Automatic stirring spraying device for oil paint

An automatic stirring and spraying device technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of spraying equipment blockage, paint solidification, and influence of paint spraying effect, and achieve the effect of avoiding solidification and improving spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

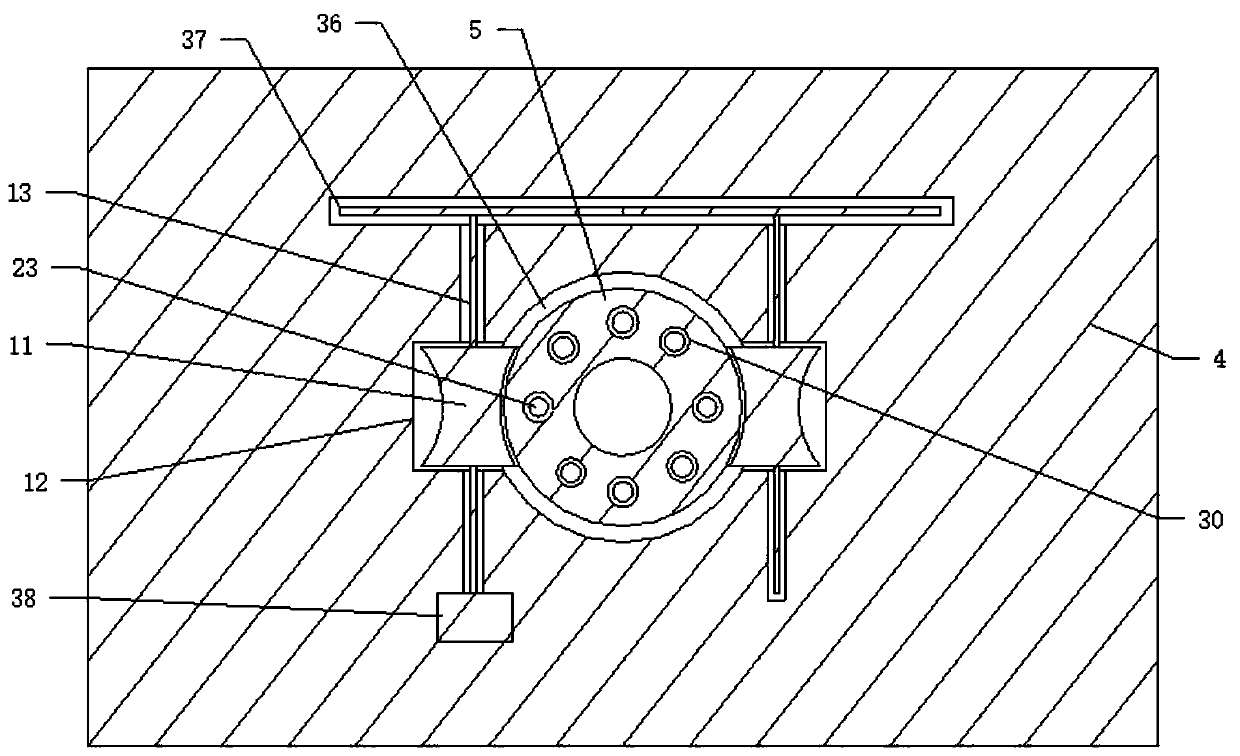

[0027] like Figure 1 to Figure 6As shown, an automatic paint stirring and spraying device includes a fixed base 1, on which a paint bucket 6 is arranged, a sealing cover 7 is arranged on the paint bucket 6, and a paint bucket 6 is arranged on the fixed base 1 A first bracket 2, a second bracket 3 is connected to the first bracket 2, a first control module 4 is connected to the end of the second bracket 3, and a first control module 4 is provided with a The sliding lift shaft 5, the first control module 4 is provided with a second motor 38 that controls the sliding of the lift shaft 5, the lift shaft 5 passes through the sealing cover 7 and slides in the paint bucket 6, so The lifting shaft 5 is provided with a swinging stirring support 8, the other end of the lifting shaft 5 is provided with a third control module 14 that slides on the first control module 4, and the lifting shaft 5 is on the first control module 4. The three control modules 14 rotate upward, and the third c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com