A drainage type prefabricated pile convenient for construction and its construction method

A technology of prefabricated piles and pile bodies, applied in the fields of construction, geotechnical soil and pile foundation, can solve the problems of insufficient strength of bulk material piles and inability to drain water of rigid piles, and achieve the effect of increasing the area, speeding up drainage, and improving consolidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

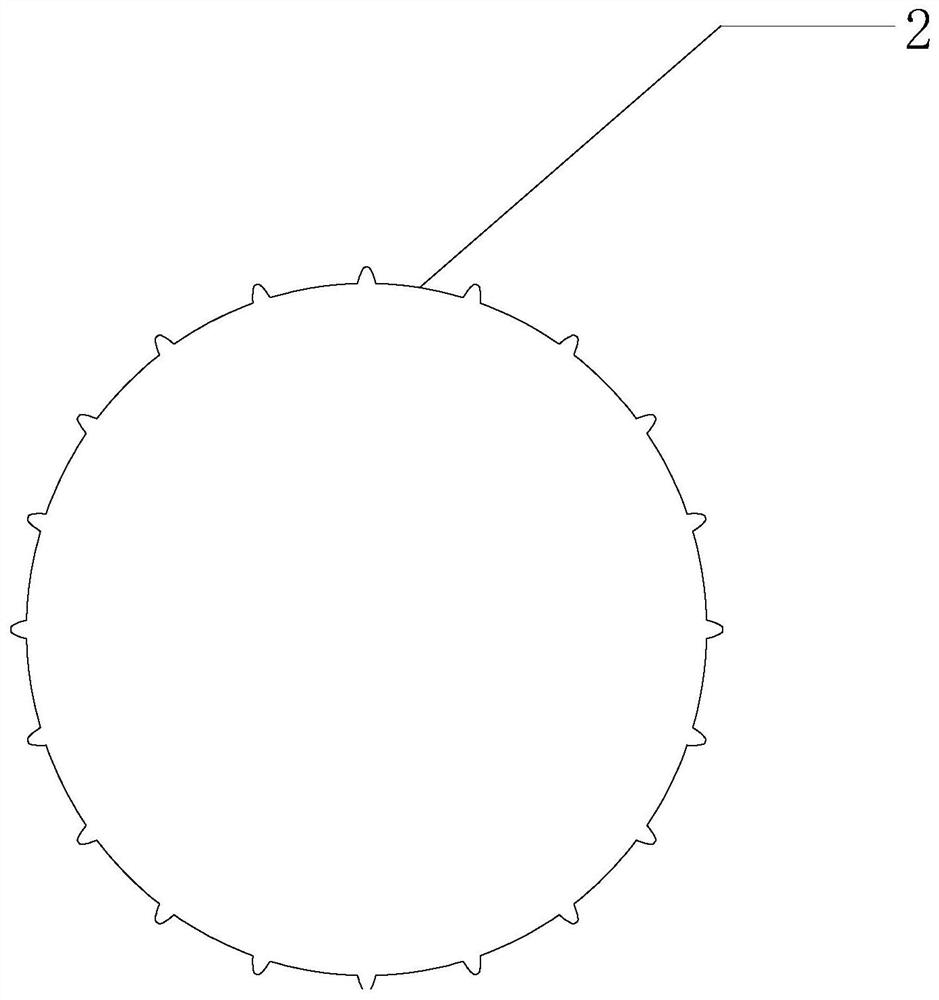

[0052]Embodiment 1: A self-draining prefabricated pile, comprising: an inner pile body 1 and an outer casing 2; the inner pile body 1 is prefabricated reinforced concrete, and its shape is circular.

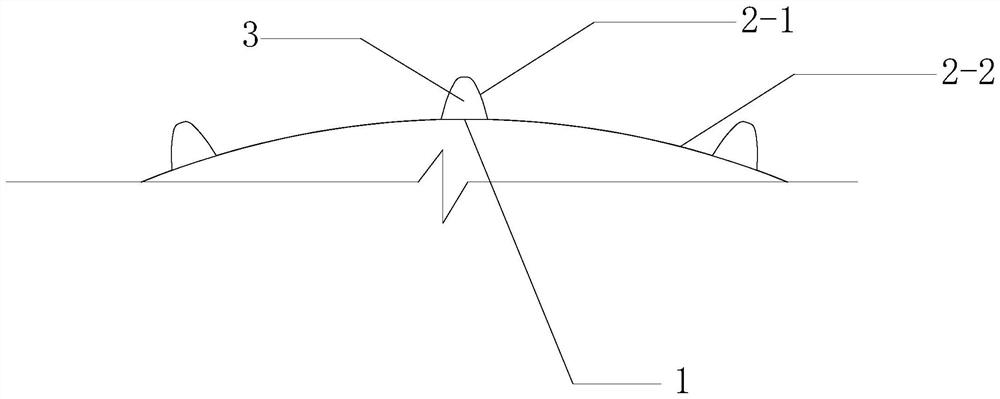

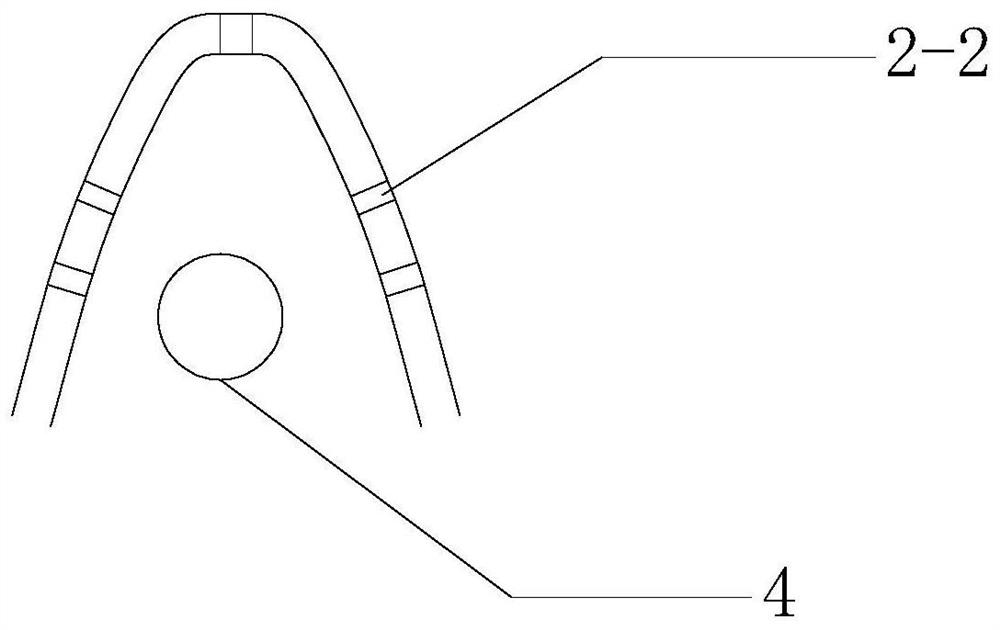

[0053] The outer casing 2 is divided into: a protruding part 2-1, a matching part 2-2, the matching part 2-2 is adapted to the shape of the inner pile body 1, and several vertically extending protrusions 2-1 are arranged on the outer casing 2 , the protrusion space 3 formed between the protrusion 2-1 of the outer casing 2 and the inner pile body 1 serves as a vertical drainage channel.

[0054] A number of permeable holes 2-2 are provided on the protrusion 2-1, so as to allow moisture to penetrate into the protrusion space 3 from the protrusion 2-1;

[0055] The matching part 2-2 is in contact with the inner pile body 1 .

[0056] The protrusions 2-1 of the outer case 2 are uniformly arranged.

[0057] A water suction pipe 4 is arranged in each raised space, and the water sucti...

Embodiment 2

[0072] Embodiment two: if Figure 6-7 As shown, the inner pile body 1 is rectangular, and the outline of the outer casing 2 is also rectangular. The outer casing 2 is divided into: a protrusion 2-1, a matching portion 2-2, and the matching portion 2-2 is connected with the inner pile body 1. The shape is adapted, and the outer shell 2 is provided with several vertically extending protrusions 2-1, and the protrusion space 3 formed between the protrusions 2-1 of the outer shell 2 and the inner pile body 1 serves as a vertical drainage channel; the protrusions 2-1 is provided with a number of permeable holes 2-2, so that water can penetrate into the protrusion space 3 from the protrusion 2-1; the matching part 2-2 is in contact with the inner pile 1; the protrusion 2-1 of the outer shell 2 Set multiples on each side of the rectangle;

[0073] The bottom of the internal pile body 1 is provided with a pile point 5, and the bottom of the internal pile body 1 is provided with an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com