A tea feeding process

A technology of tea and craftsmanship, applied in the field of tea feeding and feeding technology, can solve problems such as difficult to improve production efficiency, difficult to achieve balance, and affect tea processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

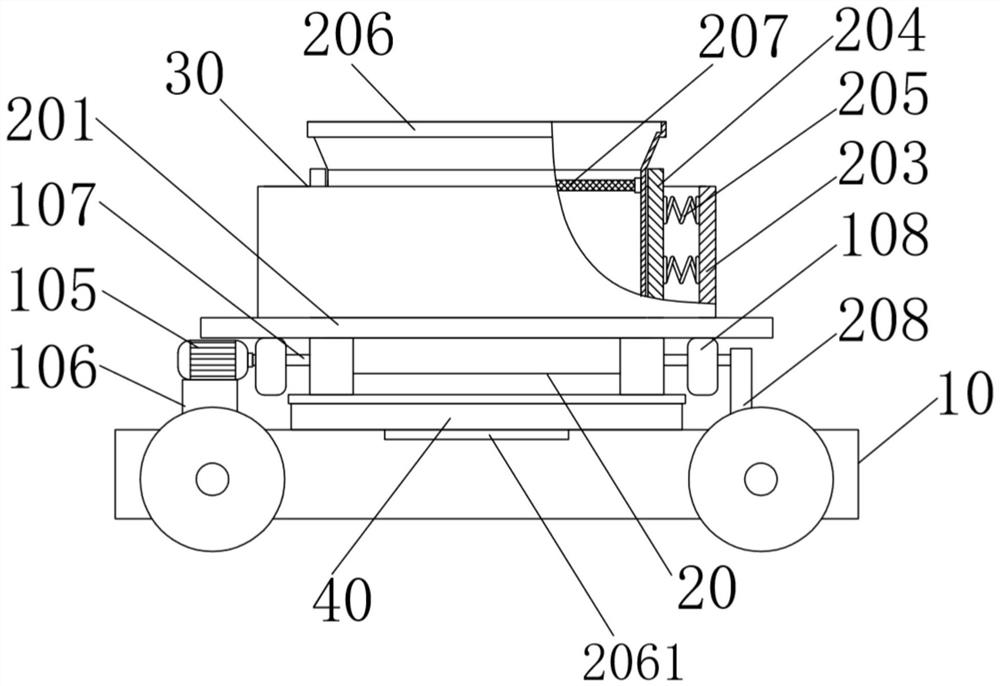

[0079] Such as Figure 1~8 As shown, the present invention provides a tea leaf feeding and feeding process, which includes the following steps:

[0080] Step 1. The feeding cart 1 is in place to receive materials:

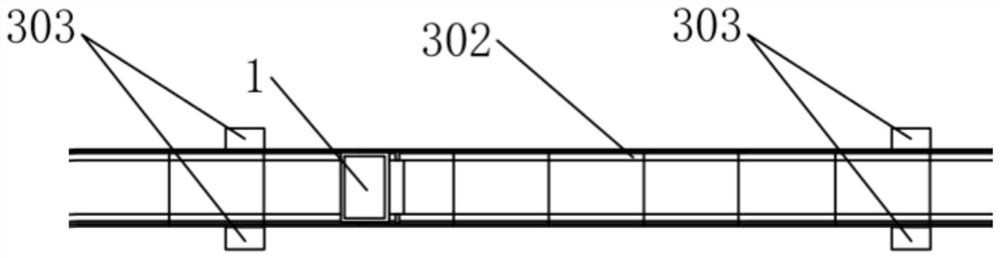

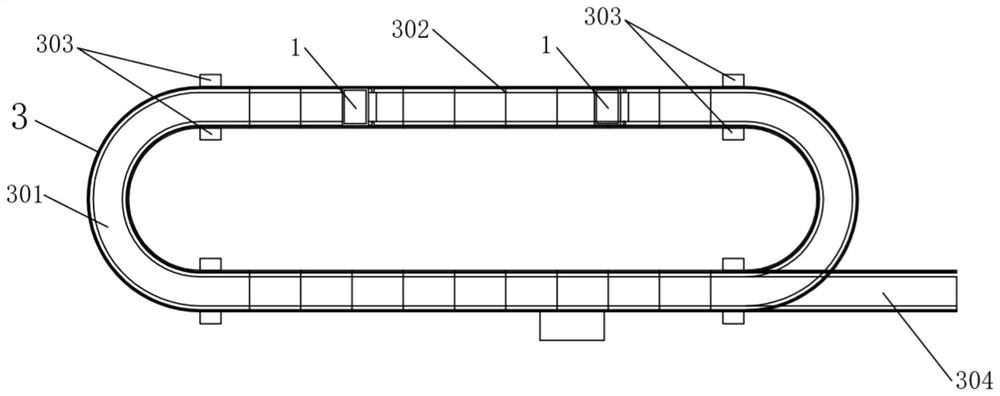

[0081] The feeding trolley 1 slides along the straight track 302 or the circular track 3 to the receiving position located below the end of the feeding belt 2, waiting to receive the to-be-kneading process (usually finishing, resurgence) transmitted along the feeding belt 2 Or after withering) tea leaves;

[0082] Step 2. Quantitative measurement and feeding:

[0083] The feeding belt 2 conveys the tea leaves into the feeding trolley 1 regularly and metering; considering that the feeding and feeding of tea belongs to small flow control, the error is large, and the accuracy is high; therefore, the feeding belt 2 adopts speed detection, high-precision weighing sensor detection and Integral algorithm and other methods are combined to realize the guarantee of measurement accu...

Embodiment 2

[0109] Based on the foregoing tea feeding and feeding process, the present invention also provides a specific embodiment of a tea feeding and feeding device, which includes at least one feeding trolley 1, and each feeding trolley 1 is equipped with a PLC; The feeding cart 1 is a straight track 302 or an annular track 3 for conveying tea leaves to multiple kneading machines; and a feeding device for loading tea into the feeding cart 1; the feeding cart 1 is arranged on the straight track 302 or the ring It runs on the track 3, and moves the loaded tea leaves to the corresponding position along the straight track 302 or the circular track 3 and completes the feeding of the kneading machine near this position. After the discharge is completed, the feeding trolley 1 follows the straight track 302 or the circular track 3 moves to a predetermined position, and the feeding trolley 1 is loaded with tea leaves through the feeding device.

[0110] Specifically, such as figure 1 As shown: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com