A bonding method, system, device and device

A coordinate system and camera technology, applied in the field of bonding methods, equipment and devices, and systems, can solve the problems of high error rate, a large amount of manpower, and low efficiency of manual bonding products, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

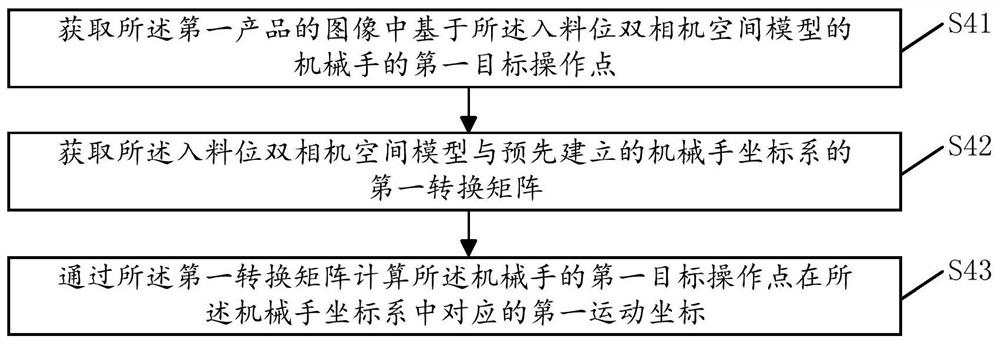

[0061] see figure 1 , figure 1 It is a flowchart of a bonding method provided in Embodiment 1 of the present invention; including:

[0062] S1. Obtain the images of the first product captured by the first camera and the second camera respectively, and respectively establish the coordinate system of the images of the first product; wherein, the shooting heights of the first camera and the second camera are at the same level;

[0063] S2. Obtain the images of the second product respectively captured by the third camera and the fourth camera and respectively establish the coordinate system of the images of the second product; wherein, the shooting heights of the third camera and the fourth camera are at the same level;

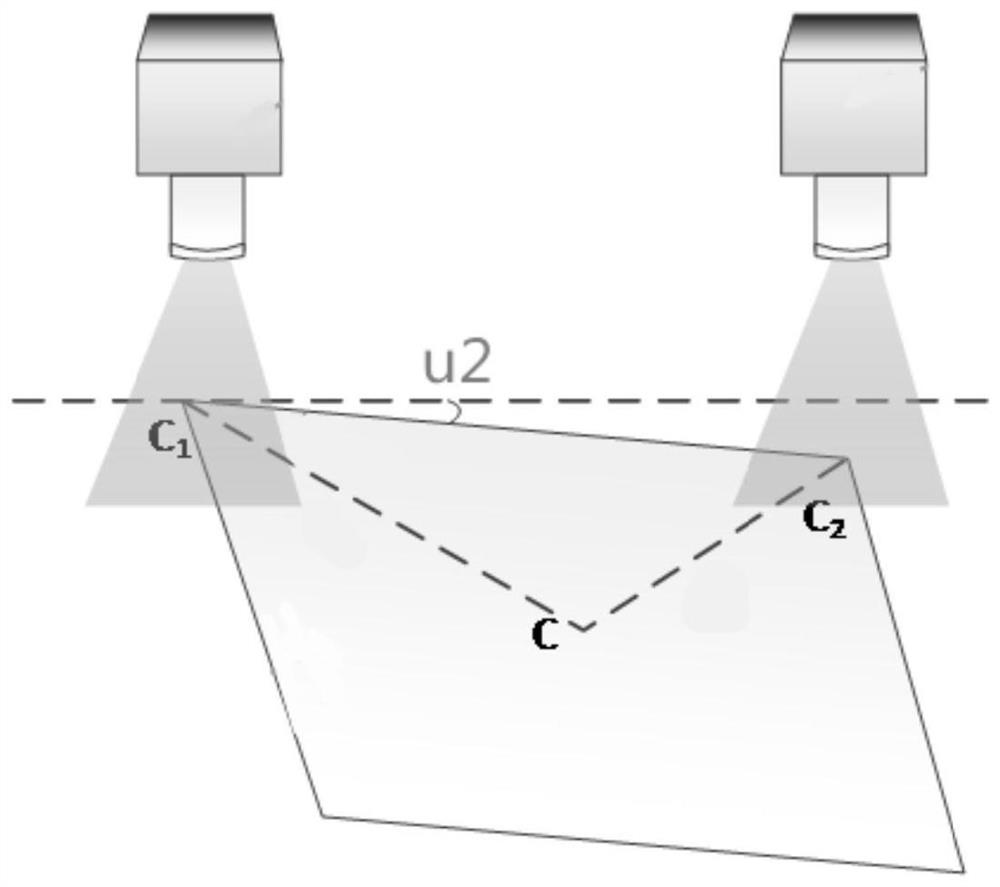

[0064] S3. Establish a dual-camera space model of the first camera and the second camera at the feed level according to the coordinate system of the image of the first product, and establish the first camera according to the coordinate system of the image of the...

Embodiment 2

[0106] see Figure 9 , Figure 9 It is a structural schematic diagram of an adhesive system 20 provided in Embodiment 2 of the present invention; including:

[0107] The product image acquiring unit 21 is used to acquire the images of the first product taken by the first camera and the second camera respectively and respectively establish the coordinate system of the images of the first product, and is also used to acquire the images taken by the third camera and the fourth camera respectively. The image of the second product and establish the coordinate system of the image of the second product respectively; Wherein, the shooting height of the first camera and the second camera are equal, and the shooting height of the third camera and the fourth camera flush;

[0108] The dual-camera space model unit 22 is used to establish the dual-camera space model of the first camera and the second camera according to the coordinate system of the image of the first product; The coordi...

Embodiment 3

[0141] see Figure 12 , Figure 12 It is a schematic structural diagram of a bonding device 30 provided in Embodiment 3 of the present invention; the bonding device 30 of this embodiment includes: a processor 31, a memory 32, and A computer program that runs. When the processor 31 executes the computer program, the steps in the above-mentioned embodiments of the bonding method are realized, for example figure 1 Steps S1-S5 are shown. Or, when the processor 31 executes the computer program, it realizes the functions of each unit in the above embodiment of the bonding system, for example, the function of the product image acquisition unit 21 .

[0142] Exemplarily, the computer program can be divided into one or more modules / units, and the one or more modules / units are stored in the memory and executed by the processor 31 to implement the present invention . The one or more modules / units may be a series of computer program instruction segments capable of accomplishing speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com