Automatic cleaning device for fiber cutter

An automatic cleaning and cutter technology, applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of spending 40-60 minutes, delaying construction efficiency, etc., to achieve convenient use and operation, reduce The effect of reasonable labor intensity and structural composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

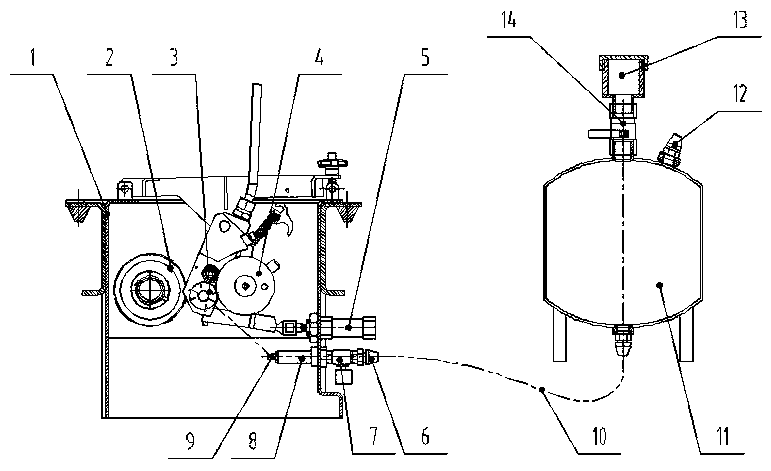

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, an automatic cleaning device for a fiber cutter according to the present invention, the fiber cutter includes a fiber cutting bin 1 equipped with one or more fiber cutter assemblies, and the fiber cutting bin 1 It includes an thimble cylinder 5 capable of ejecting the fiber cutter assembly, and a driving steel wheel 2 that drives the blade holder 3 to rotate. For fiber filaments, the automatic cleaning device includes an oil tank 11 that can be filled with cleaning liquid, and the oil tank 11 is connected to the narrow-angle nozzle 9 built in the fiber cutting bin 1 through a high-pressure oil pipe 10 and an electromagnetic ball valve 7 , the narrow-angle nozzle 9 is facing the blade frame 3 and the driven rubber wheel 4.

[0011] As shown in the figure: the narrow-angle nozzle 9 is connected to a transition joint 8 fixed in the fiber cutting chamber 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com