Flour piece pressure-thinning device and crisping machine

A dough sheet and thinning technology, applied in the direction of dough sheeting machine/rolling machine/rolling pin, etc., to achieve the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

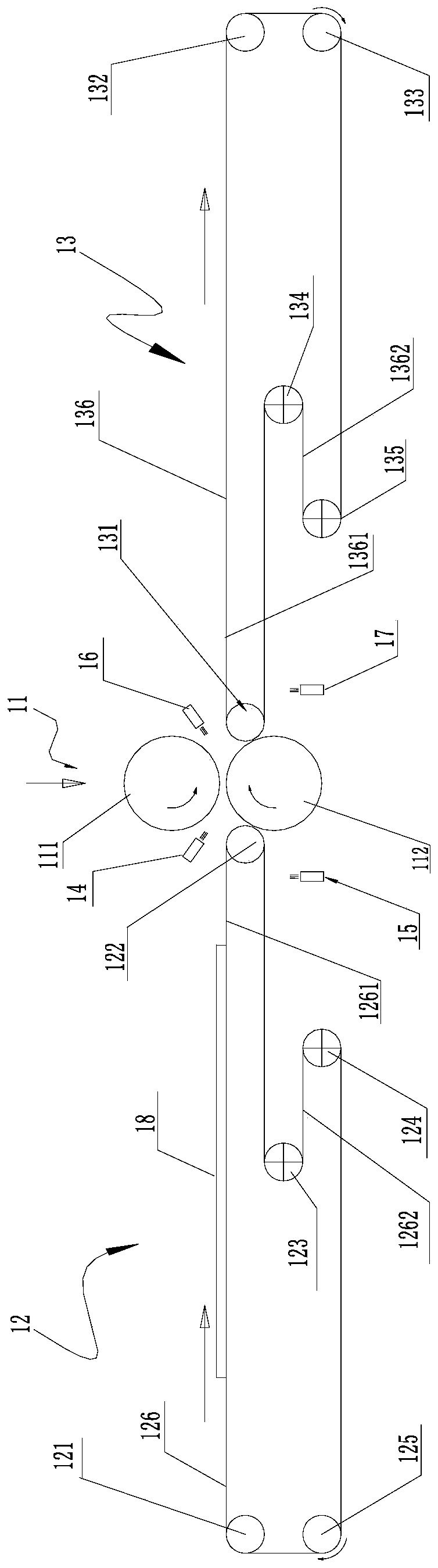

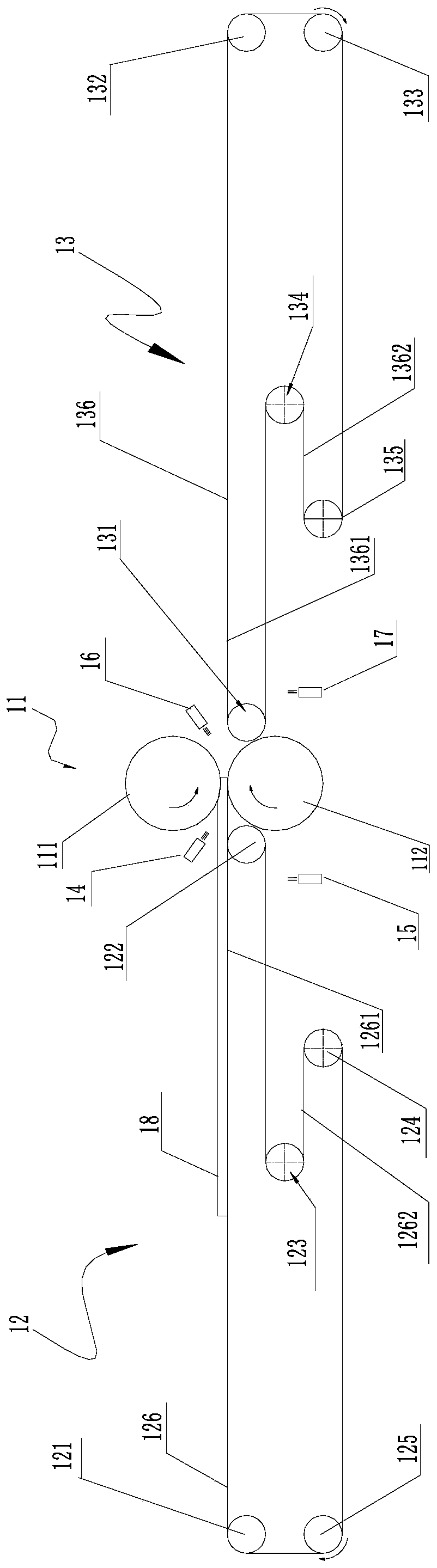

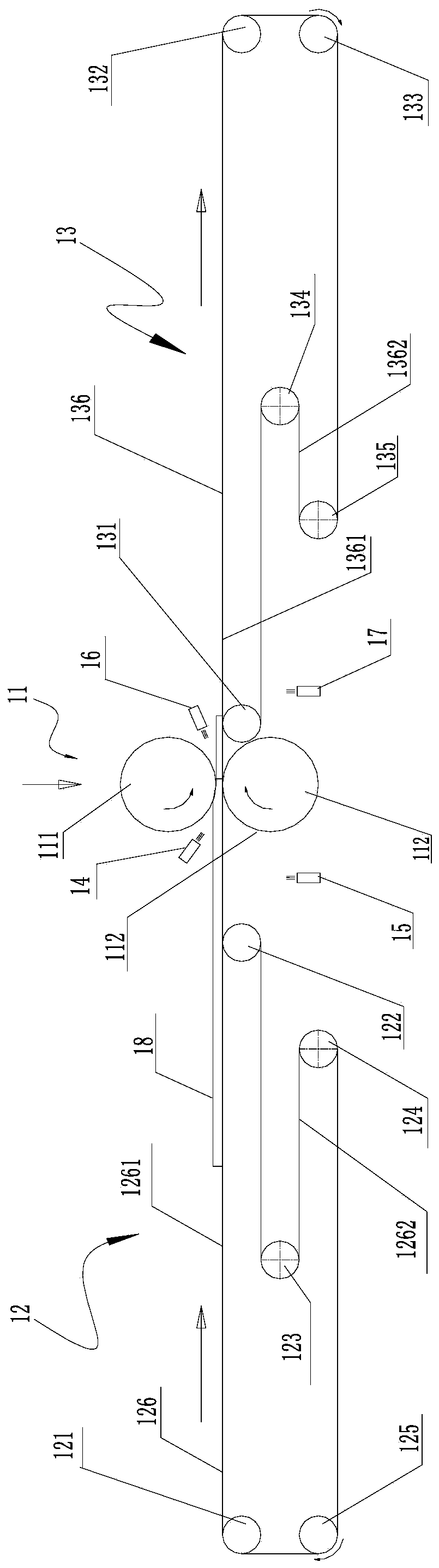

[0053] figure 1 It is a structural schematic diagram of the dough sheet thinning device according to the first embodiment of the present invention, and the arrows in the figure show the conveying direction of the dough sheet. Such as figure 1 As shown, the dough sheet thinning device of the present invention includes a dough sheet pressing device 11, an input device 12 for sending dough sheets 18 into the dough sheet pressing device 11, and receiving and sending output from the dough sheet pressing device 11. The output device 13 of the dough sheet 18, the output end of the input device 12 is formed by the end of the input device 12 close to the dough sheet pressing device 11, and the dough sheet thinning device includes a first mobile drive device (not shown in the figure) shown), the output end of the input device 12 can approach or move away from the dough sheet pressing device 11 in the dough sheet conveying direction driven by the first moving drive device.

[0054] Thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com