A hinged automatic drive unit and a folding support arm driven by a folding screw

An automatic drive and lead screw drive technology, applied in the aerospace field, can solve the problems of difficult antennas, small folding ratio, and limited deployment range, and achieve the effects of wide application range, improving folding ratio, and saving launch costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

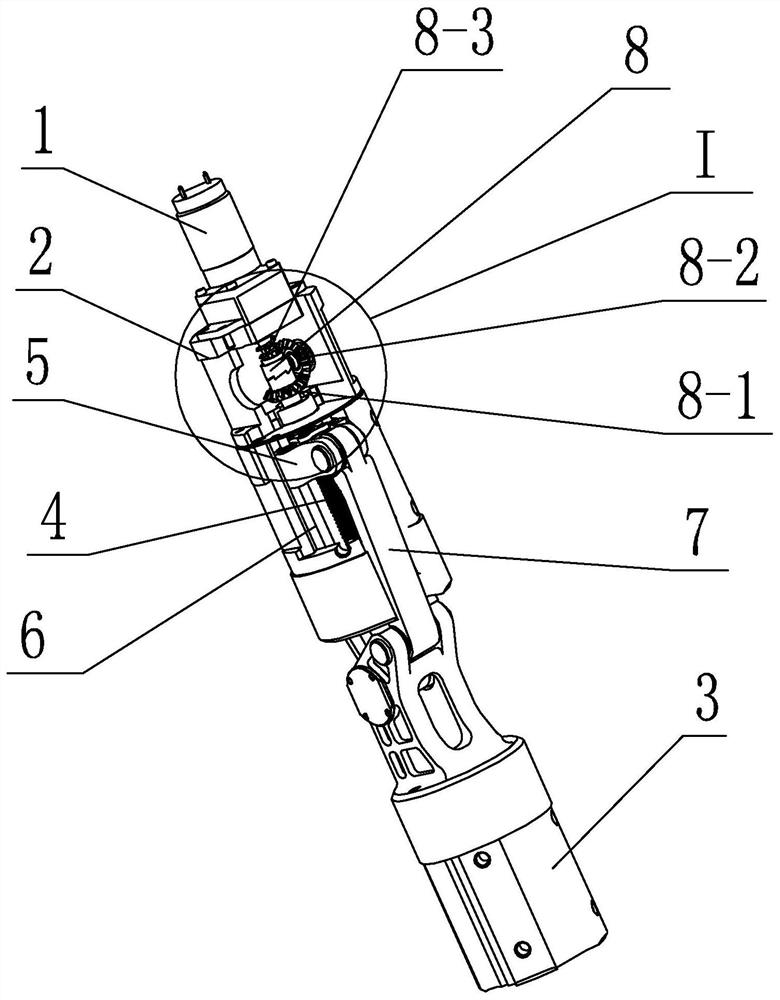

[0031] Embodiment 1: Combining figure 1 and figure 2 To illustrate this embodiment, an articulated automatic drive unit of this embodiment includes a motor 1 , a first connecting body 2 , a second connecting body 3 , a lead screw 4 , a nut 5 , a guide rod 6 and a connecting rod 7 ;

[0032] The first connecting body 2 and the second connecting body 3 are hinged. The first connecting body 2 is provided with a lead screw 4 and a guide rod 6. The axis of the lead screw 4 and the axis of the guide rod 6 are parallel to each other, and the lead screw 4 is driven by the motor 1 , the screw 4 is provided with a screw nut 5, the screw nut 5 is slidably arranged on the guide rod 6, one end of the connecting rod 7 is hinged with the screw nut 5, the other end of the connecting rod 7 is hinged with the second connecting body 3, and the connecting rod 7 The axis hinged with the second connecting body 3 and the axis where the first connecting body 2 is hinged with the second connecting b...

specific Embodiment approach 2

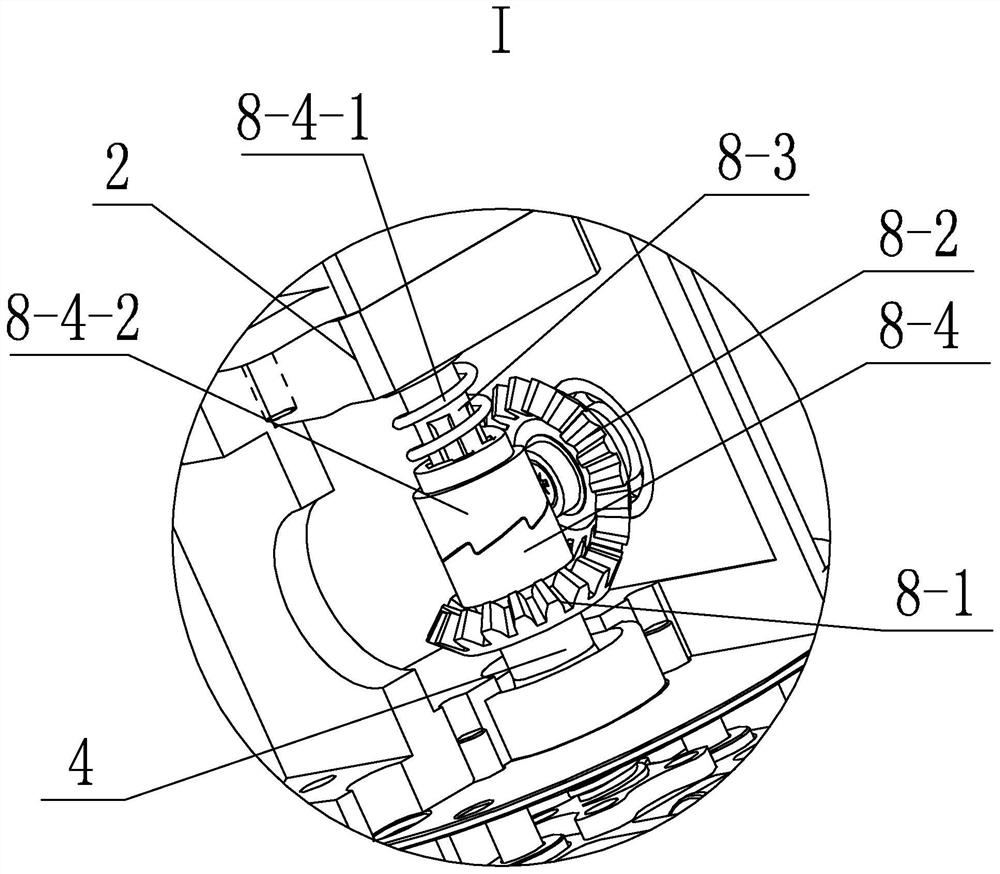

[0034] Specific implementation mode 2: Combining figure 1 and figure 2 To illustrate this embodiment, a manual drive device 8 is further provided between the lead screw 4 and the shaft of the motor 1 in this embodiment. The manual drive device 8 includes a first bevel gear 8-1, a second bevel gear 8-2, and a transmission shaft. 8-3 and one-way rotating mechanism 8-4;

[0035] The transmission shaft 8-3 is fixed on the shaft of the motor 1, a one-way rotation mechanism 8-4 is arranged between the end of the transmission shaft 8-3 and the end of the lead screw 4, and the lead screw 4 is fixed with a first bevel gear 8-1. The second bevel gear 8-2 is arranged on the first connecting body 2 through the rotating shaft, and the first bevel gear 8-1 and the second bevel gear 8-2 mesh with each other.

[0036] Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific implementation three: combination figure 2 To illustrate this embodiment, the one-way rotation mechanism 8-4 of this embodiment includes a first compression spring 8-4-1 and two ratchet toothed sleeves 8-4-2;

[0038] One of the ratchet toothed sleeves 8-4-2 is slidably arranged on the transmission shaft 8-3 and can rotate together with the transmission shaft 8-3. The first compression spring 8-4-1 is sleeved on the transmission shaft 8-3 and the two The ends respectively press on the first connecting body 2 and the end of one of the ratchet toothed sleeves 8-4-2, and the other ratchet toothed sleeve 8-4-2 is fixed on the end of the lead screw 4, The ratchet teeth on the two ratchet toothed sleeves 8-4-2 cooperate with each other under the action of the first compression spring 8-4-1.

[0039] The transmission shaft 8-3 can be a spline shaft, or a square shaft or other shaft that can generate torque to one of the ratchet toothed sleeves 8-4-2, and can make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com