Farming and stockbreeding waste fuel forming machine

A waste and forming machine technology, applied in the direction of material forming presses, presses, grain processing, etc., can solve the problems of single function, increased labor intensity of workers, low work efficiency, etc., and achieve high degree of automation and compression molding effect Good, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

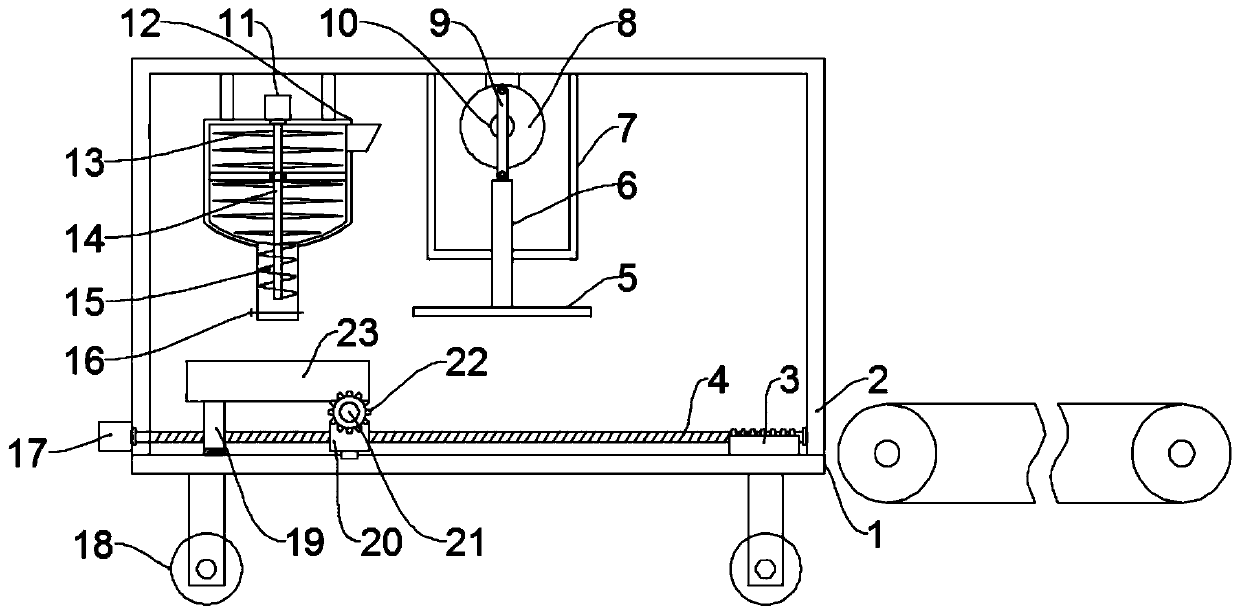

[0024] see figure 1 , in an embodiment of the present invention, an agricultural and animal husbandry waste fuel forming machine includes a base plate 1, a crushing device and a compression device, support legs are installed on the four corners of the bottom of the base plate 1, and rollers 18 are installed at the bottom of the support legs , the roller 18 is a self-locking roller, which facilitates the movement of the device. A gantry 2 is fixed on the upper surface of the substrate 1. A crushing device is installed on the gantry 2. A compression device is installed on one side of the crushing device. The crushing device includes a crushing device. Box 12, first motor 11, rotating shaft 14, crushing blade 13 and auger blade, described crushing box 12 is installed on the portal frame 2, and crushing box 12 is fixedly connected with portal frame 2, and the top of the side wall of crushing box 12 There is a feeding port, the bottom of the crushing box 12 is integrally provided w...

Embodiment 2

[0026] see figure 2 The difference between this embodiment of the present invention and Embodiment 1 is that a fixed rod 26 is provided on one side of the top of the crushing box 12, and the top end of the fixed rod 26 is fixedly connected with the portal frame 2, and the bottom end of the fixed rod 26 is connected with the crushing box 12. Hinged, the other side of the top of the crushing box 12 is located on the gantry 2 and is hinged with an electric push rod 25. The telescopic rod of the electric push rod 25 is hinged with the top of the crushing box 12, and the telescopic rod of the electric push rod 25 is continuously extended and shortened, thereby It can drive the crushing box 12 to swing, so that the crushed waste is spread flat in the collection frame 23 when discharging, which is convenient for subsequent compression, and the compression molding effect is good. The top of the pressing plate 5 is fixed with a second threaded rod 24, the second The threaded rod 24 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com