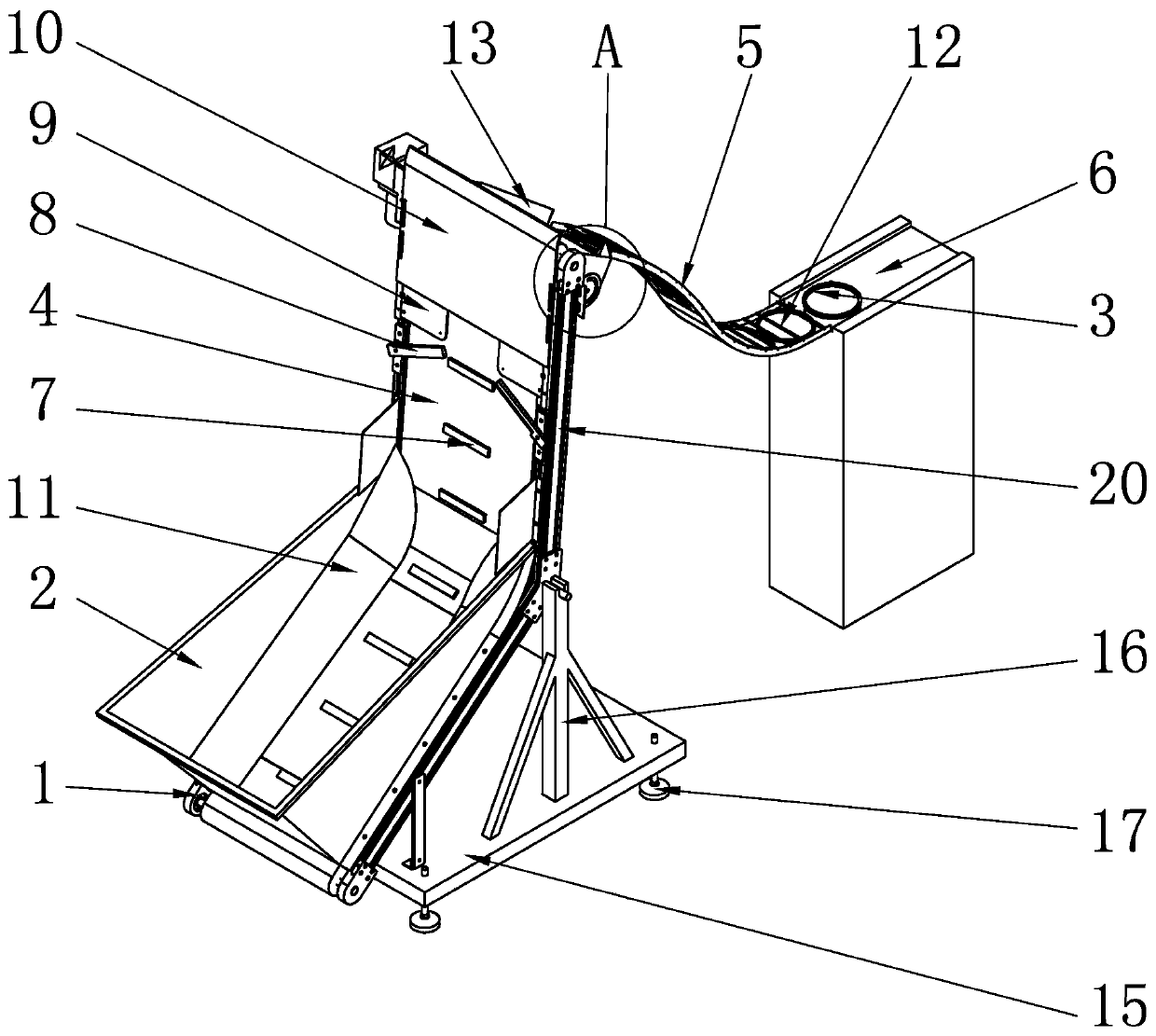

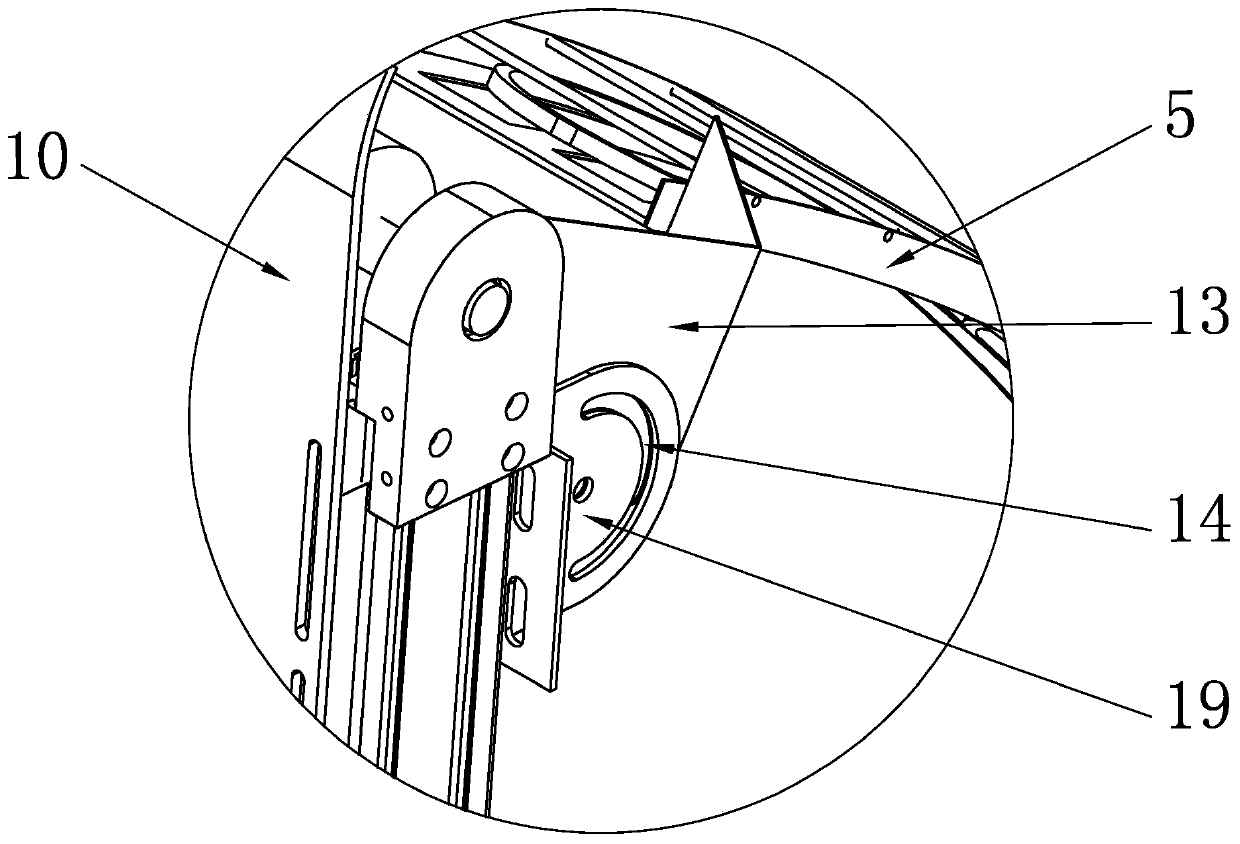

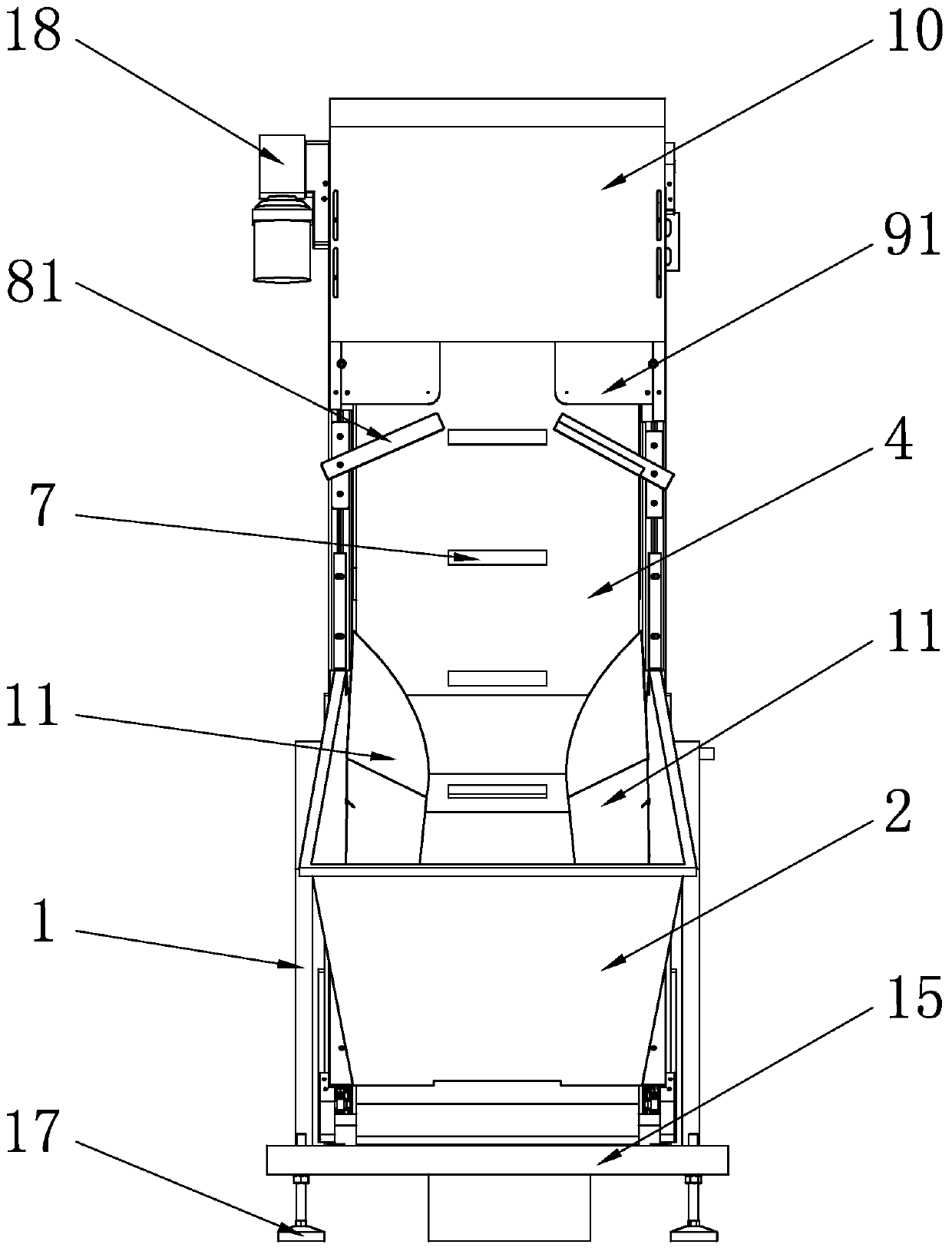

[0022] see figure 1 with image 3 , a kind of apron lifter of the present invention, comprises frame 1 and the vertical board 20 that is arranged on frame 1 and hopper 2, can place several rubber rings 3 in described hopper 2, the bottom of described hopper 2 and vertical board 20 is provided with conveyor belt 4, and described conveyor belt 4 is driven by motor 18, and the output end of described conveyor belt 4 is connected with receiving platform 6 through slideway 5, and the output end of described conveyor belt 4 is arranged on stand plate 20 and Higher than the hopper 2, the conveyor belt 4 is provided with several lifting plates 7 along the conveying direction, and the distance between two adjacent lifting plates 7 is greater than the width of one apron and less than the width of two aprons. Height-limiting part 8 and width-limiting part 9, described height-limiting part 8 and width-limiting part 9 are all arranged on the top of conveyer belt 4, and described height-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com