Pulverized material dust collection chamber

A technology for dust collection and crushing, which is applied in the fields of dust removal, cleaning methods and utensils, grain processing, etc., which can solve the problems of difficult dust collection and air pollution, and achieve the effect of simple structure, convenient use, and no harm to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

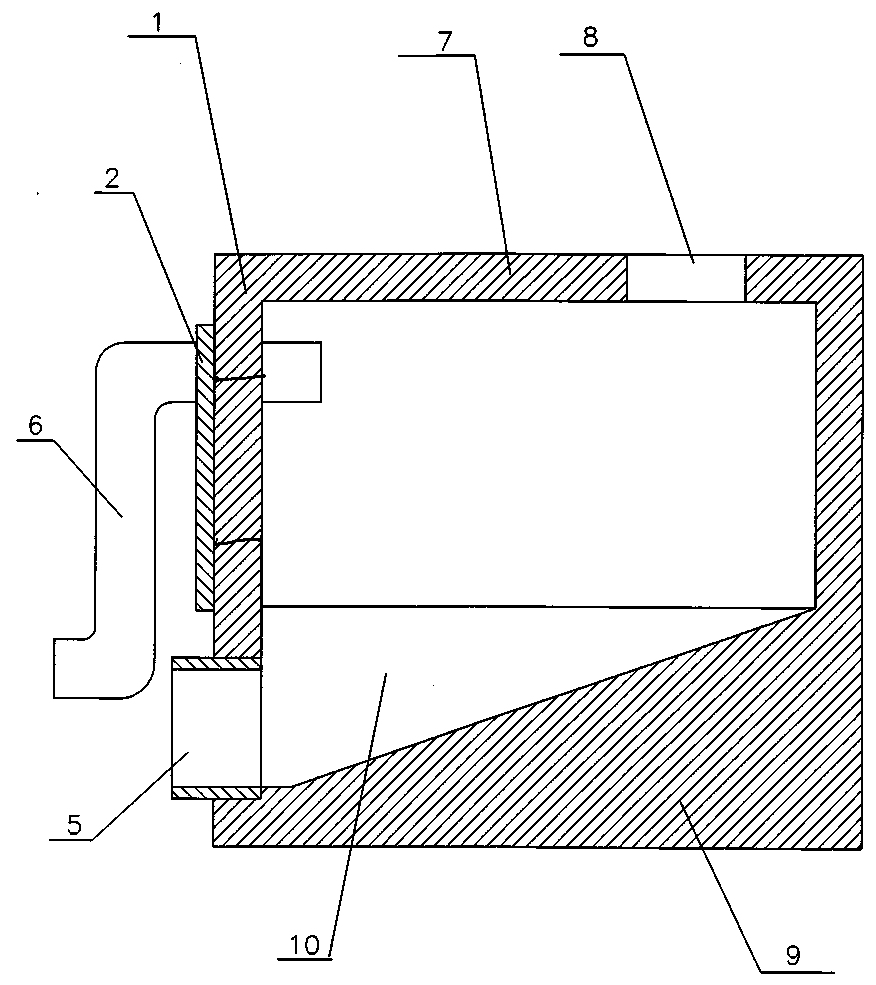

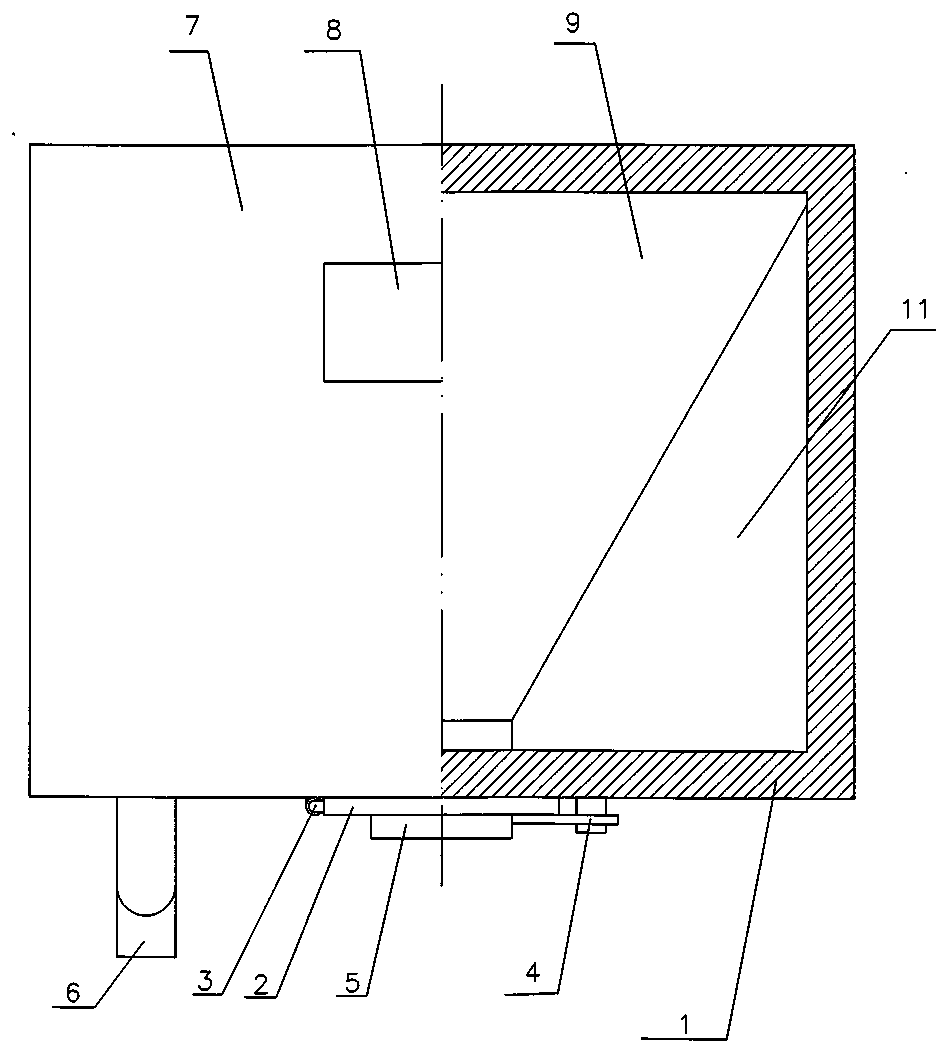

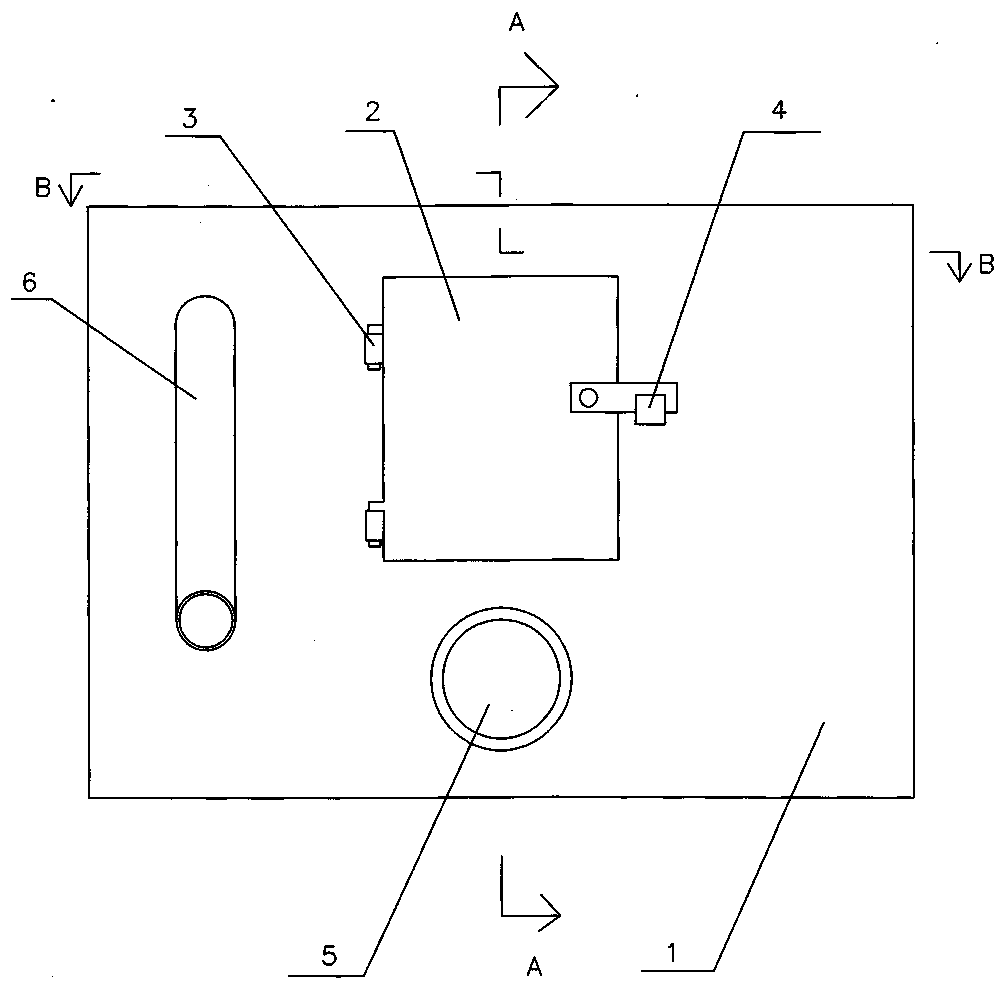

[0018] There is a door 2 in the middle of the front wall 1, and the door 2 is connected with the front wall 1 through a hinge 3. When the door 2 is closed, it is stuck on the front wall 1 by a door bolt 4. There is a crushing material pipe 5 on the front wall 1 directly below the door 2. The left part of the front wall 1 has a powder outlet pipe 6, and the upper wall 7 has a pulverized material inlet 8 at the rear, and the pulverized material inlet 8 matches the pulverizer outlet. Bottom surface is made up of bottom positive slope 9, bottom left slope 10, bottom right slope 11.

[0019] When in use, close the door 2, connect the crushed material inlet 8 with the pulverizer outlet, install a dust collector on the powder outlet pipe 6, connect the powder collection bag with the powder outlet pipe 6, and place the crushed material container on the pulverized material outlet pipe 5 below.

[0020] Start the pulverizer and the dust extractor, and the pulverized material enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com