A high-pressure or ultra-high-pressure canned pump

An ultra-high pressure, shielded pump technology, used in pumps, pump components, pump devices, etc., to solve problems such as reduced motor efficiency, unreliable sealing, and inconvenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

[0043] Such as figure 1 , the present invention consists of a pump head 6, an impeller 7, a motor housing 4, a motor stator 3, a motor lead assembly 3-1, a shielding sleeve 1, a motor rotor 2, a pump head bearing assembly 5, a rear cover 8, and a rear cover bearing Assembly 10, pressure balance diaphragm 9, support A11-1, support B11-2 constitute.

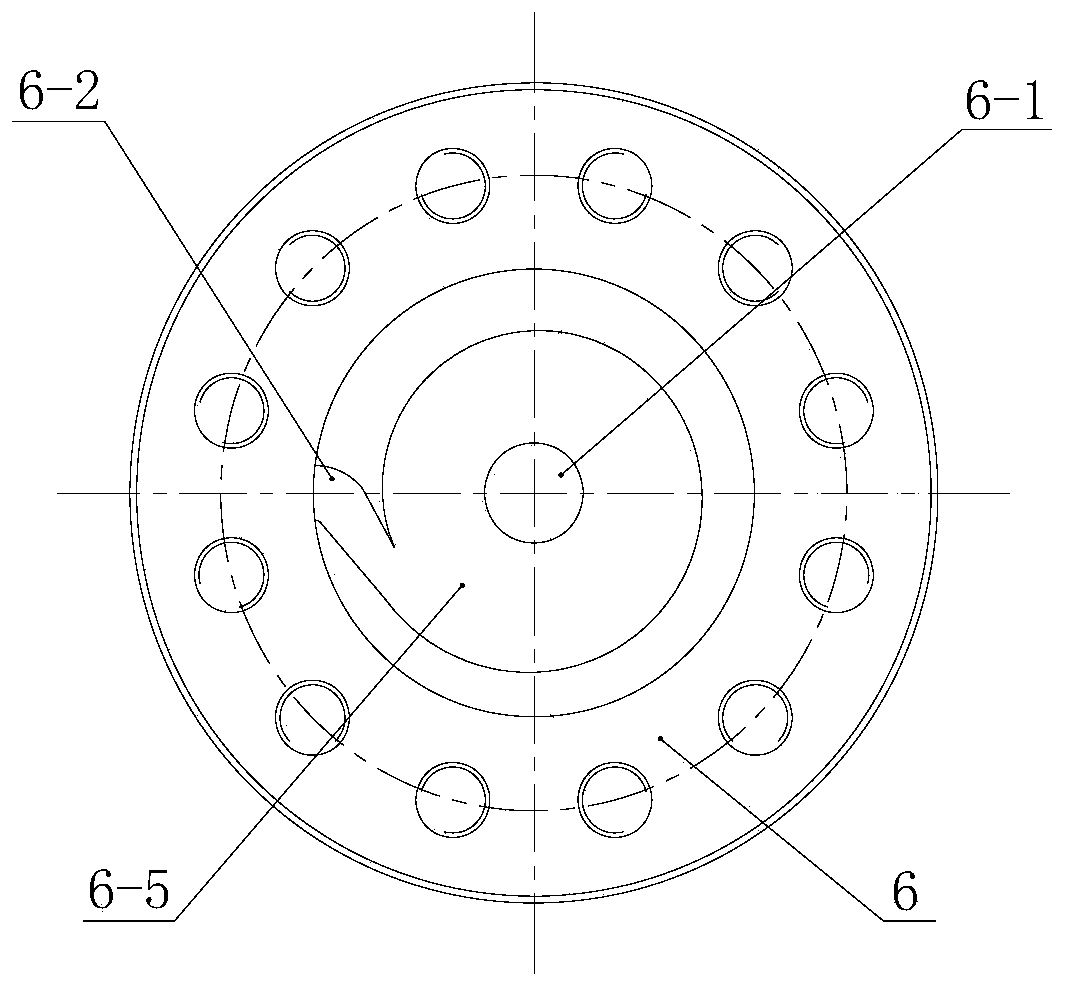

[0044] Such as figure 2 , image 3 As shown, the pump head 6 is a flat cover with a boss. S30408 stainless steel forgings are selected. A through hole is set at the axis of the flat cover as the pump inlet 6-1. The volute chamber 6-5, the volute chamber outlet 6-2 is set on the cylindrical surface of the radial boss of the pump volute chamber 6-5, the bottom of the cylindrical surface of the boss is provided with 2 sealing grooves, and the flat cover is evenly distributed on the electric pump 6 bolt ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com