Exhaust valve type carbon dioxide cracking pipe

A technology of carbon dioxide and exhaust pipes, which is applied in the direction of weapon accessories, blasting tubes, offensive equipment, etc., can solve the problems of reduced blasting power, insufficient inflation of cracked tubes, and low blasting power, so as to improve blasting power, high production efficiency, and blasting power huge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

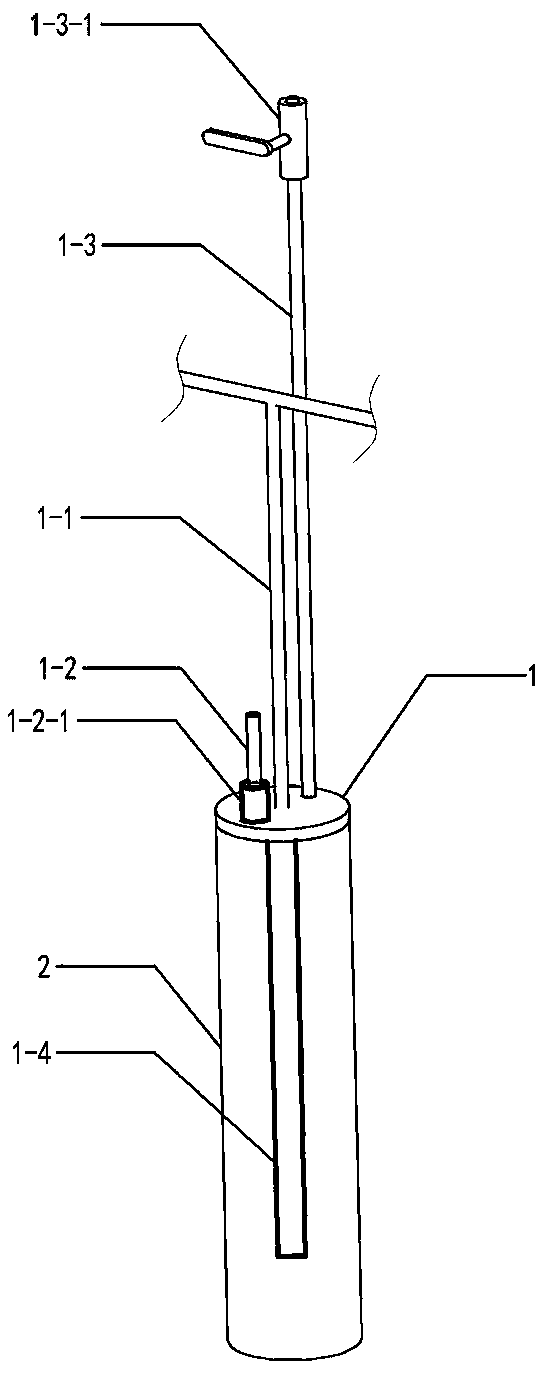

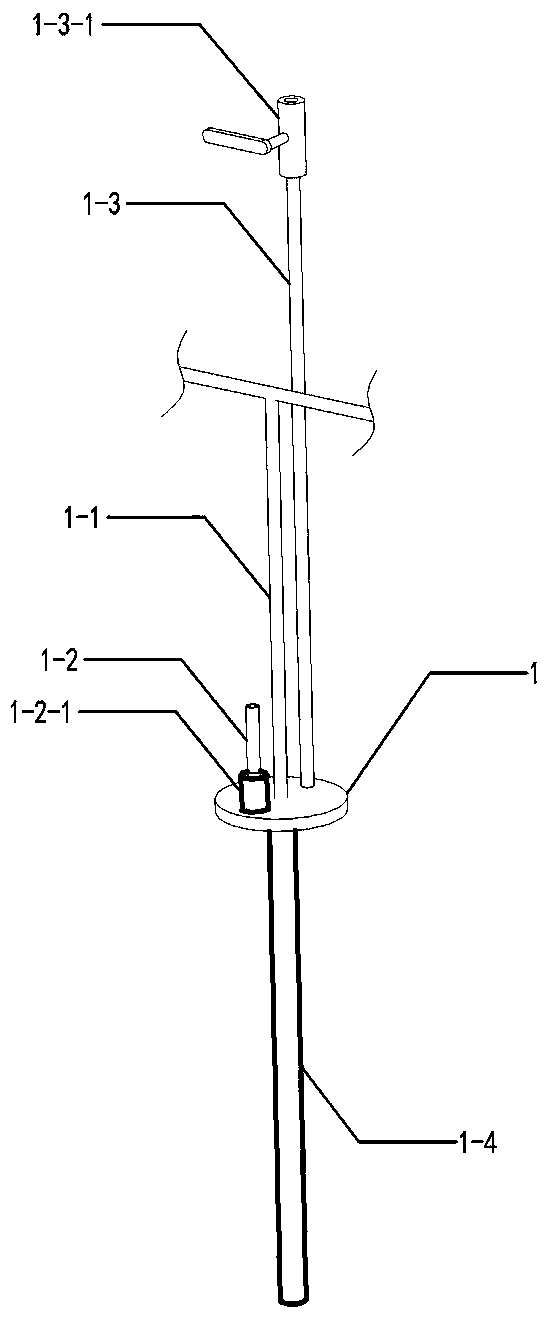

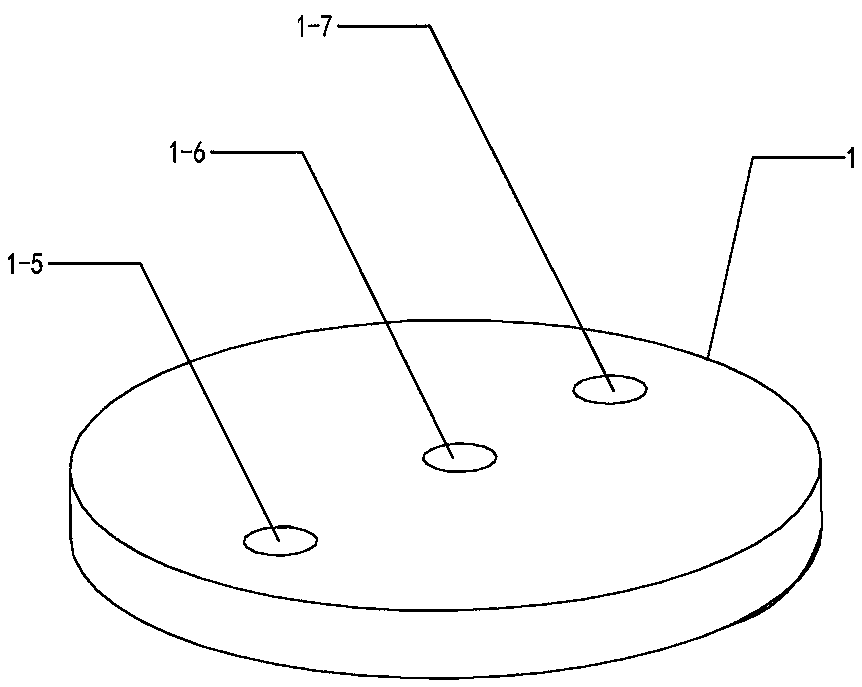

[0014] It can be seen from the content of the invention that an exhaust valve type carbon dioxide cracking tube is composed of a sealing plate 1, a tube body 2, an electronic fuze 1-1, an air intake pipe 1-2, an air intake check valve 1-2-1, an exhaust valve The air pipe 1-3, the exhaust pipe valve 1-3-1, and the heating pipe 1-4 are composed, and the sealing plate 1 is provided with an air inlet 1-5, a fuze hole 1-6, and an exhaust hole 1-7 ; The electronic fuze 1-1 passes through the fuze hole 1-6 and is connected to the explosive device 1-4; the air intake check valve 1-2-1 is installed in the air intake hole 1-5 and the air intake pipe 1-2 between; the lower end of the exhaust pipe 1-3 is welded to the mouth of the exhaust hole 1-7, and the exhaust pipe valve 1-3-1 is installed on the upper end of the exhaust pipe 1-3;

[0015] Sealing plate 1 described in the present invention refers to: the sealing plate of pipe body 2, its sealing effect; Draw the electronic fuze line ...

Embodiment 2

[0027] In order to realize the exhaust function of the present invention, an air intake pipe 1-2 and an exhaust pipe 1-3 are arranged on the sealing plate 1; the same end.

[0028] In order to realize the exhaust function of the cracking tube in the present invention, an exhaust pipe 1-3 is provided on the sealing plate 1 .

[0029] In order to realize rapid removal of impurities in the gas, the present invention designs the inlet pipe 1-2 and the exhaust pipe 1-3 at the same end of the exhaust-type cracking pipe.

[0030] The exhaust valve-type carbon dioxide cracking tube provided by the present invention is filled with liquid carbon dioxide inside and outside the tube of the exhaust-type cracking tube during use, and at the same time, a certain amount of gas is released by opening the valve 1-3-1 of the exhaust tube , after releasing for a certain period of time, close the exhaust pipe valve 1-3-1 to make it sealed, so that the gas in the exhaust-type cracking pipe is fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com