Intelligent essential oilatomizing device

An atomization device and essential oil technology, which is applied in the field of aroma diffusers, can solve the problems of small hole needle diameter, large atomized particles, small mold size, etc., and achieve improved atomization effect, uniform aroma and small atomized particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

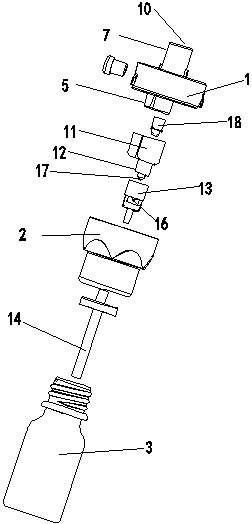

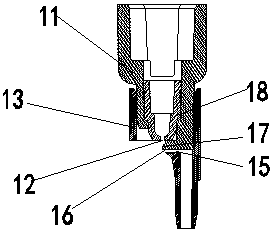

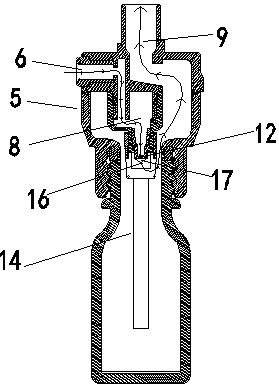

[0021] A kind of intelligent essential oil atomization device of the present invention is described further below with reference to accompanying drawing:

[0022] Such as figure 1 , 2 As shown in , 3, an intelligent essential oil atomization device includes an upper shell 1 and a lower shell 2, the lower edge of the upper shell 1 and the upper edge of the lower shell 2 are interlocked to form an atomization chamber, and the lower portion of the lower shell 2 is sealed and connected to the essential oil bottle 3 On the outer edge of the mouth, the air inlet 4 is located on the side of the cover;

[0023] The center of the upper shell 1 is provided with a vertical central column cavity 5, and the side of the upper shell 1 and the central column cavity 5 in the atomization cavity are provided with an air inlet passage 6 downward, and the central column cavity 5 in the atomization cavity The other side is provided with a mist outlet channel 7, and the mist outlet channel 7 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com