Sampling tube and flue gas detecting device and flue assembly using the sampling tube

A technology for flue gas detection and sampling tubes, which is applied in the direction of sampling devices, measuring devices, exhaust gas devices, etc., and can solve problems such as low sampling accuracy and blockage of air intake holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

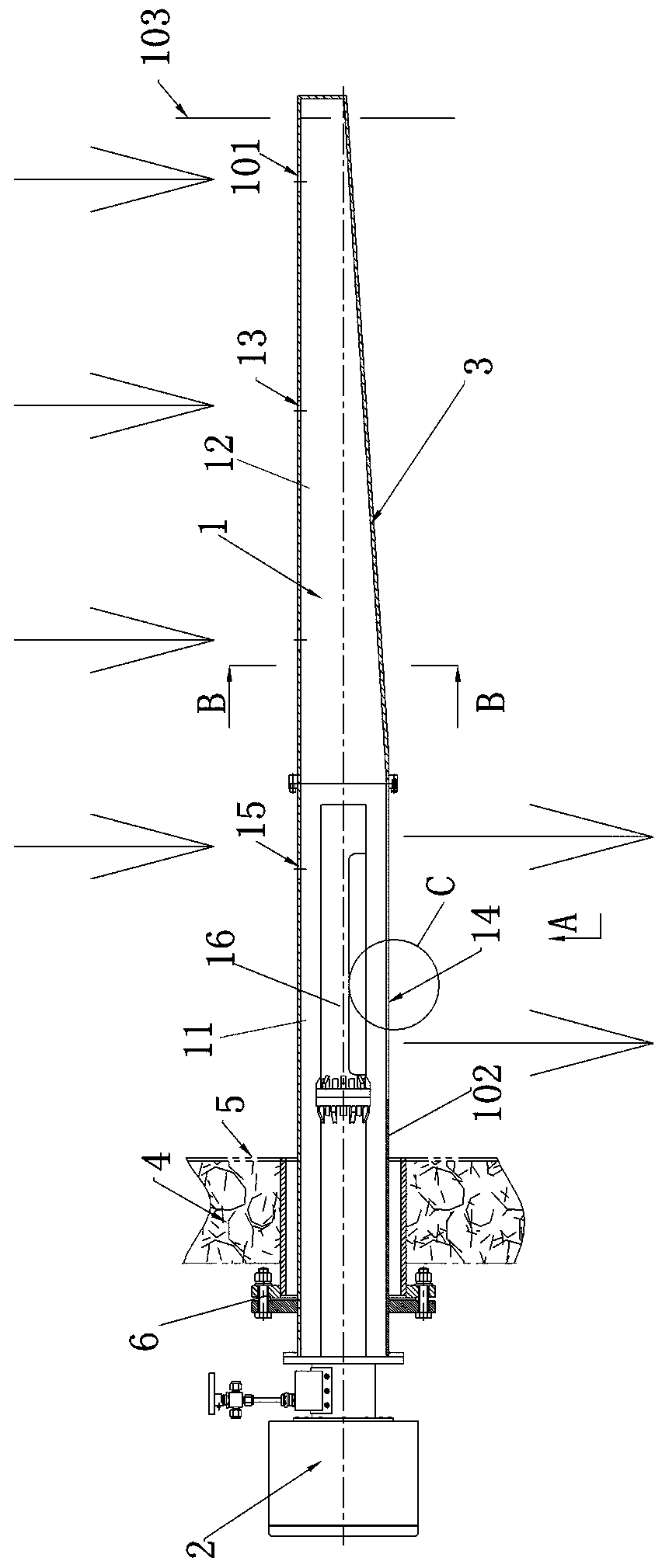

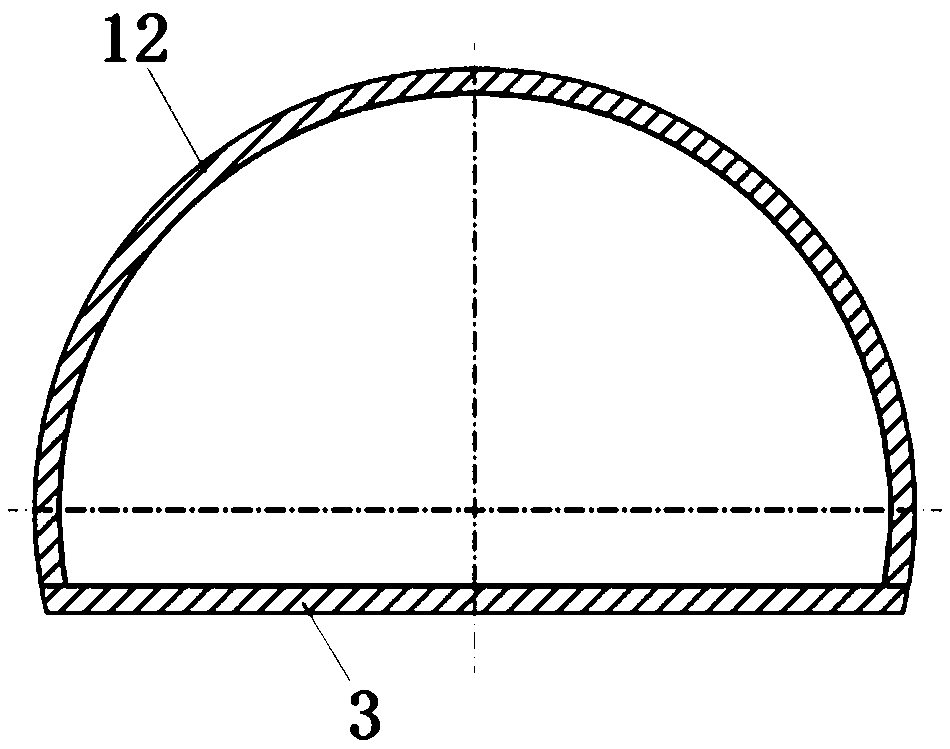

[0046] Such as Figure 1 to Figure 4 As shown, the smoke detection device includes a sampling tube for fixedly inserting into the flue along the radial direction of the flue, and the pipe body 1 of the sampling tube is provided with an installation structure for connecting with the wall 4 of the flue.

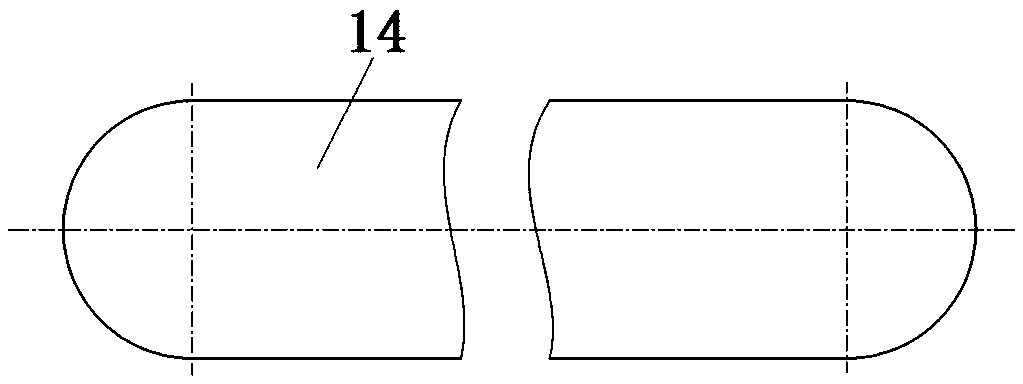

[0047] The inner end of the tube body 1 of the sampling tube for insertion into the flue is a sealed end, and when the tube body 1 is inserted into the corresponding flue, the sealed end crosses the centerline 103 of the flue. Moreover, corresponding to the flue gas flow direction of the flue, a windward side 101 and a leeward side 102 must be formed on the pipe body 1. Specifically, the front side of the pipe body 1 is the windward side 101 and the rear side for facing the direction of flue gas flow. The side is then the corresponding leeward side 102 . An air inlet is provided on the windward side wall of the pipe body 1. Correspondingly, an air outlet 14 is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com