Preparation method of PD/C catalyst for one-step synthesis of alkylcyclohexylcyclohexanone liquid crystal intermediates

A catalyst and alkyl ring technology, applied in the field of industrial catalyst preparation, can solve the problems of easy deactivation of the catalyst and low yield of the target product, and achieve the effects of good dispersibility, simplified operation and strong surface basicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

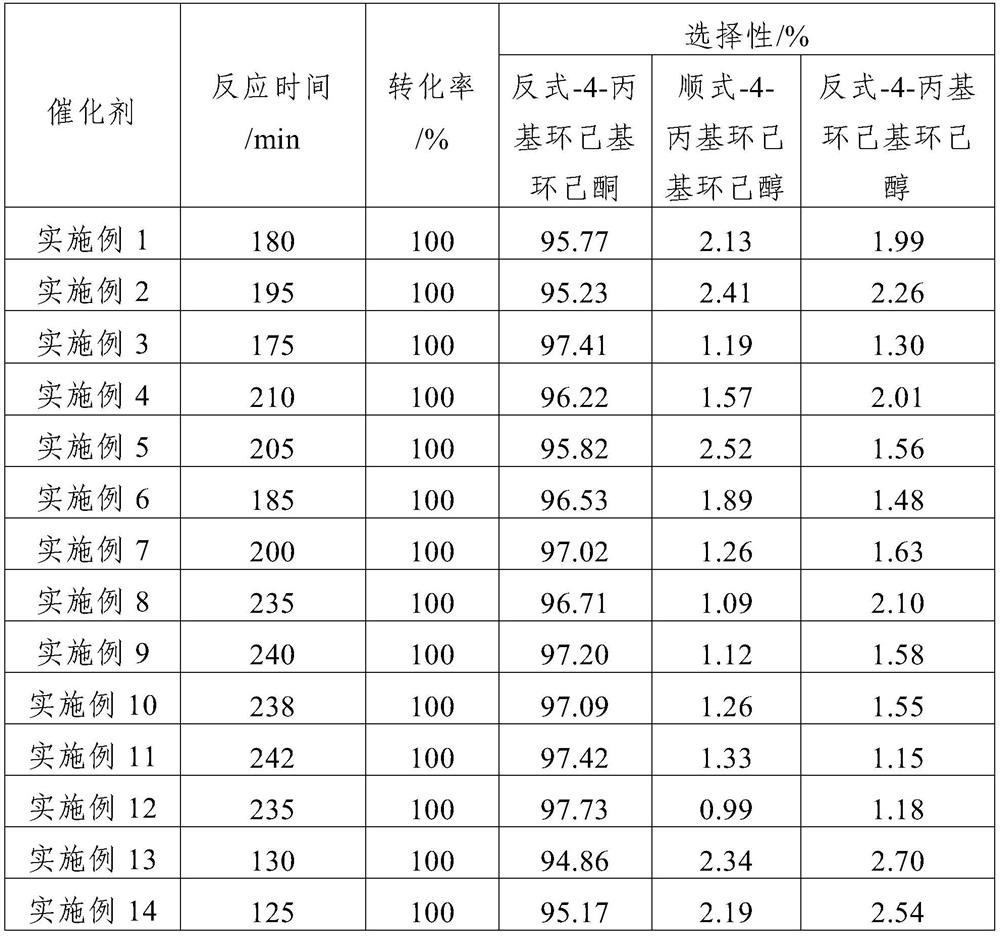

Examples

Embodiment 1

[0027] The catalyst of this embodiment comprises Ti-doped modified activated carbon, active component Pd and auxiliary agents, and the auxiliary agents are Zn and Sn; the mass percentage of Pd in the catalyst is 5%, and the mass percentage of Zn is 1.0%, and the mass percentage of Sn is 0.5%.

[0028] The preparation method of catalyst comprises:

[0029] Step 1. Activated carbon pretreatment: Dissolve 35.55g of butyl titanate in a mixed solution of 365mL of absolute ethanol, 80mL of acetylacetone and 20mL of nitric acid, add 95g of activated carbon, stir for 30min, evaporate the solvent to dryness, and age at 25°C for 24h. N at 800°C 2 Protective treatment for 30 minutes to obtain Ti-doped modified activated carbon;

[0030]Step 2, Pd precursor preparation: measure the H2O with a Pd mass concentration of 0.05g / mL 2 PdCl 4 Solution 100mL, add 200mL disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution with a concentration of 0.2mol / L and a pH of 6, then...

Embodiment 2

[0034] The catalyst of this embodiment comprises Ti-doped modified activated carbon, active component Pd and auxiliary agents, and the auxiliary agents are Zn and Sn; the mass percentage of Pd in the catalyst is 5%, and the mass percentage of Zn is 0.3%, and the mass percentage of Sn is 0.05%.

[0035] The preparation method of catalyst comprises:

[0036] Step 1. Activated carbon pretreatment: Dissolve 35.55g of butyl titanate in a mixed solution of 365mL of absolute ethanol, 80mL of acetylacetone and 20mL of nitric acid, add 95g of activated carbon, stir for 30min, evaporate the solvent to dryness, and age at 25°C for 12h. N at 500°C 2 Protective treatment for 2h to obtain Ti-doped modified activated carbon;

[0037] Step 2, Pd precursor preparation: measure the H2O with a Pd mass concentration of 0.05g / mL 2 PdCl 4 Solution 100mL, add 200mL of disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution with a concentration of 0.2mol / L and a pH of 6.4, then ...

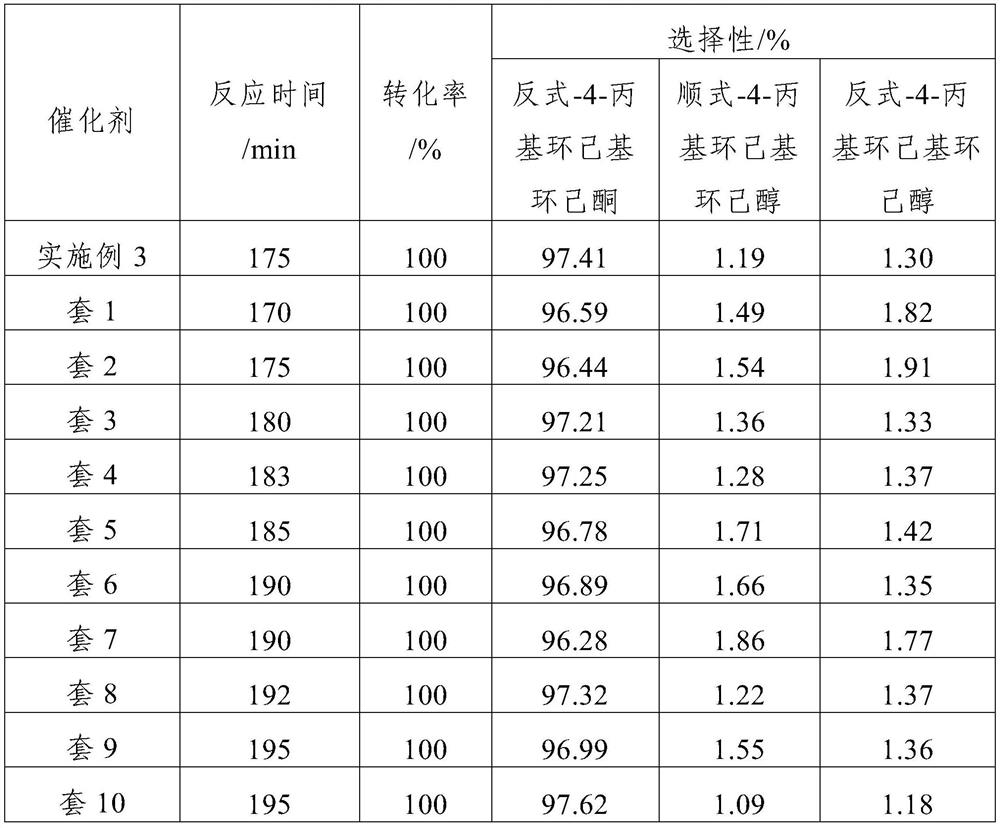

Embodiment 3

[0041] The catalyst of this embodiment comprises Ti-doped modified activated carbon, active component Pd and auxiliary agents, and the auxiliary agents are Zn and Sn; the mass percentage of Pd in the catalyst is 5%, and the mass percentage of Zn is 0.8%, and the mass percentage of Sn is 0.4%.

[0042] The preparation method of catalyst comprises:

[0043] Step 1. Activated carbon pretreatment: Dissolve 35.55g of butyl titanate in a mixed solution of 365mL of absolute ethanol, 80mL of acetylacetone and 20mL of nitric acid, add 95g of activated carbon, stir for 30min, evaporate the solvent to dryness, and age at 25°C for 20h. N at 700°C 2 Protective treatment for 30 minutes to obtain Ti-doped modified activated carbon;

[0044] Step 2, Pd precursor preparation: measure the H2O with a Pd mass concentration of 0.05g / mL 2 PdCl 4 Solution 100mL, add 200mL disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution with a concentration of 0.2mol / L and a pH of 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com