Device for preparing xylitol by integrating evaporation, crystallization and centrifugal separation and control method

A technology of centrifugal separation and control method, which is applied in the direction of crystallization separation, separation method, evaporation separation and crystallization, etc., can solve the problems of large energy consumption, low production efficiency, and low degree of automation, and achieve low energy consumption, high yield, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The multi-division system in this embodiment includes two sets of evaporators 5, each with a steaming capacity of 2 tons / hour. 8 vacuum crystallization kettles 6, volume 15m 3 / tower. 2 sets of overhead centrifuges 7, model XG-1250AT. The production capacity of the xylitol crystals of the device in this embodiment is 3 ton / hour to 4 ton / hour.

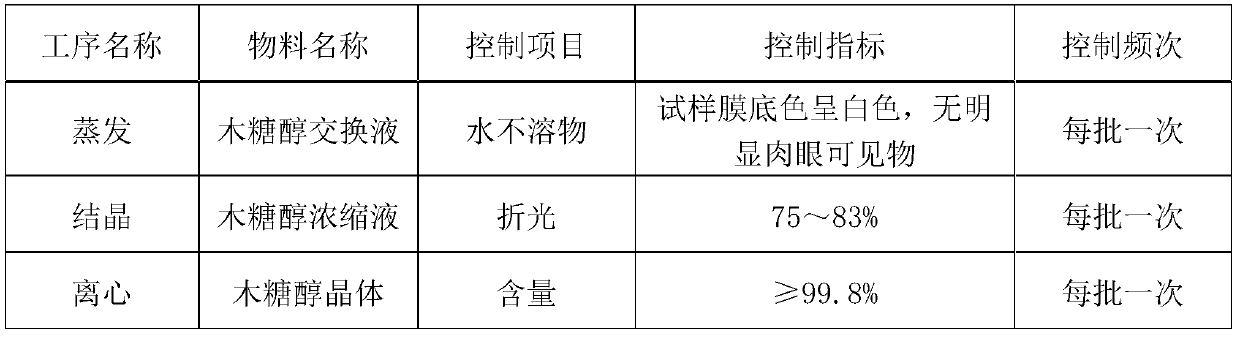

[0061] The present embodiment device prepares xylitol process and comprises:

[0062] First filter the xylitol exchange liquid, use a 0.45 micron pore size filter element to remove coarse particles, control the pressure difference from 0.1MPa to 0.4MPa, then change to a 0.22 micron pore size filter element for fine filtration, until there is no obvious visible matter to the naked eye. Concentrate by evaporation.

[0063]Turn on the vacuum pump of evaporator 5. After the vacuum degree of evaporator 5 reaches -0.08mpa, turn on the evaporator feed pump and evaporator return valve. 5, adjust the pressure difference and evaporate...

Embodiment 2

[0068] The multiple diversion system in the present embodiment comprises three groups of evaporators 5, each group of steaming water capacity is 3 tons / hour; 14 vacuum crystallization kettles 6, volume 20m 3 / set; 4 top-hanging centrifuges 7, model XG-1250AT. The production capacity of the xylitol crystals of the device in this embodiment is 6 ton / hour to 10 ton / hour.

[0069] The present embodiment device prepares xylitol process and comprises:

[0070] First filter the xylitol exchange liquid, use a 0.45 micron pore size filter element to remove coarse particles, control the pressure difference from 0.1MPa to 0.4MPa, then change to a 0.22 micron pore size filter element for fine filtration, until there is no obvious visible matter to the naked eye. Concentrate by evaporation.

[0071] Turn on the vacuum pump of evaporator 5. After the vacuum degree of evaporator 5 reaches -0.08mpa, turn on the evaporator feed pump and evaporator return valve. 5, adjust the pressure differ...

Embodiment 3

[0076] The xylitol exchange liquid first goes through coarse filtration and fine filtration to remove particulate impurities. During the coarse filtration process, a filter element with a pore size of 0.45 microns is used to filter the exchange liquid, and the pressure difference during filtration is controlled at 0.1MPa to 0.4MPa. The pore size filter element for fine filtration is The 0.22 micron pore size filter element filters the exchange liquid, and the pressure difference during filtration is 0.1MPa~0.4MPa. In this way, it can be ensured that while the large particle crystals are completely filtered during the filtration process, the xylitol mother liquor will not be lost by the filtration process, thereby causing losses.

[0077] Afterwards, the obtained xylitol exchange liquid is detected, and when the light transmittance reaches more than 95% and the pH value is between 5.0 and 7.5, the next step is performed to detect the filtering effect of the xylitol exchange liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com