Automatic control and linkage protection system for 300 MW nuclear main pump full-flow test bed

A technology of protection system and full flow, which is applied in the field of automatic control and chain protection system, can solve the problems of poor reliability, low degree of automation of test bench, low efficiency, etc., and achieve the effect of improving accuracy, reducing the risk of manual control and misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

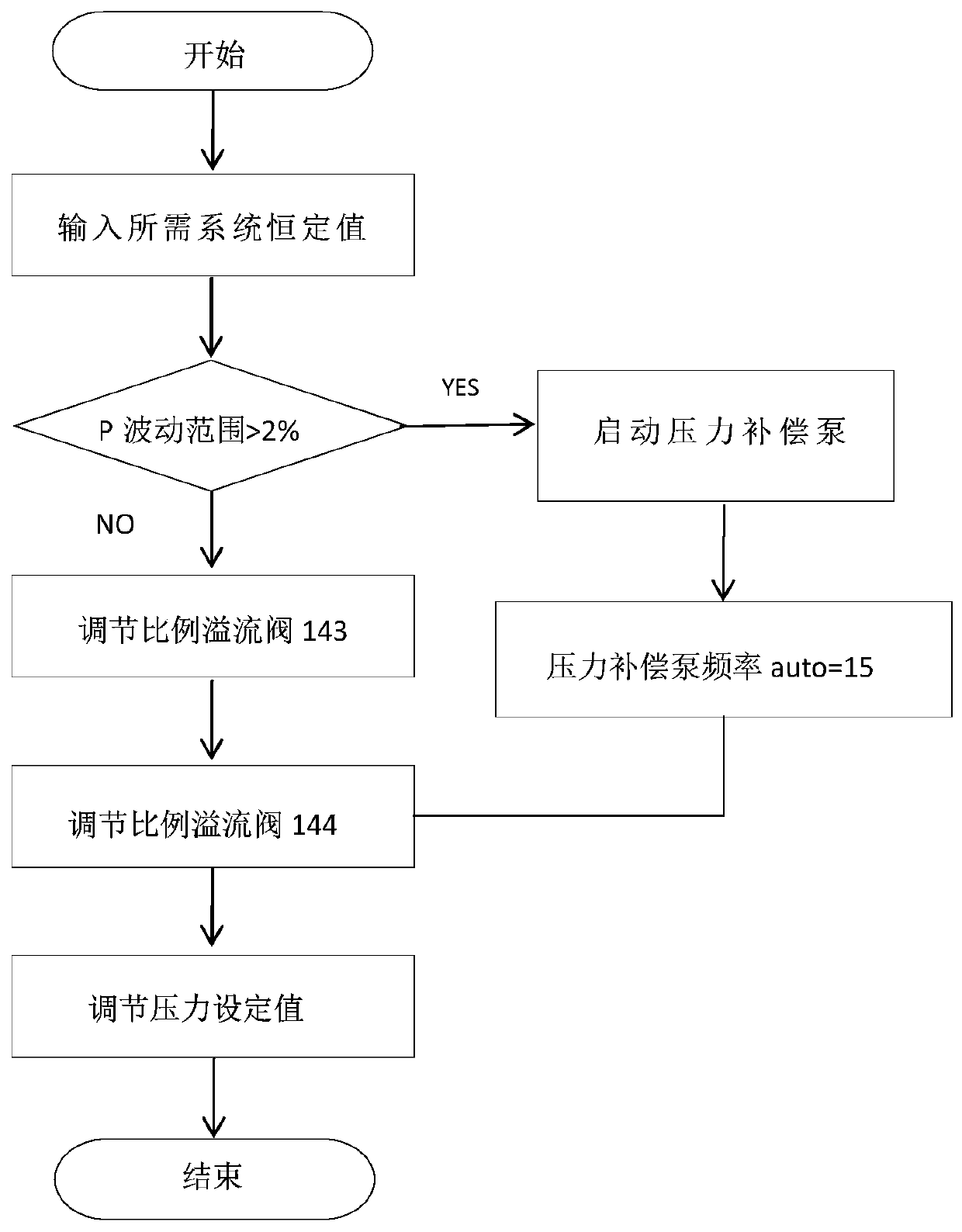

[0062] Such as figure 1 As shown, 1. The system constant pressure adjustment process. The rated working pressure of the test platform is 15MPa, and a pressure compensation pump and proportional relief valve are used to form a two-stage pressure regulation system; the tester manually enters the 15MPa constant pressure value and enters the automatic control , the system will automatically control the pressure to the rated working condition of 15MPa.

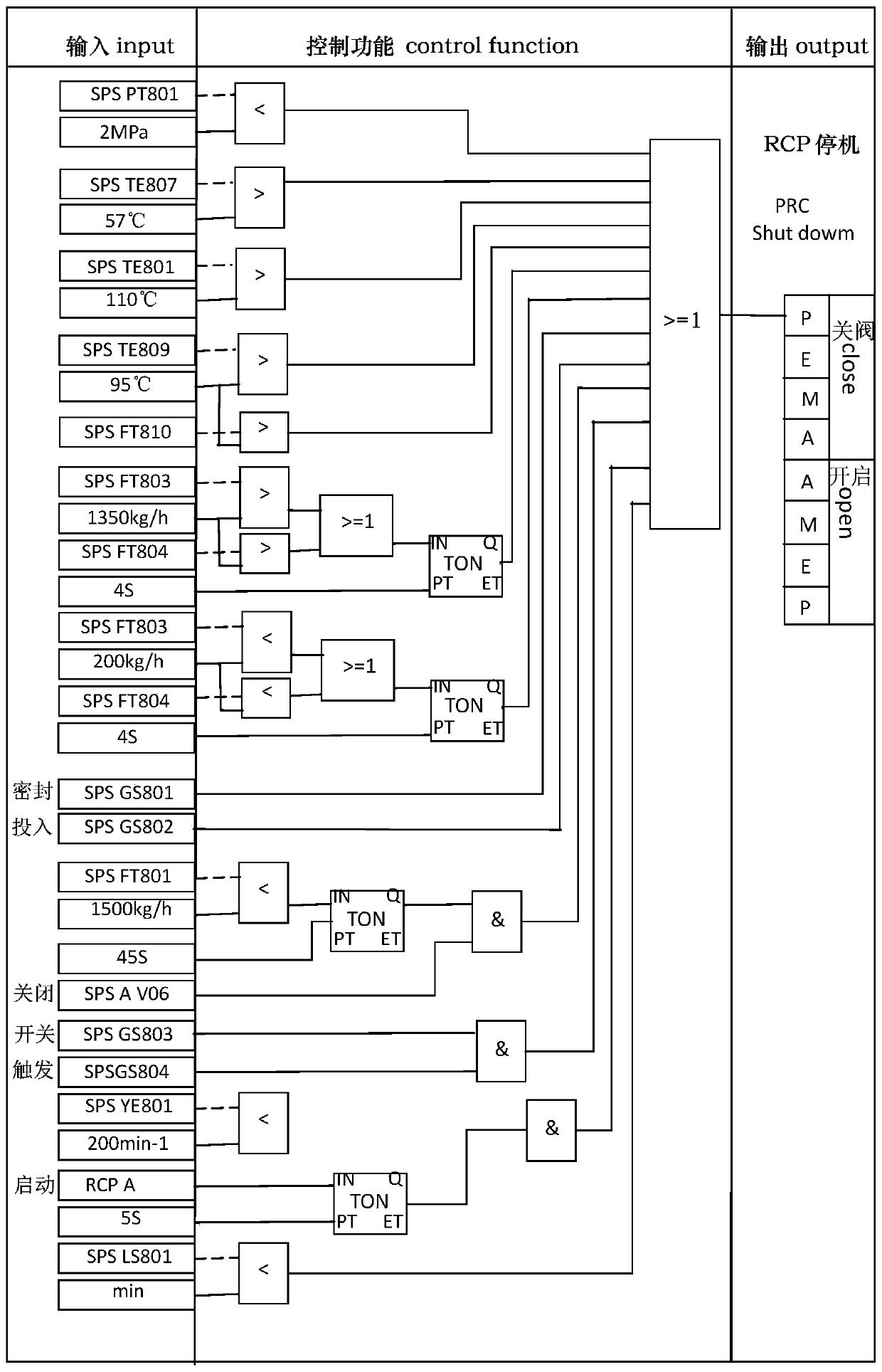

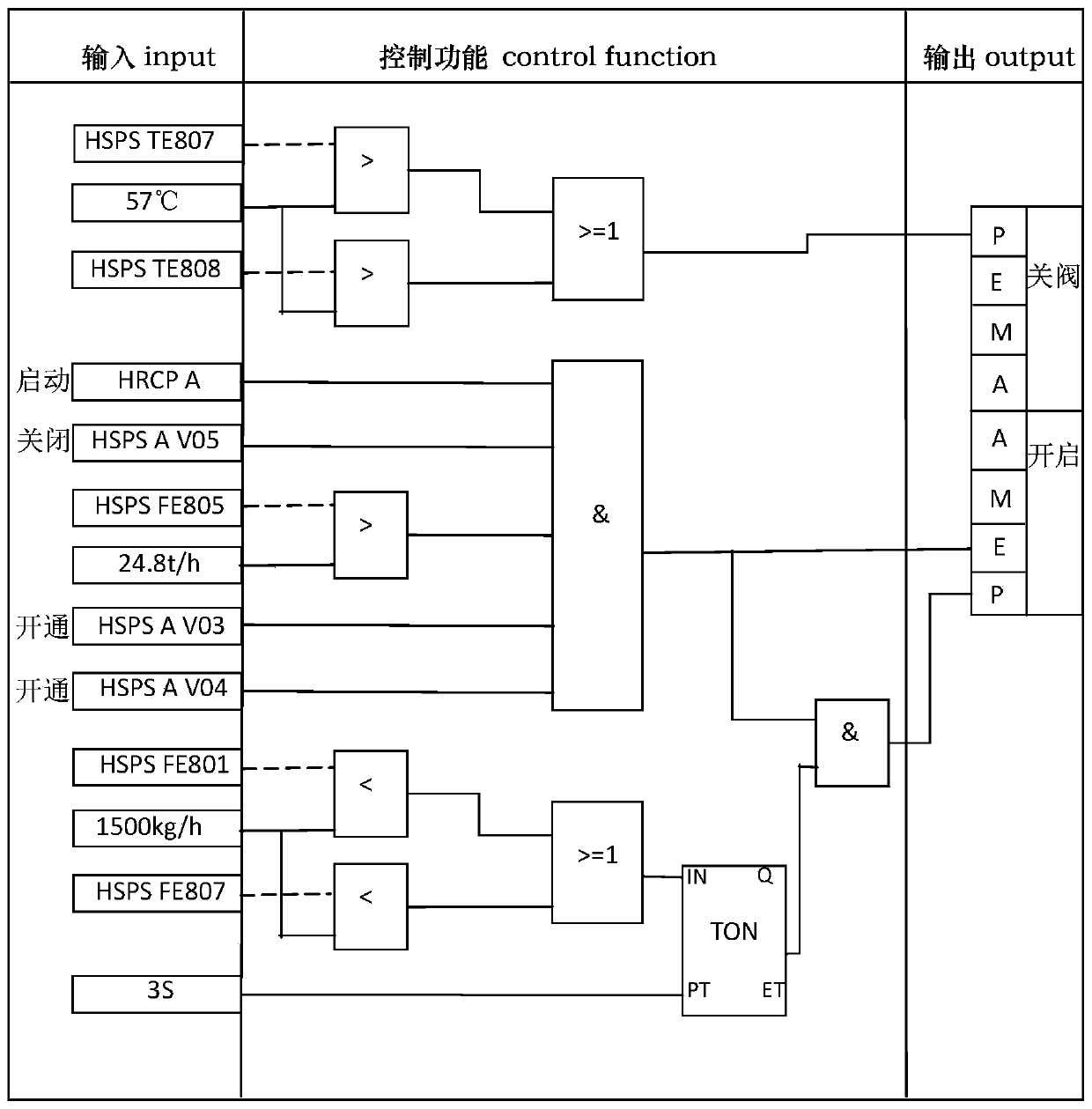

[0063] 2. Main pump stop chain protection system

[0064] Such as figure 2 As shown, before starting the main pump, the tester needs to ensure that the following 14 conditions are not triggered and the automatic shutdown chain is enabled before the machine can be started. If a certain condition is triggered and the chained shutdown condition is enabled before the startup, the main pump will Can not start and trip automatically. The main pump shall be stopped if any of the following given conditions are met;

[0065] 1) SPS PT8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com