Wine box base shell bonding device

A bonding device and casing technology, which is applied in packaging, transportation and packaging, box making operations, etc., can solve the problems of operator fatigue, unguaranteed bonding effect of wine box base shell, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

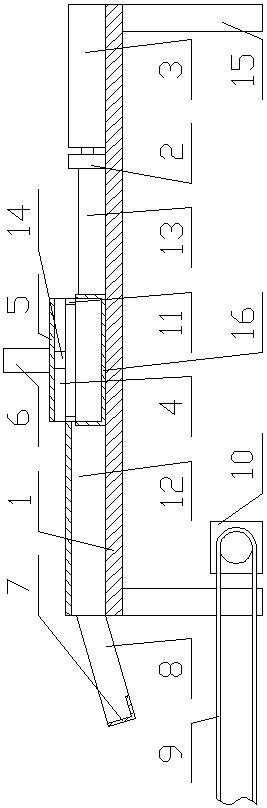

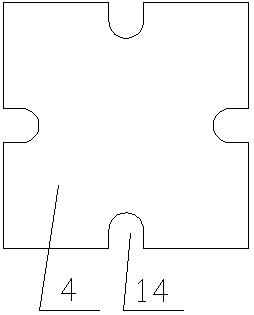

[0032] to combine figure 1 and figure 2It can be seen that the present invention includes a base plate 1, and the top surface of the base plate 1 is provided with a push plate 2, a pressure plate 4 and a discharge port in sequence, and the push plate 2 reciprocates along the top surface of the base plate 1 facing or facing away from the pressure plate 4 , a top plate 5 is fixed above the base plate 1, and the press plate 4 reciprocates up and down between the top plate 5 and the base plate 1, perpendicular to the top surface of the base plate 1, and the inner opening of the press plate 4 and the wine box base shell 16 Matching, the bottom of the substrate 1 is located at the discharge port and is provided with a discharge conveyor belt 9; the top surface of the substrate 1 is provided with a feeding area between the push plate 2 and the pressure plate 4, and the push plate 2 is located far away from the pressure plate. 4, the distance between the push plate 2 and the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com