Coil winding equipment with self-expansion type winding shaft

A reel and self-expanding technology, which is applied in the manufacture of coils, electrical components, inductors/transformers/magnets, etc., can solve the problems of high labor costs, small size of high-frequency transformers, and inability to effectively adapt to high-frequency transformer coil shafts, etc., to achieve The effect of improving processing efficiency and reducing product defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

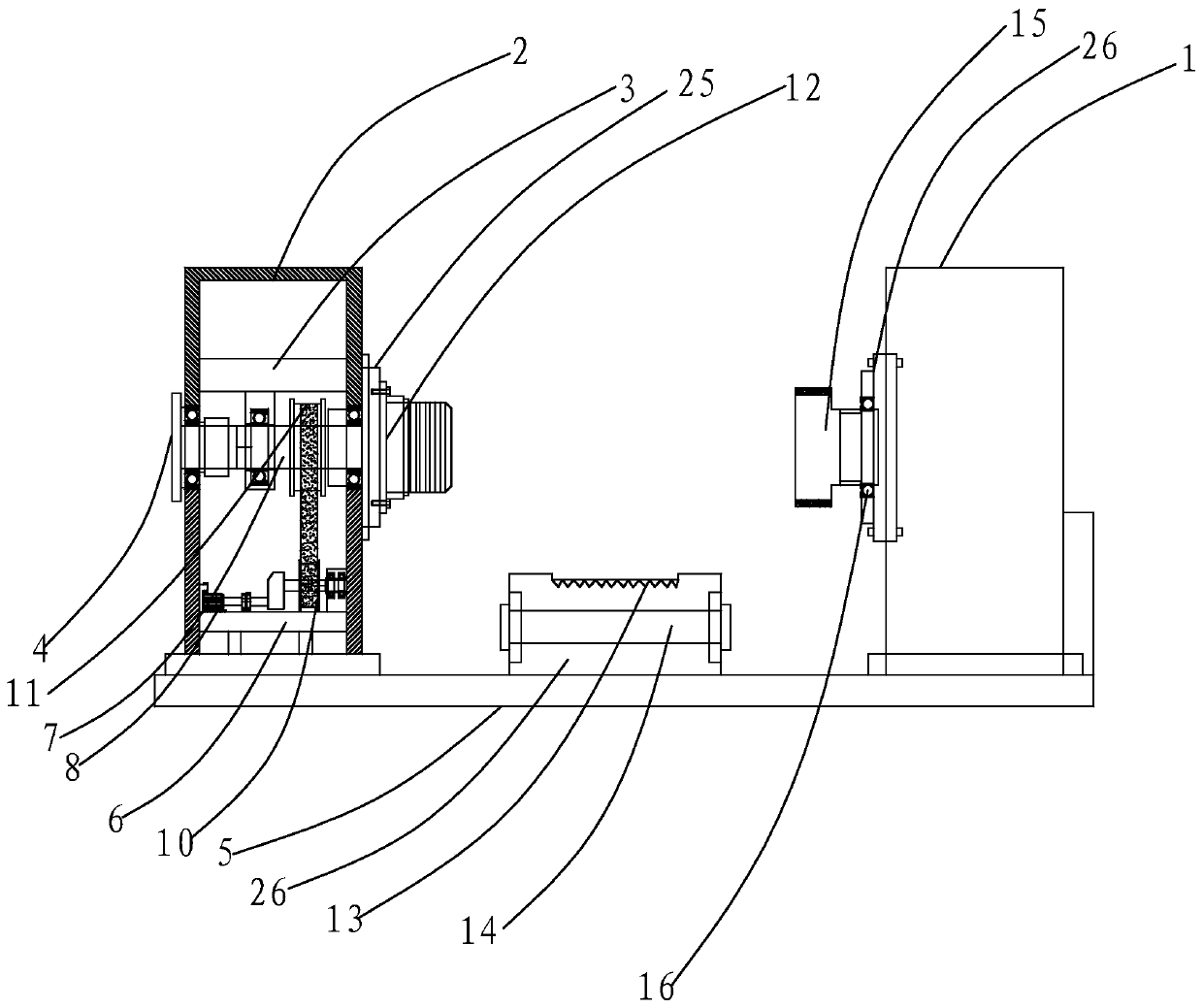

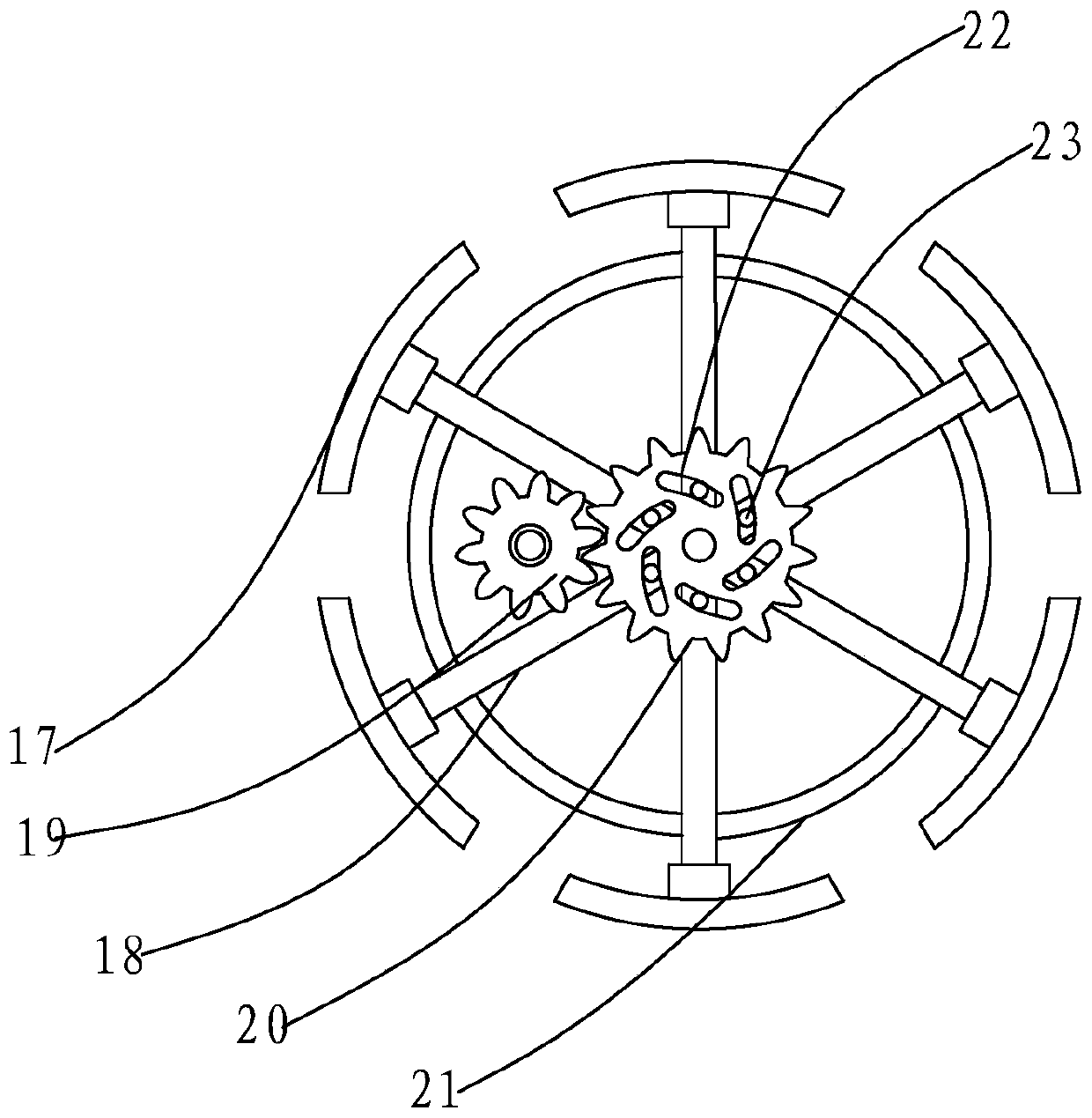

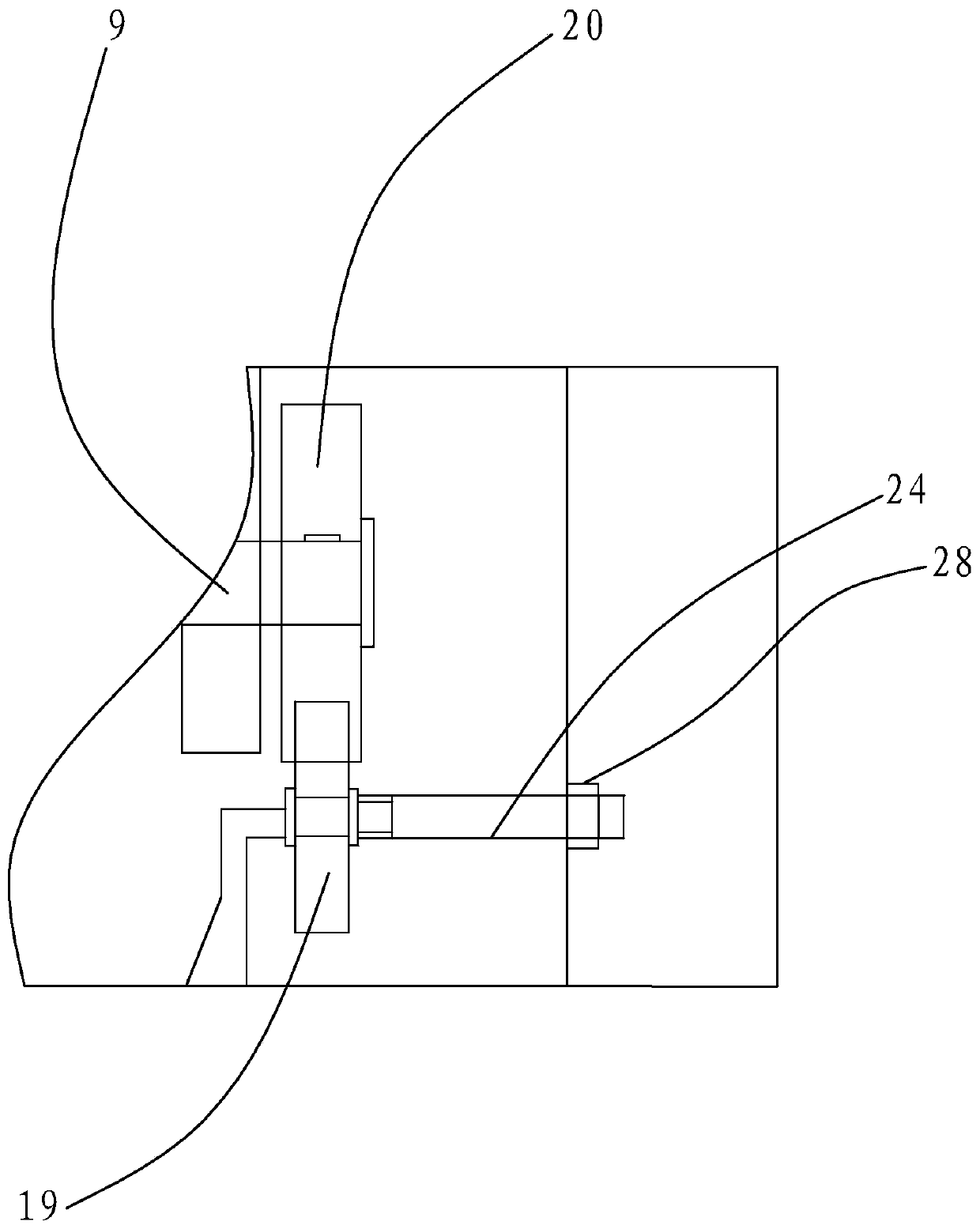

[0021] Such as figure 1 , 2 As shown in and 3, the present invention includes a working table 5, a power clamping table arranged on the working table 5, a fixed clamping table symmetrically arranged with the power clamping table 1, a reel device for fixing the coil shaft, and a power clamping table. The rotating seat 25 on the end surface of the clamping table, the driven seat 26 provided on the end surface of the fixed clamping table 1, and the toothed box 14 for cutting the insulating tape on the outer edge of the transformer. The toothed box 14 is provided in the middle of the worktable 5 and is empty The cavity is square, and a revolving shaft 14 is set up inside. The revolving shaft 14 is detachable and fixed. The revolving shaft 14 is interference-connected with a roll of insulating tape. The outlet 13 of the toothed box 27 has sharp teeth on one side and the other is smooth. Linear. The power clamping table includes a power clamping table outer shell 2, a fixed base fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com