Knocking type rubber fruit sheller

A hulling machine and rubber technology, which is applied in the fields of shelling, solid separation, and separation of solids from solids by air flow. efficiency, improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific structure and working process of the present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

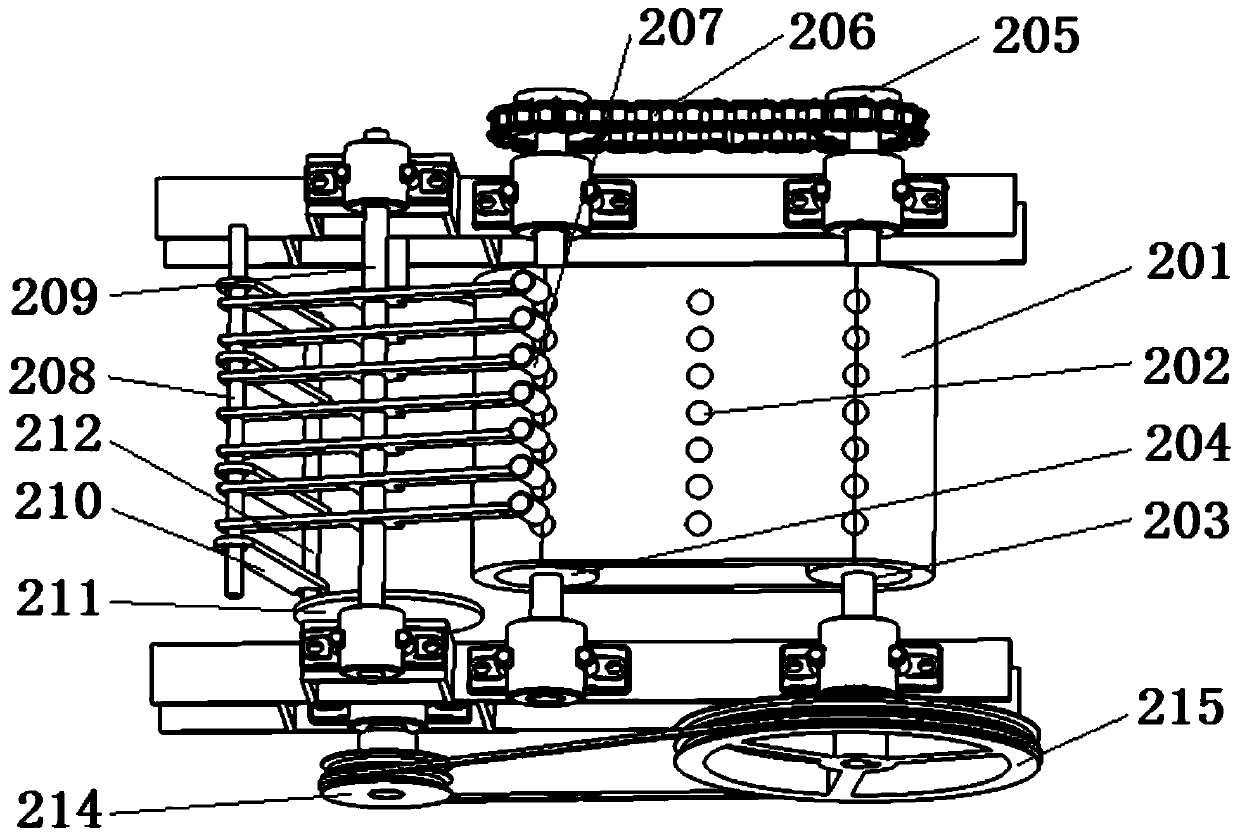

[0036] Figure 1A Schematic diagram of the overall structure with the protective cover removed for the percussion rubber fruit sheller, Figure 1B It is a schematic diagram of the overall structure of the percussion rubber fruit sheller. The percussion type rubber fruit sheller consists of a protective cover 9 placed on the frame from top to bottom, a feed hopper 1, a shell breaking unit 2, a separation unit 3, a sorting unit 4 and a power unit.

[0037] like Figure 5 In the schematic diagram of the rack structure shown, the rack 8 is composed of four rack columns 801 and a rack bottom layer 802 horizontally arranged from bottom to top, a middle layer 803 of the rack, a second layer 804 of the rack and an upper layer 805 of the rack A rectangular parallelepiped frame, wherein, the bottom layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com