Hull construction new process and new structure and application thereof

A new structure and new process technology, applied in ship construction, hull, hull parts, etc., can solve the problems of long construction period, self-heavy weight, reduced utilization rate, etc., and achieve the effect of low shipbuilding cost, long service life and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

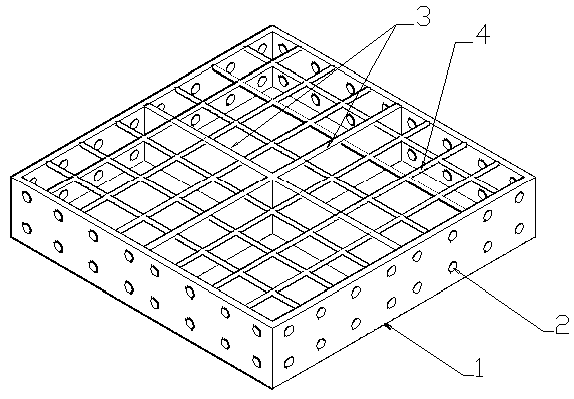

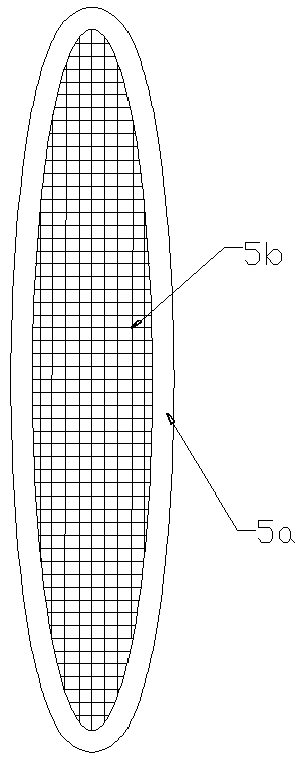

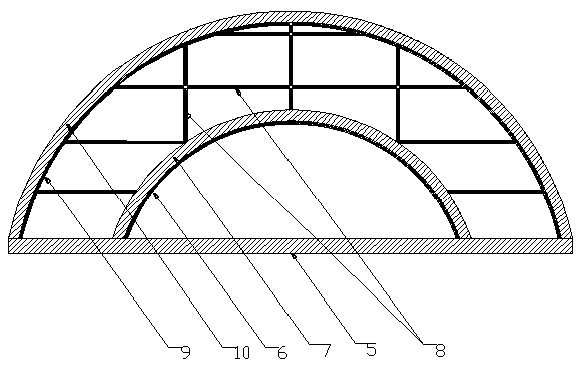

[0017] figure 1 Among them, the integral hull of the ship is an internal and external multiple shell structure, and the shells are connected by cabin partitions 8 to form an overall hull structure. Complete the construction of the complete inner shell 7 and the complete outer shell 10 of the ship on the inner shell pneumatic mold 6 and the outer shell pneumatic mold 9 of the ship's shell plate; Built on the overall deck 5, the hull after its preliminary construction is a floating body with the deck on the bottom and the bottom above; It turns over as a whole in the water so that the deck is on the top and the bottom of the ship is on the bottom. The entire hull avoids the use of integral heavy components, and the construction of its shell adopts the process of multi-point hoisting shell plate assembly by drone, so as to achieve the purpose of improving efficiency and shortening the construction period. The integral deck 5 of the ship is a floating body, and is anchored on ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com