Air adjustable dust collector

A technology of air conditioning and dust collectors, applied in air conditioning systems, space heating and ventilation, heating methods, etc., can solve the adverse effects of air quality and working environment, reduce heat exchange energy efficiency and power energy efficiency, and cannot effectively control harmful smoke and dust, etc. problems, to achieve the effect of low operation and maintenance costs, small investment, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

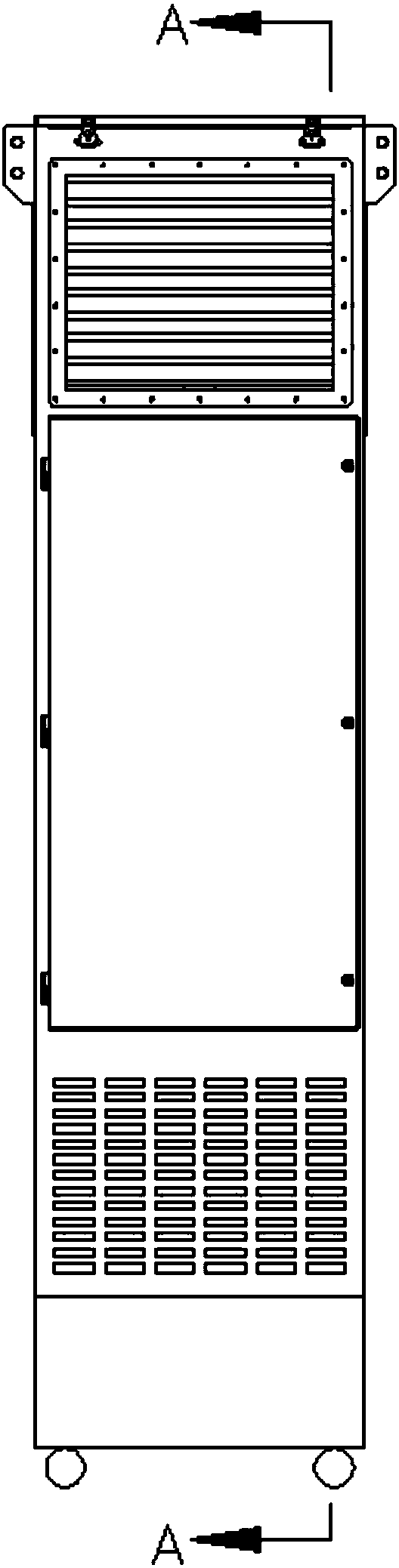

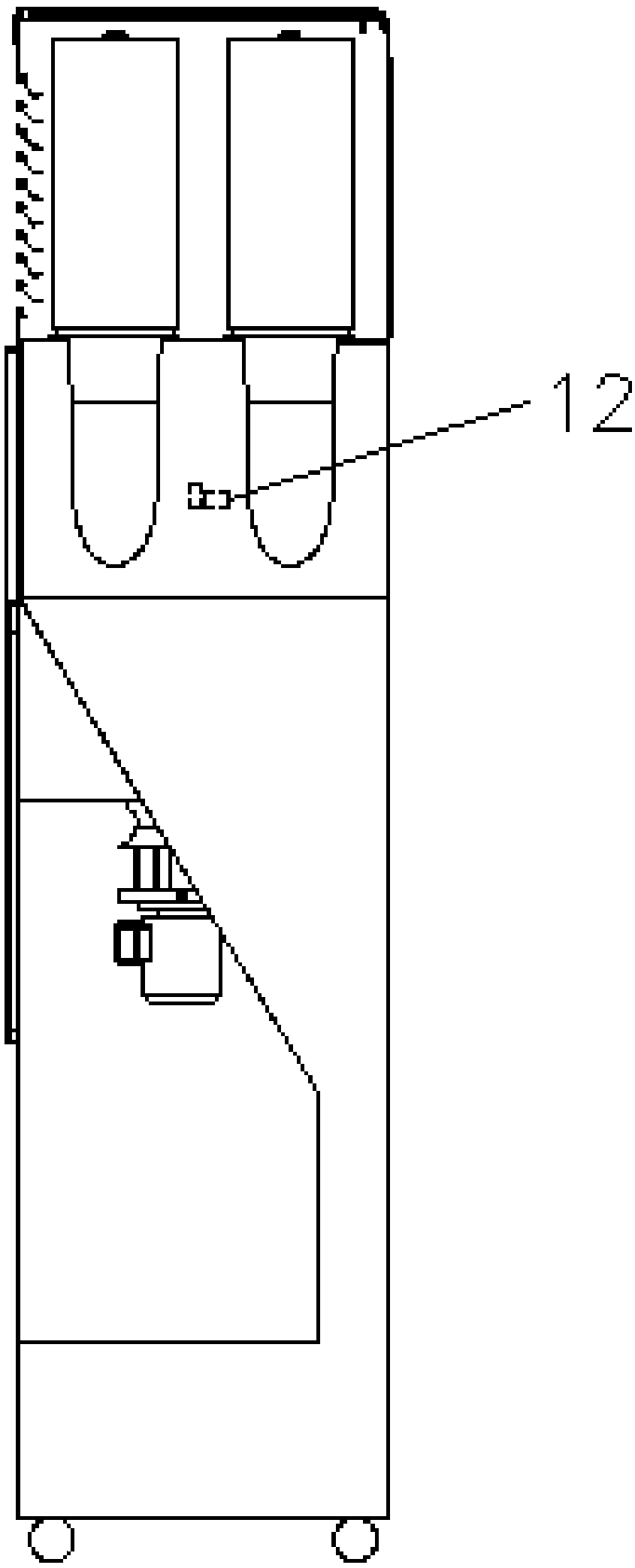

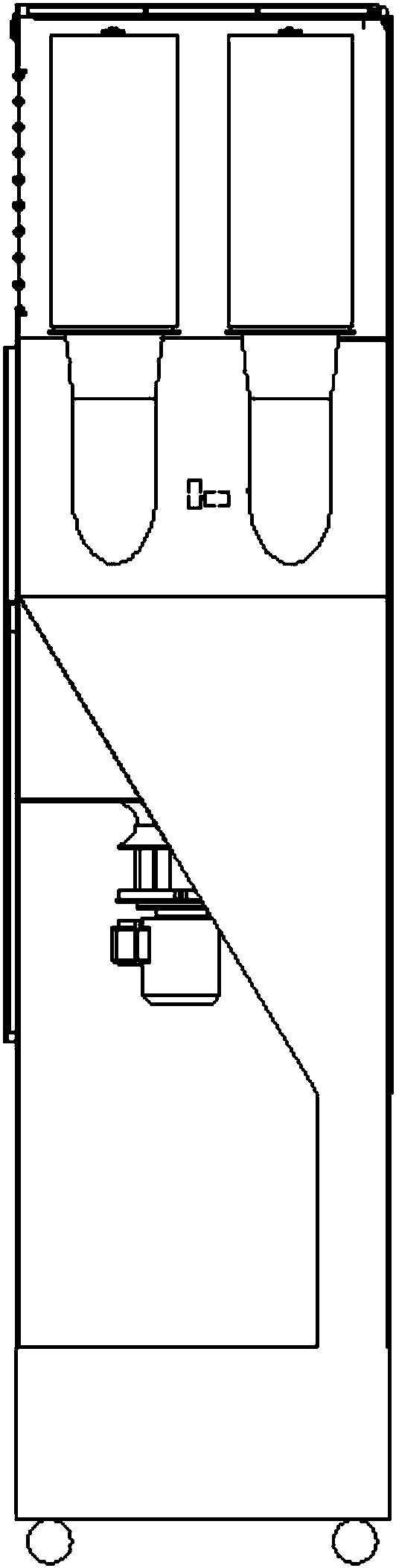

[0038] Below in conjunction with specific implementation methods and attached Figure 1-16 The present invention is described further:

[0039] The air conditioning dust collector includes a housing 1, the housing 1 includes a pollutant gas channel, a filter cartridge 3 and a clean gas channel, the upper part of the housing 1 is provided with an air inlet 2, and the lower part is provided with an air outlet 9; The filter cartridge 3 is arranged inside the air inlet 2 , the outlet of the filter cartridge 3 is connected to the clean gas channel, and the end of the clean gas channel is connected to the air supply port 9 . A blowback system and a fan 8 are arranged in the clean gas channel. A confluence injection pipe 4 is provided between the filter cartridge 3 and the clean gas channel, and the blowback system includes a blowback gas bag 5 and a blowback pipe 6, and the blowback pipe 6 is provided with a jet port 11, so The injection port 11 mentioned above is located below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com