Glue supply device used for continuous, stable and uniform glue coating and glue liquid coating method

A glue supply device and glue coating technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of discontinuous and stable pressure and the inability to achieve a stable and uniform coating effect, so as to achieve stable and uniform thickness and avoid Effect of corrugated coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 1 Embodiment approach

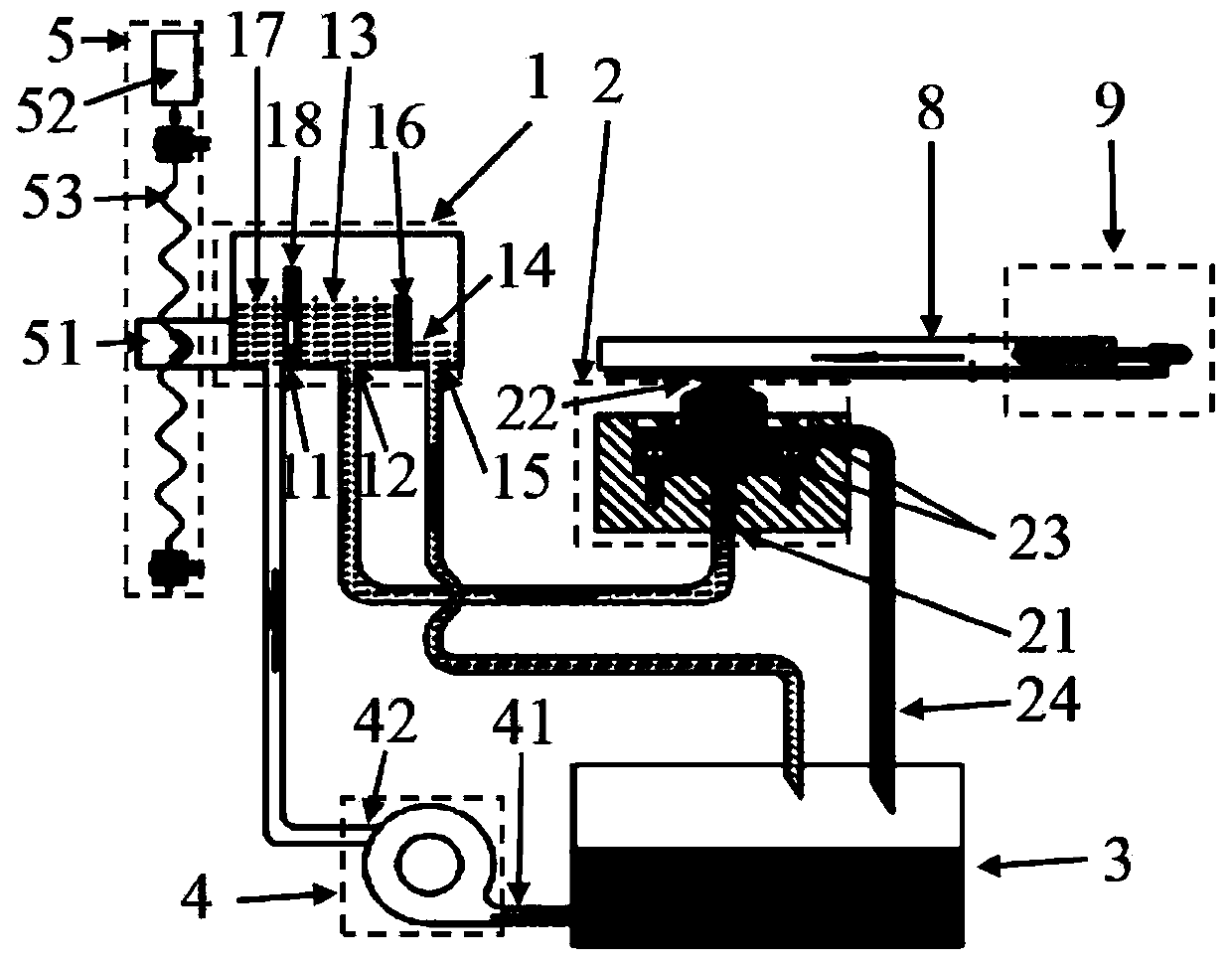

[0039] An embodiment of the glue supply device is as figure 2 As shown, the glue supply device includes a glue supply container (1), a glue spraying device (2), a low glue storage container (3), a liquid delivery device (4), a lifting device (5), a low glue storage container storage table ( 6), anti-vibration device (7). The glue supply container (1) includes the glue inlet (11), the glue outlet (12), the glue supply area (13), the overflow glue area (14), the overflow glue opening (15), the partition a (16), the buffer area (17), partition b (18), the glue inlet (11) is located in the buffer zone (17), the glue outlet (12) is located in the glue supply area (13), and the glue overflow port (15) is located in the glue overflow area ( 14), the glue supply area (13) and the overflow glue area (14) are separated by the partition a (16), the buffer zone (17) and the glue supply area (13) are separated by the partition b (18), the partition b ( 18) is higher than the partition a...

Embodiment 2

[0041] Embodiment 2 An embodiment of the meniscus gluing equipment of the present invention

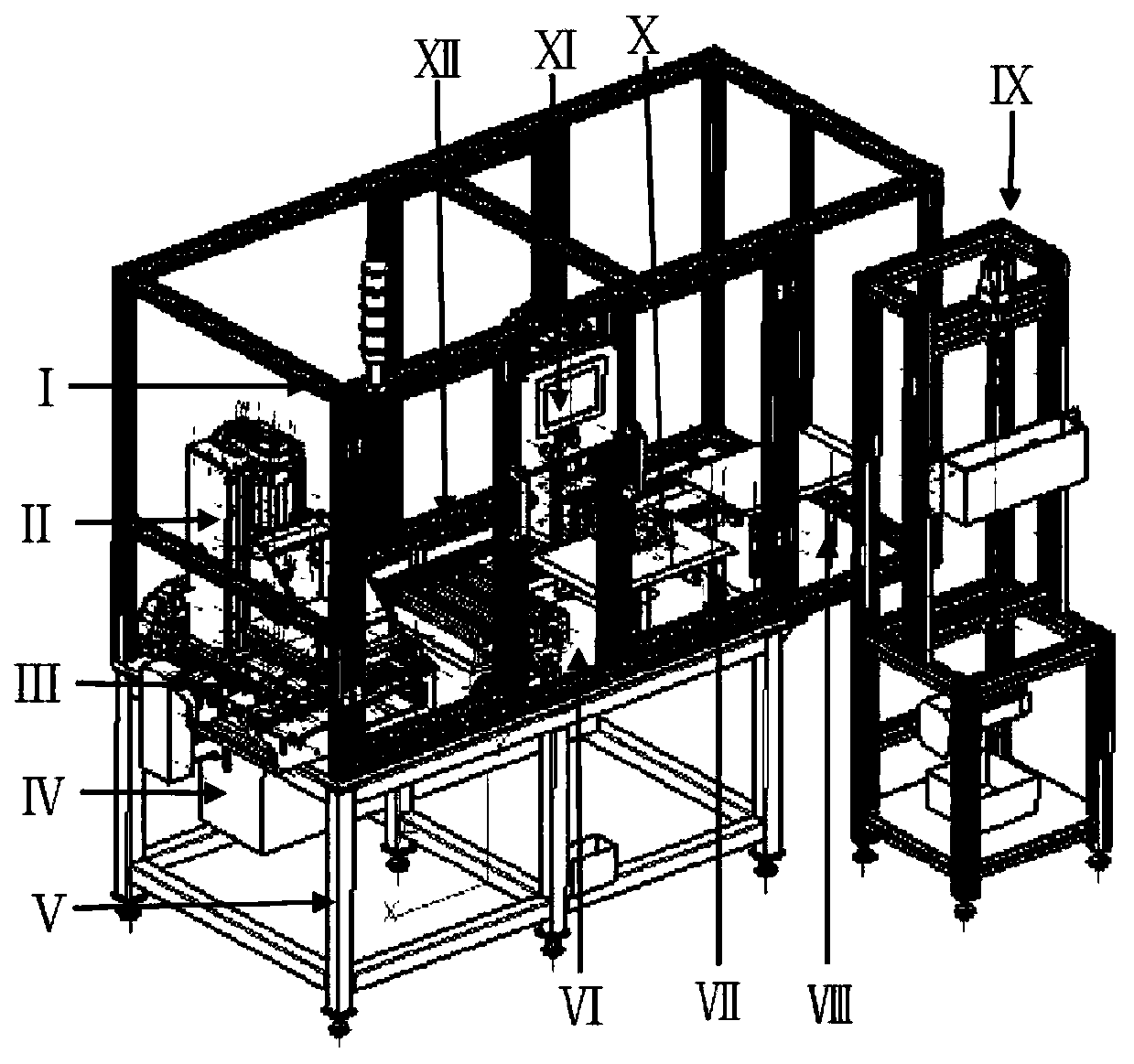

[0042] An embodiment of the meniscus gluing equipment for continuous, stable and uniform gluing is as follows: image 3 shown.

[0043] This gluing equipment includes equipment dust cover (Ⅰ), coating film element suction mechanical arm (II), coating film element positioning and loading table (Ⅲ), PLC control cabinet (IV), equipment support (Ⅴ), equipment support table (Ⅵ), product turning transition frame (Ⅶ), product turning unloading table (Ⅷ), glue supply device (Ⅸ), product turning manipulator (Ⅹ), central control panel (Ⅺ), linear motor drive guide rail (Ⅻ). Among them, the glue supply device is as described in Example 1, including a glue supply container (1), a glue spraying device (2), a low-level glue storage container (3), a liquid delivery device (4), a lifting device (5), a low-level glue storage Glue container storage table (6), anti-vibration device (7). Coating compo...

Embodiment 3

[0045] Embodiment 3 The influence of the position of the glue supply container on the state of glue application among the present invention

[0046] Such as Figure 4 As shown, suppose that in the connecting device formed by the glue supply container (1) and the glue spraying device (2), the vertical distance between the glue spraying port and the lowest point of the connecting device is h 22 , when the glue supply container is in different positions A, B, and C, the vertical distances between it and the lowest point of the connector are h A 、h B 、h C . When the glue supply container is higher than the glue spraying device in the vertical direction, that is h A > h 22 , the pressure difference generated by the height difference of the liquid level on the lowest point of the connector will promote the glue liquid to flow to the glue spraying device. When the positions of the glue supply container and the glue spraying device are unchanged, the pressure difference remains c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com