Design method of spoke bottom with high durability

A design method and durability technology, which is applied in the direction of wheels, spoke-plate wheels, rolling resistance optimization, etc., can solve the problems of reduced stiffness and durability of the spoke bottom, deformation of the spoke bottom, and reduced contact area, so as to improve durability Performance, the effect of avoiding design bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings and embodiments.

[0030] A method for designing a spoke bottom with high durability, characterized in that it comprises the following steps:

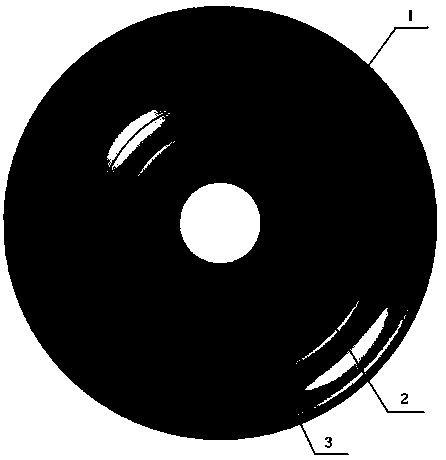

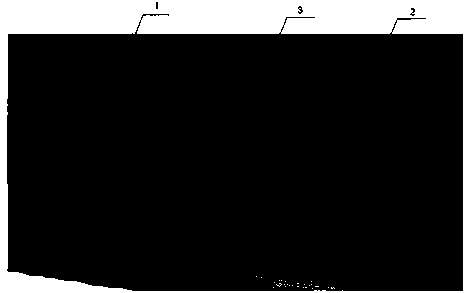

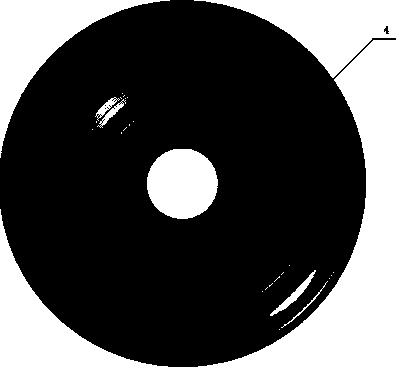

[0031] 1) The bottom of the spokes is composed of three annular planes, the outer mounting surface a1, the inner mounting surface b2 and the middle surface c3. The widths of the three sections a, b, and c are respectively 2-6mm, 20-35mm, and 2-6mm, adjacent to each other. There is a right-angle step transition between the planes, and there is a height difference between the three planes. The height difference between the outer installation surface a1 and the inner installation surface b2 is 0.3-0.9mm, and the height difference between the outer installation surface a1 and the middle surface c3 is 0.1- 0.4mm, the spokes are designed with equal material thickness;

[0032] 2) Design f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com